Multi-cycle indirect evaporative cooling water supply device and cold water preparation method thereof

A cold water device, multi-circulation technology, applied in space heating and ventilation, heating methods, household heating and other directions, can solve the problems of large equipment height and size, low utilization rate of cooling capacity, waste of cooling energy, etc., and achieve high energy efficiency ratio , the structure is reasonable, the effect of reducing the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

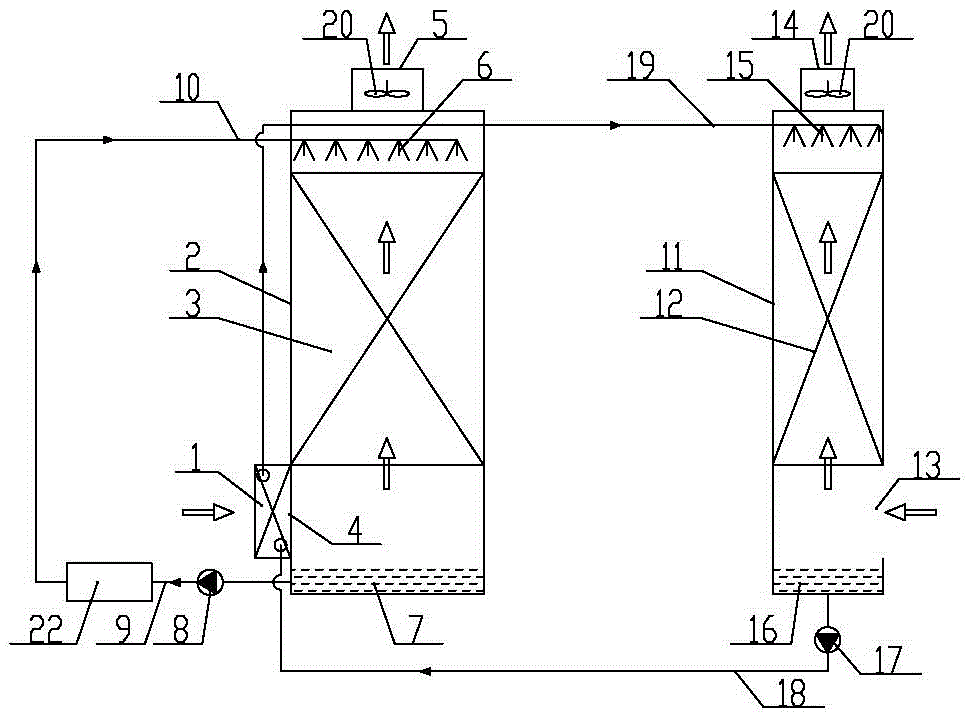

[0039] Embodiment 1: as attached figure 1 As shown, the multi-cycle indirect evaporative cooling water supply device includes no less than two circulating cooling water devices, wherein the first circulating cooling water device includes a first surface cooler 1, a first shell 2, and a first evaporative cooling filler 3 , the first spraying device 6 and the first circulating water tank 7, the first housing 2 is provided with the first air inlet port 4, the water outlet of the first circulating water tank 7 is connected with the first water supply pipe with the first circulating pump 8 9. The water inlet of the first spraying device 6 is connected to the first return pipe 10; the second circulating cooling water supply device includes a second shell 11, a second evaporative cooling filler 12, a second spraying device 15 and a second circulating water tank 16. The second housing 11 is provided with a second air inlet port 13; the first surface cooler 1 is installed at the first ...

Embodiment 2

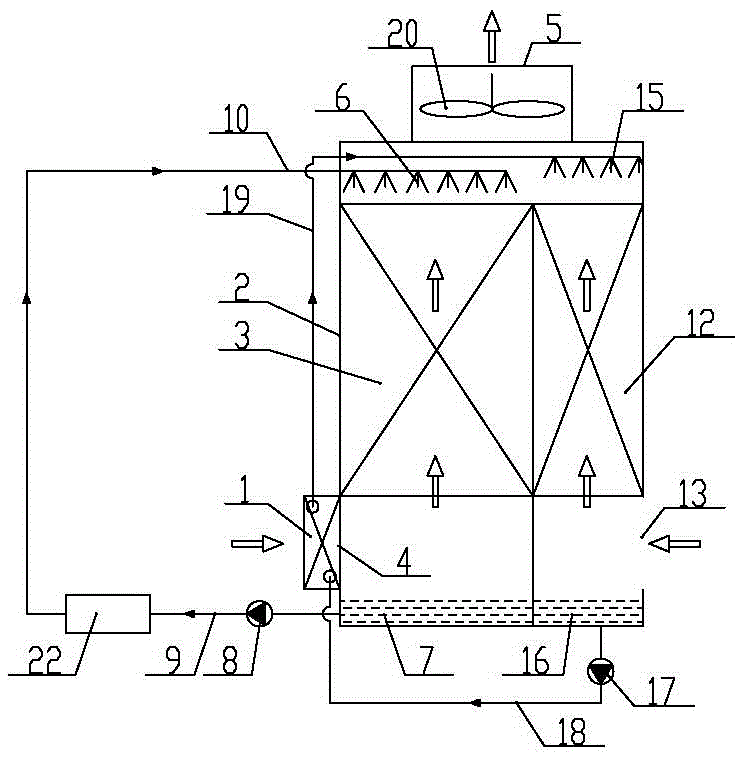

[0045] Embodiment 2: as attached figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the first housing 2 and the second housing 11 of Embodiment 2 are integrated, and the first exhaust port 5 and the second exhaust port are integrated. of the exhaust port. The first casing 2 and the second casing 11 are made into an integrated casing, which has a more compact structure and takes up less space. When the first air exhaust port 5 and the second air exhaust port are an integral air exhaust port, a common exhaust fan 20 is installed at the integral air exhaust port.

Embodiment 3

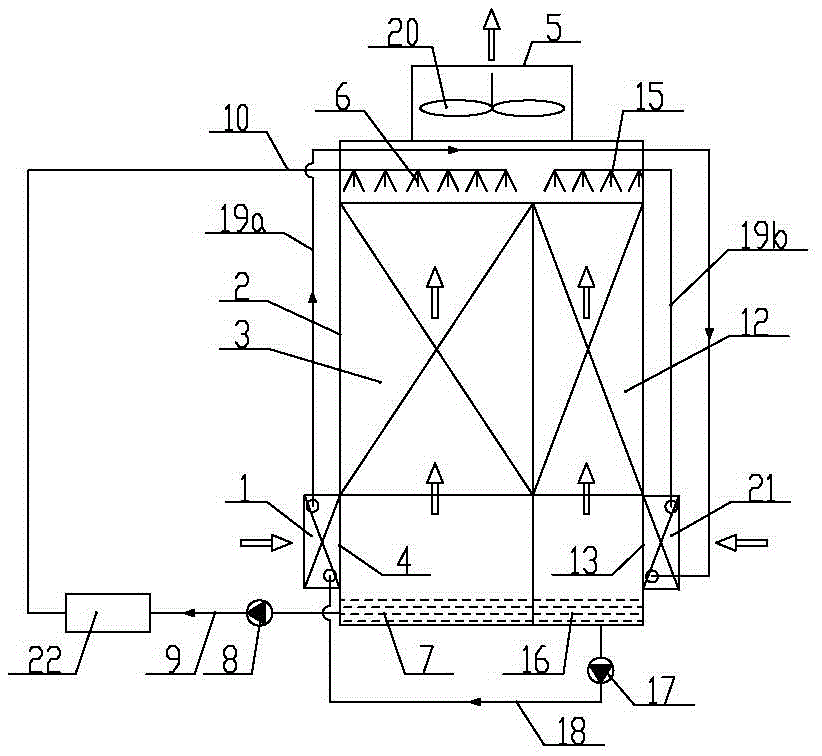

[0046] Embodiment 3: as attached image 3 As shown, the difference between embodiment 3 and embodiment 2 is that a third surface cooler 21 is installed at the second air inlet port 13 of embodiment 3, and the second water return pipe 19 includes the first pipe section 19a of the second return water pipe And the second pipe section 19b of the second return pipe, the water inlet of the third surface cooler 21 communicates with the water outlet of the first surface cooler 1 through the first pipe section 19a of the second return pipe, and the water outlet of the third surface cooler 21 passes through The second pipe section 19b of the second water return pipe communicates with the water inlet of the second spraying device 15 . Before use, connect the first user heat exchange end 22 with the first water supply pipe 9 and the first return water pipe 10; the outdoor air enters the second evaporative cooling filler through the second air inlet port 13 after passing through the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com