Vibration monitoring method, vibration monitoring device, driving system, industrial control equipment and storage medium

A vibration system and vibration monitoring technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of human cost prone to errors and need labor, and achieve the effect of improving accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

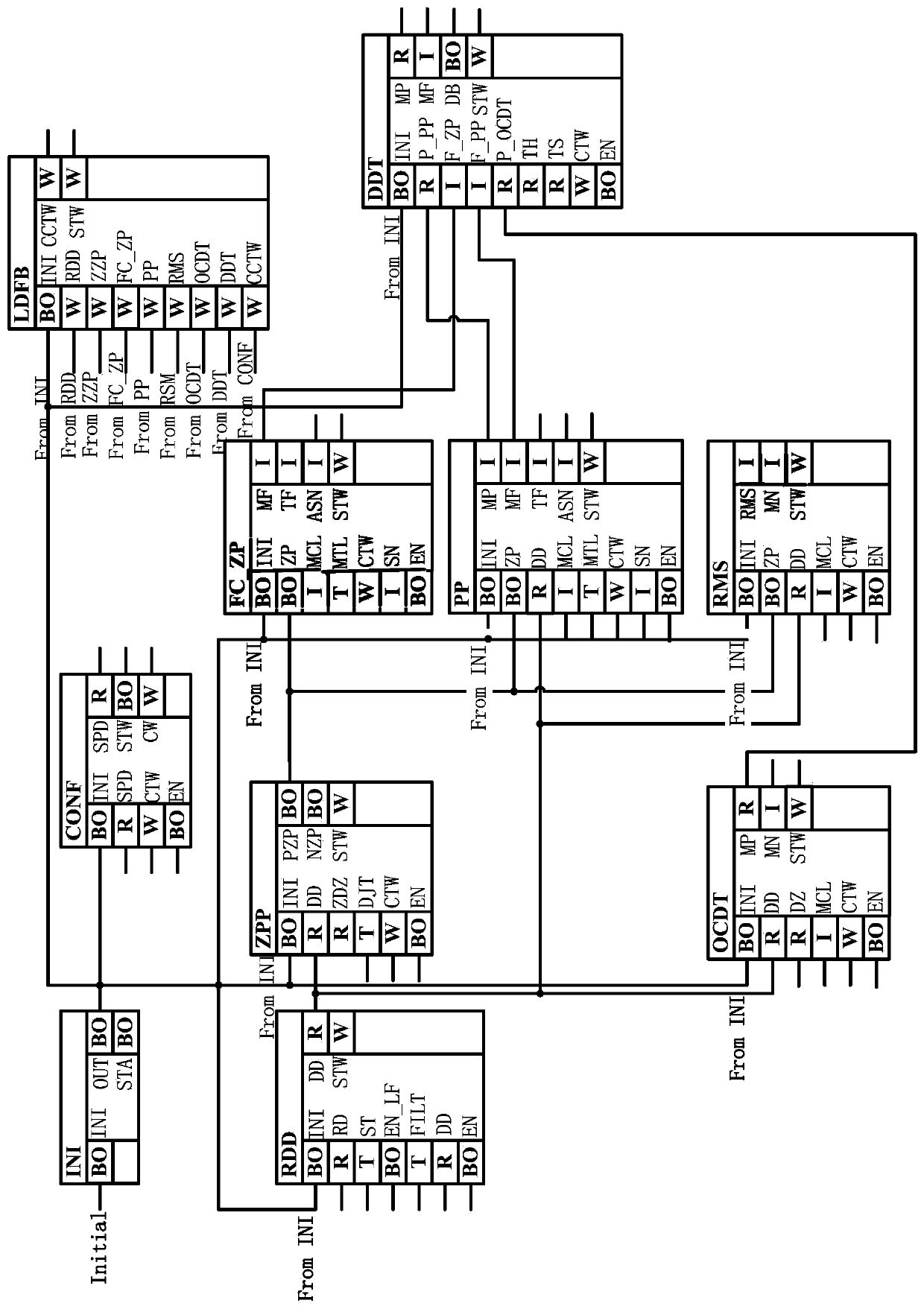

[0070] As mentioned above, vibration monitoring through vibration sensors or manual methods leads to high cost of existing vibration monitoring, and in some special application environments, it is even impossible to install corresponding vibration sensors. In addition, due to the influence of various external environmental factors, using external vibration sensors or manual methods for vibration monitoring often results in inaccurate vibration monitoring results.

[0071] In the embodiment of the present invention, a callable file for vibration monitoring is set in the vibration system, so that the corresponding vibration monitoring can be performed according to the low-frequency periodic vibration signal obtained in real time by the vibration system where the callable file is located. The embodiment of the present invention does not require additional hardware devices such as vibration sensors to analyze and process the low-frequency periodic vibration signals of the vibration...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap