High-efficiency multi-stage throttling natural gas liquefaction equipment and preparation method of liquefied natural gas

A natural gas and high-efficiency technology, which is applied in the field of high-efficiency multi-stage throttling natural gas liquefaction equipment and the preparation of liquefied natural gas, can solve the problems of high entropy loss of compressors, complex structure, low utilization rate of cooling capacity of refrigeration cycle, etc., and achieve high shaft power , Improve liquefaction efficiency, improve the effect of cooling capacity utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

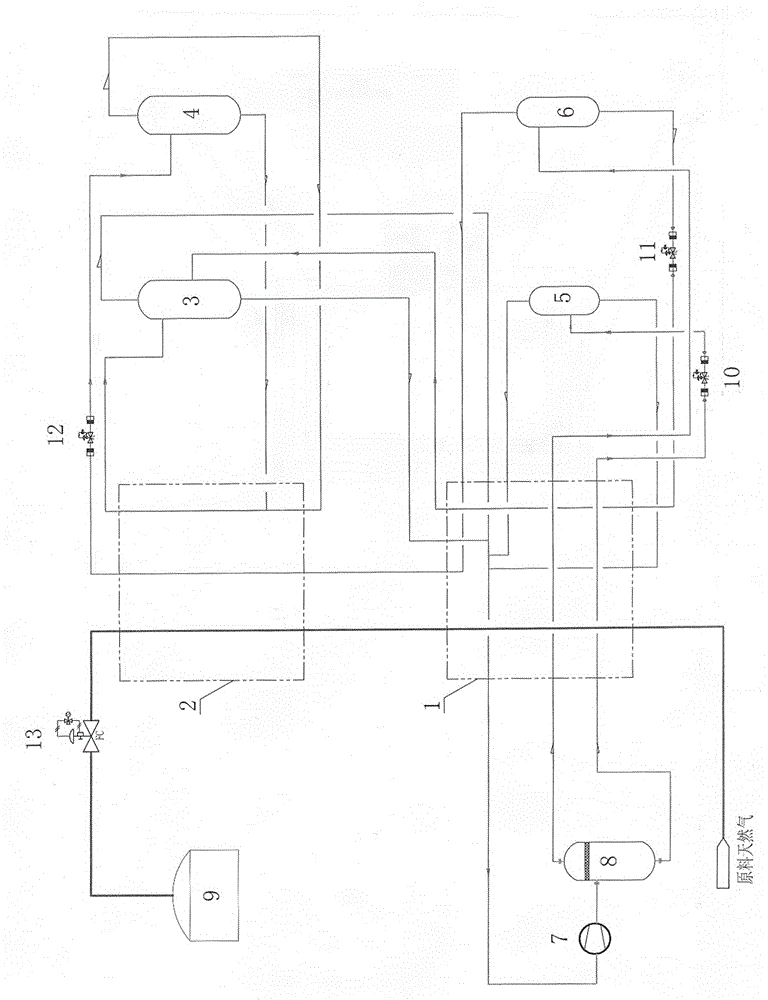

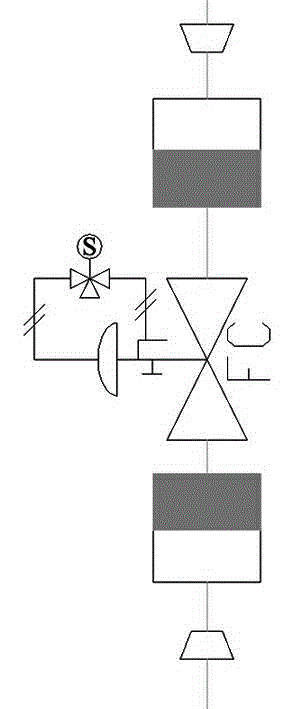

[0021] according to Figure 1~2 The specific structure of the present invention will be described in detail. The high-efficiency multi-stage throttling natural gas liquefaction equipment includes natural gas feed pipes, LNG storage tanks, refrigerant compressors, refrigerant separation tanks, and cold boxes. Among them, the cold box is provided with a main heat exchanger 1 and a secondary heat exchanger 2, and the natural gas feed pipe passes through the main heat exchanger 1 and the secondary heat exchanger 2 in turn and is connected with the feed port of the LNG storage tank 9, and the secondary heat exchanger A fourth throttle valve 13 is provided between the heater and the LNG storage tank 9 .

[0022] There are five refrigerant separation tanks, the outlet of the refrigerant compressor 7 is connected to the feed port of the fifth refrigerant separation tank 8, and the gas phase outlet of the fifth refrigerant separation tank 8 is connected to the feed of the second refri...

Embodiment 2

[0036] The equipment structure and preparation process are the same as in Example 1, wherein the molar content of each component in the refrigerant is: 15% nitrogen, 30% methane, 30% ethylene, 10% propane, and 15% isopentane.

Embodiment 3

[0038] The equipment structure and preparation process are the same as in Example 1, wherein the molar content of each component in the refrigerant is: 20% nitrogen, 25% methane, 25% ethylene, 15% propane, and 10% isopentane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com