Heat exchange structure of gas dryer

A technology of gas drying and heat exchange structure, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., which can solve the problems of easy freezing of condensed water, complicated manufacturing process and high cost, and improve the utilization of cooling capacity High efficiency, simple overall structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

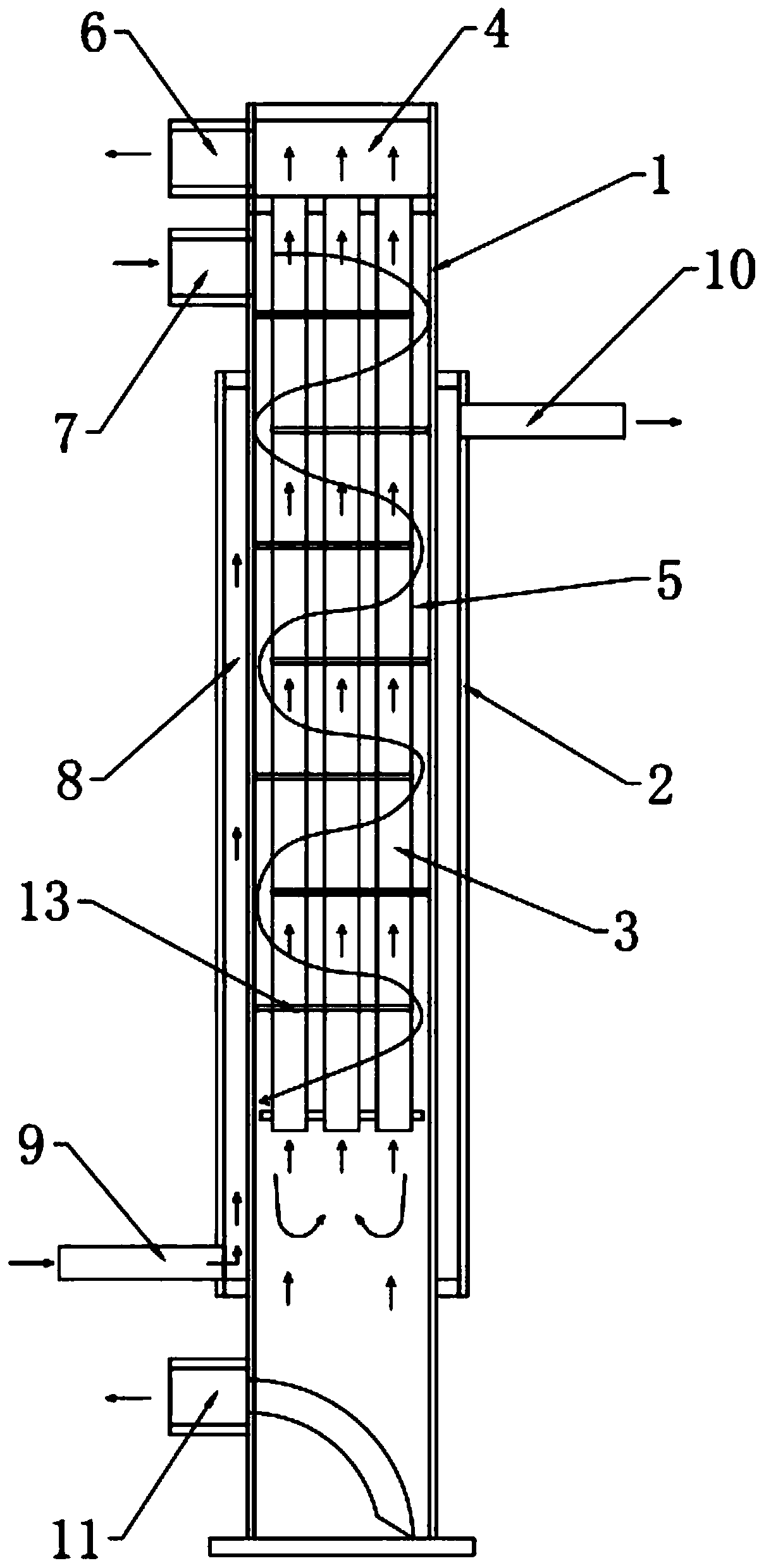

[0021] Embodiment 1: as figure 1 As shown, the heat exchange structure of a gas dryer described in this embodiment, which can be used to filter compressed air and gas, includes a vertically arranged first tube 1 and a sleeve on the outside of the first tube 1 In the second tube 2, more than one third tube 3 is arranged in the cavity of the first tube 1 along its length direction, and these third tubes 3 are evenly distributed. Both the top and the bottom of the first tube 1 and the second tube 2 are sealed, and the upper part of the inner cavity of the first tube 1 is sealed to form a first inner cavity 4 at the top and a second inner cavity 5 at the bottom. The first inner cavity 4 and the second inner cavity 5 are separated from each other, and a gas outlet 6 and a gas inlet 7 connected to the outside world are respectively provided above and below the sealing place, and the gas inlet 7 and the gas outlet 6 are opened along the horizontal direction. The gas inlet 7 communi...

Embodiment 2

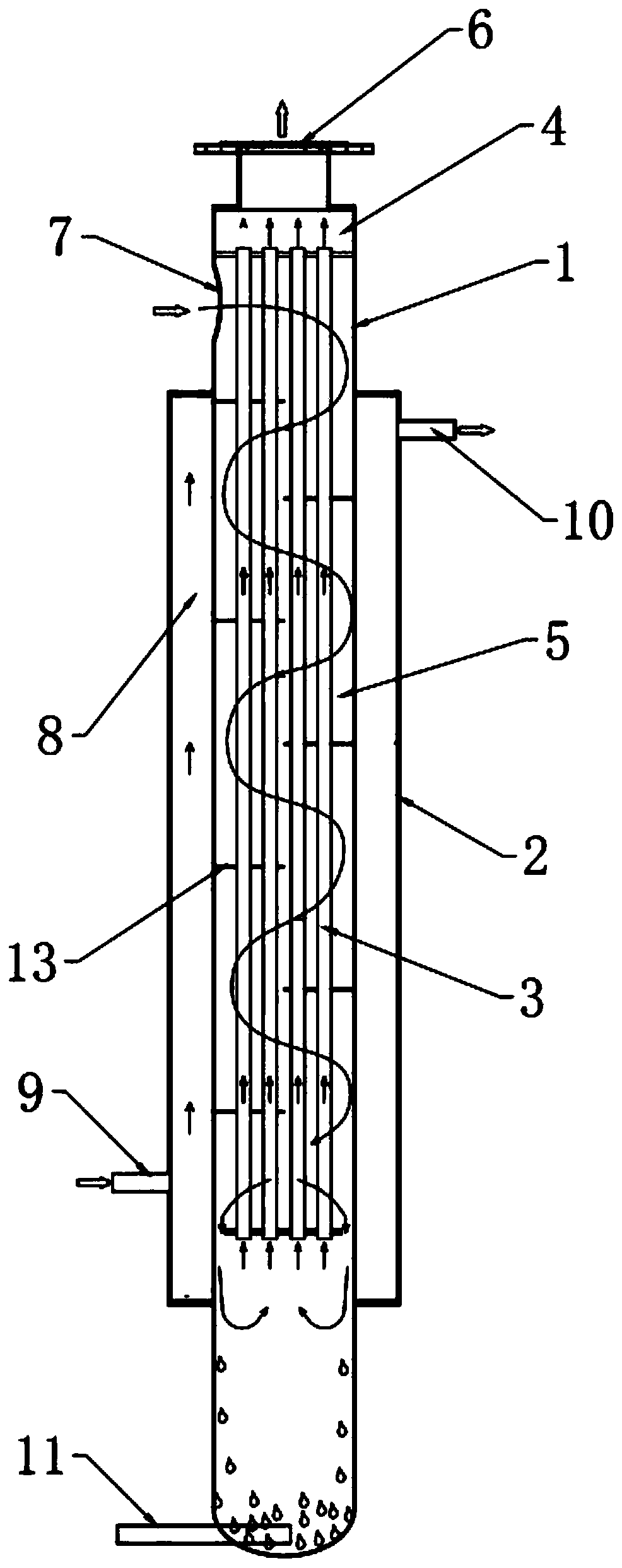

[0023] Embodiment 2: refer to figure 2 , Compared with Embodiment 1, the difference is that: the gas inlet 7 is arranged to open in the horizontal direction, and the gas outlet 6 is arranged to open upward.

Embodiment 3

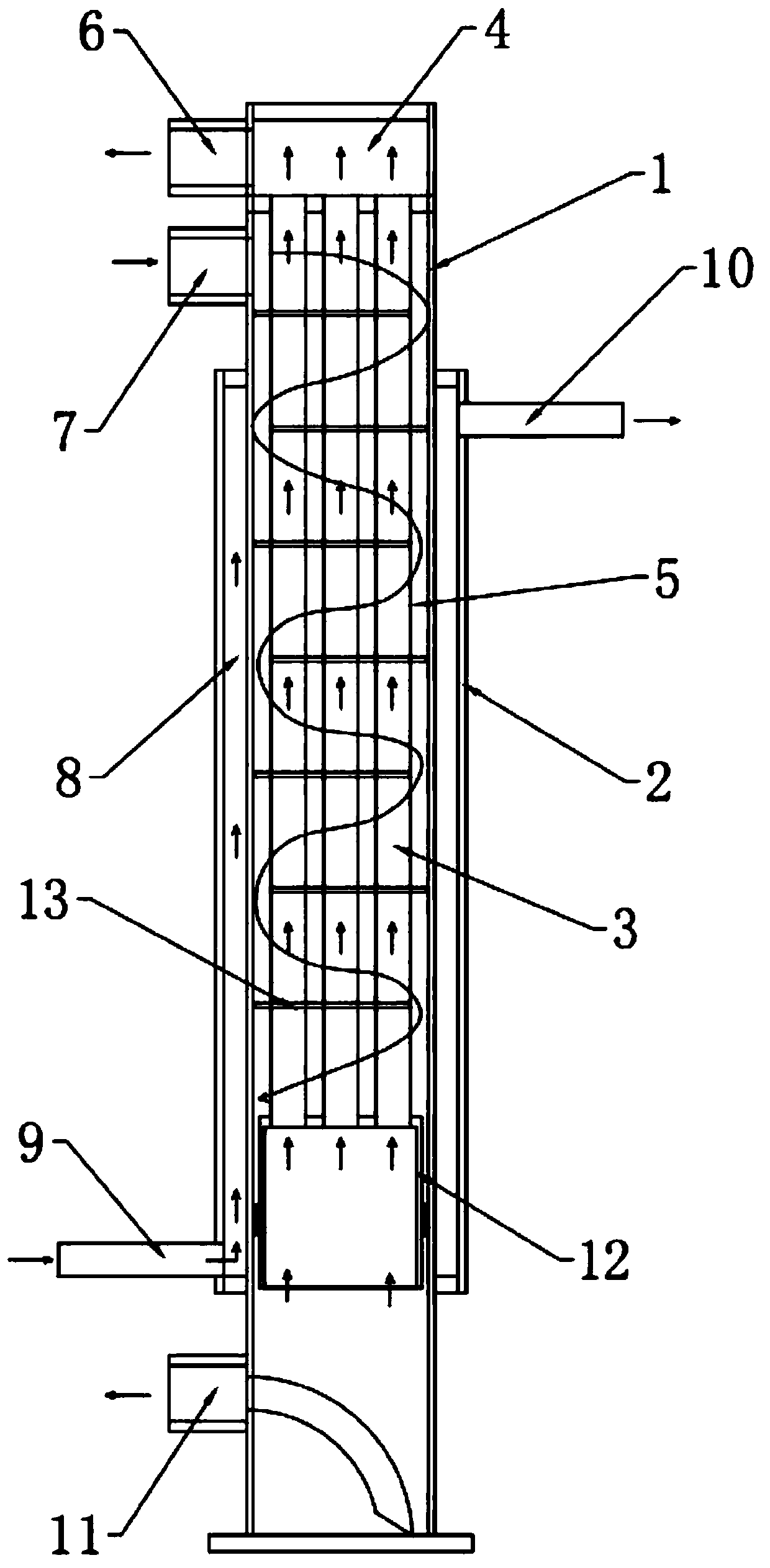

[0024] Embodiment 3: refer to image 3 , with respect to embodiment 1, its difference is: the bottom end of described third pipe 3 is connected with the fourth pipe 12 of " 冂 " type section, and the top of fourth pipe 12 is sealed, and the bottom is open, and described third pipe 3 The bottom end passes through the top of the fourth tube 12 and communicates with the second inner cavity 5. The fourth tube 12 is preferably coaxially arranged with the first tube 1, and the outer wall of the fourth tube 12 is connected with the first tube 1. A channel is formed between the inner walls of the first tube 1 to force the gas to flow against the inner wall of the first tube 1. The position of the fourth tube 12 is within the length of the second tube 2, because the third inner chamber 8 has refrigerant, and the second The gas in the inner cavity 5 flows close to the inner wall of the first tube 1, and the distance between the gas and the refrigerant is short, and the heat exchange effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com