Workpiece pose recognition method based on quadric surface features

A technology of quadratic surfaces and recognition methods, applied in image data processing, instruments, calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

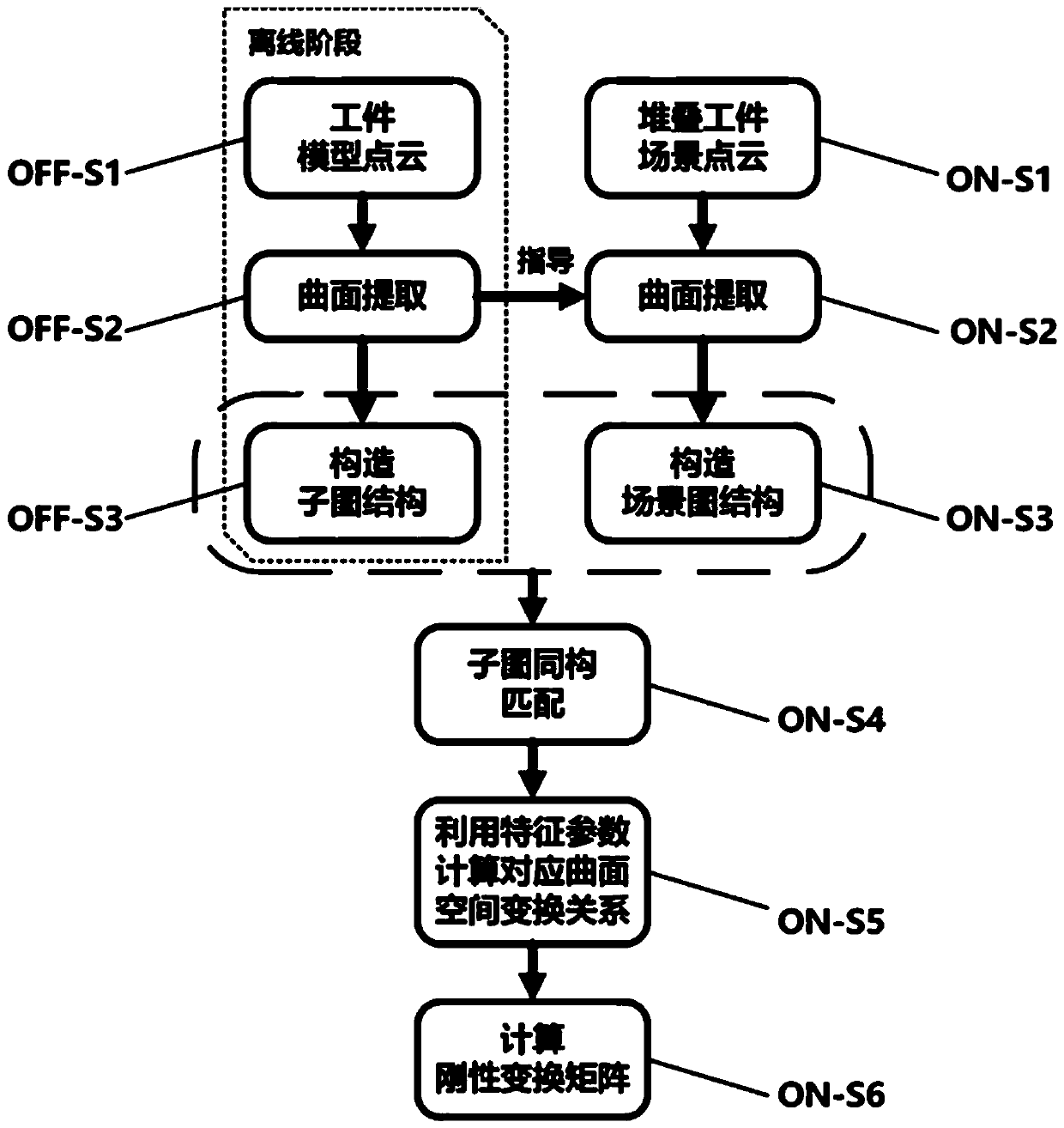

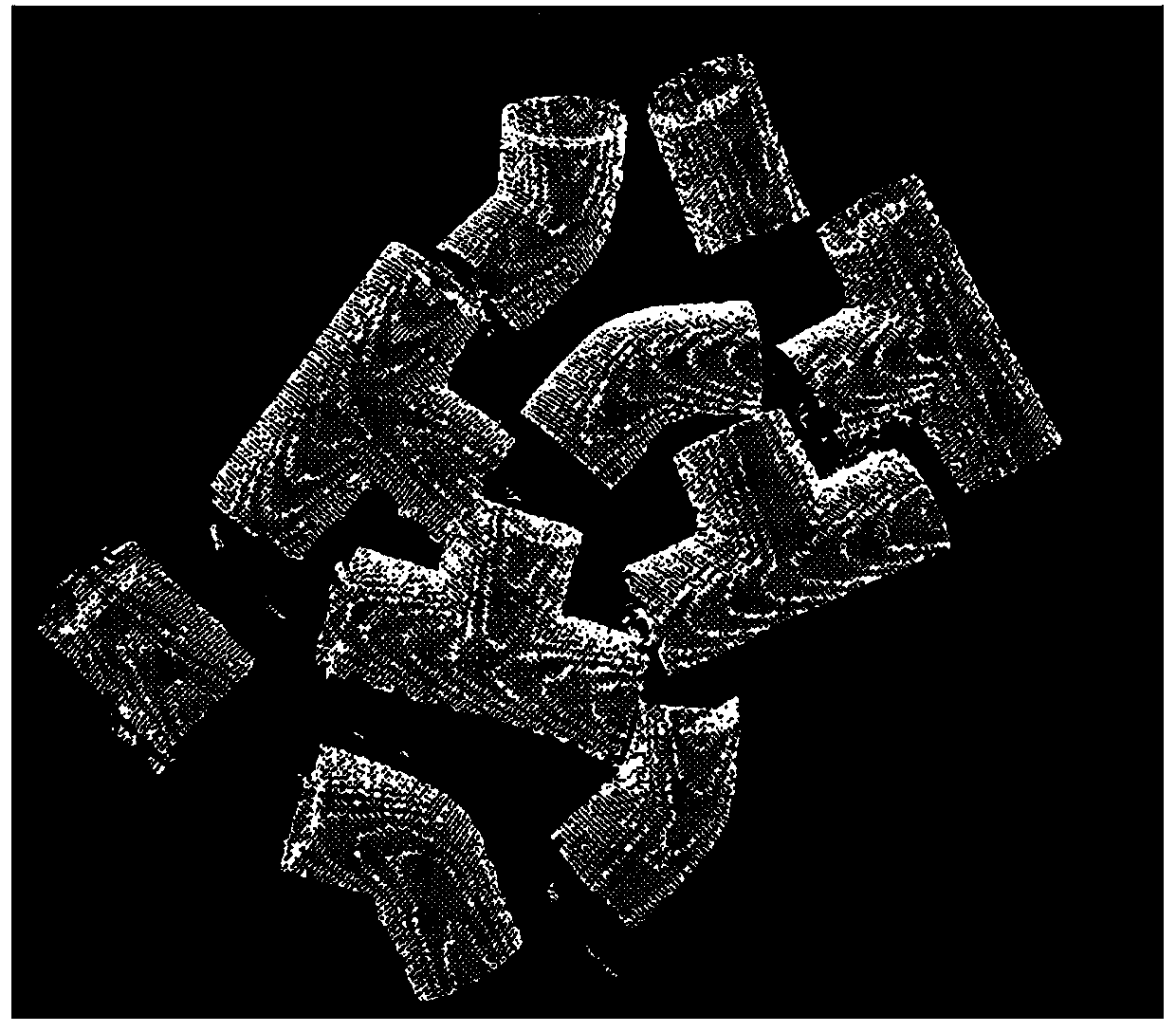

[0051] Such as figure 1 As shown, this embodiment provides a workpiece pose recognition method based on quadratic surface features, which is mainly divided into two parts: offline training and online pose recognition. The surface parameters to be extracted are set during offline extraction, and the online phase will be Extract all the surfaces of this parameter, including the following steps:

[0052] Offline building model subgraph refers to the preparation stage before the operation of the robot, which is only processed once:

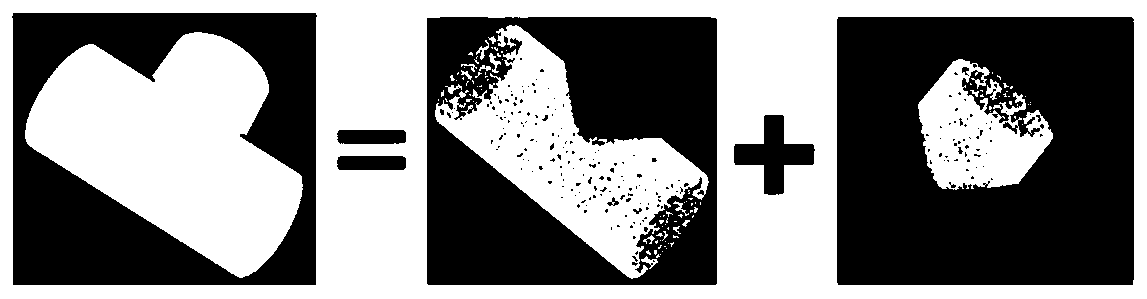

[0053] (1) Read the model point cloud data, such as figure 2 As shown, the model of the present embodiment adopts the tee pipe parts model;

[0054] (2) Split the specified quadratic surface from the model, and calculate the spatial geometric relationship between the quadric surface characteristic parameters and the quadric surface, the centroid distance, etc. The spatial geometric relationship includes the distance relationship between points and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com