Automatic cleaning device of viscosity meter

An automatic cleaning and cleaning device technology, applied in the directions of cleaning hollow objects, drying gas arrangement, cleaning methods and utensils, etc., can solve the problems of low solvent recovery rate, limited heating cleaning effect, complicated operation, etc., to improve the orderly The effect of stability, easy replacement, and reducing the probability of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

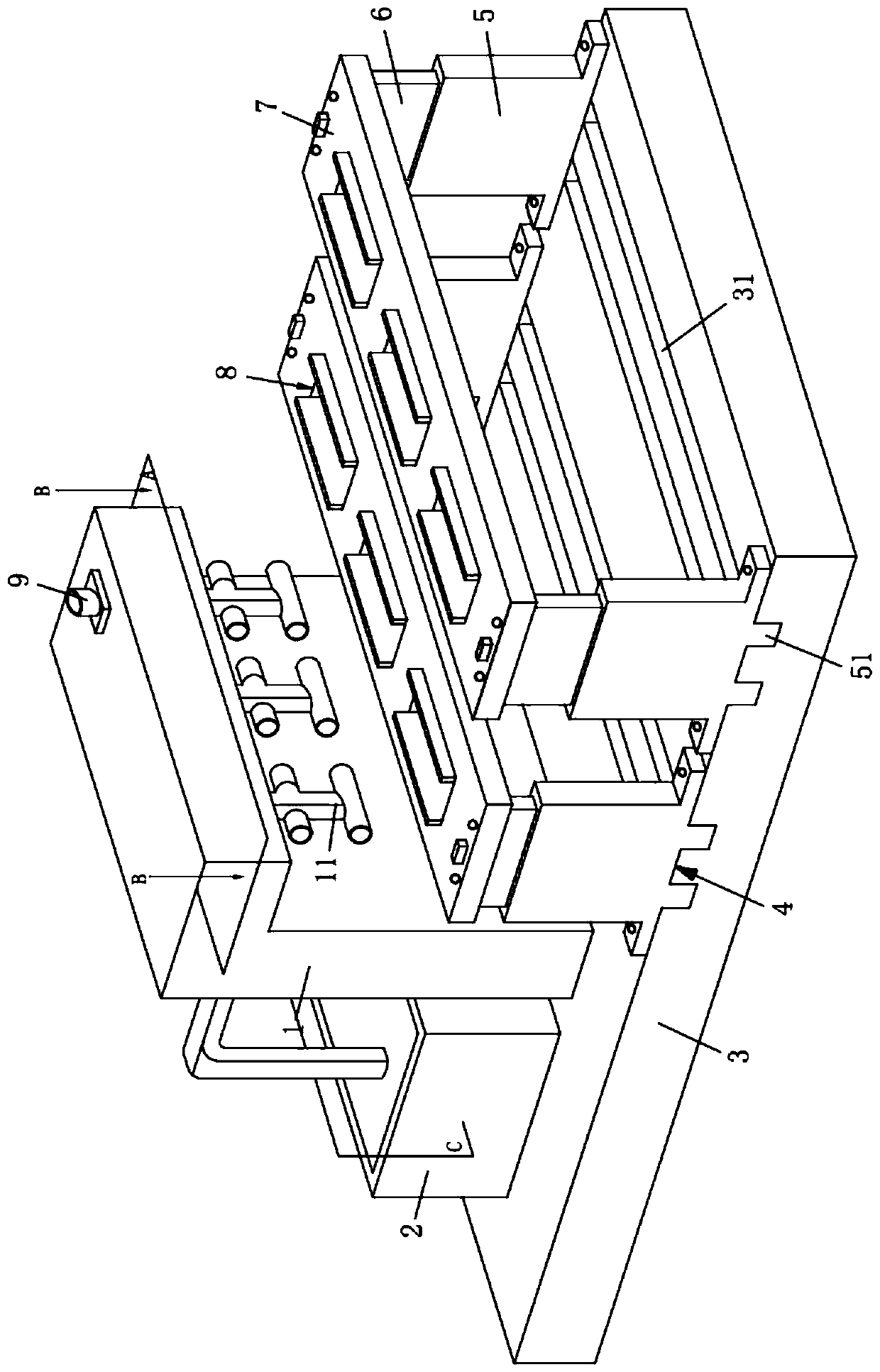

[0029] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

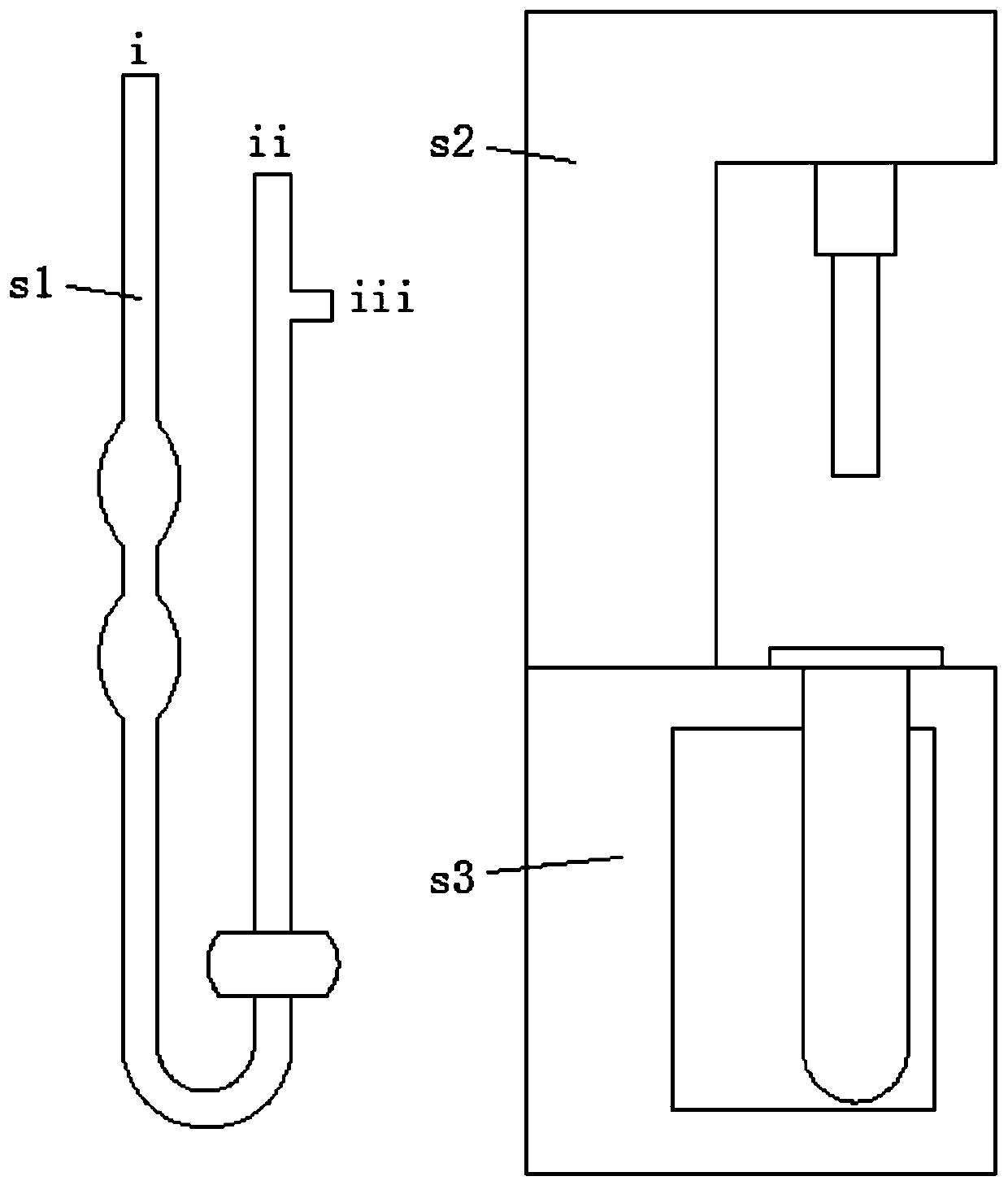

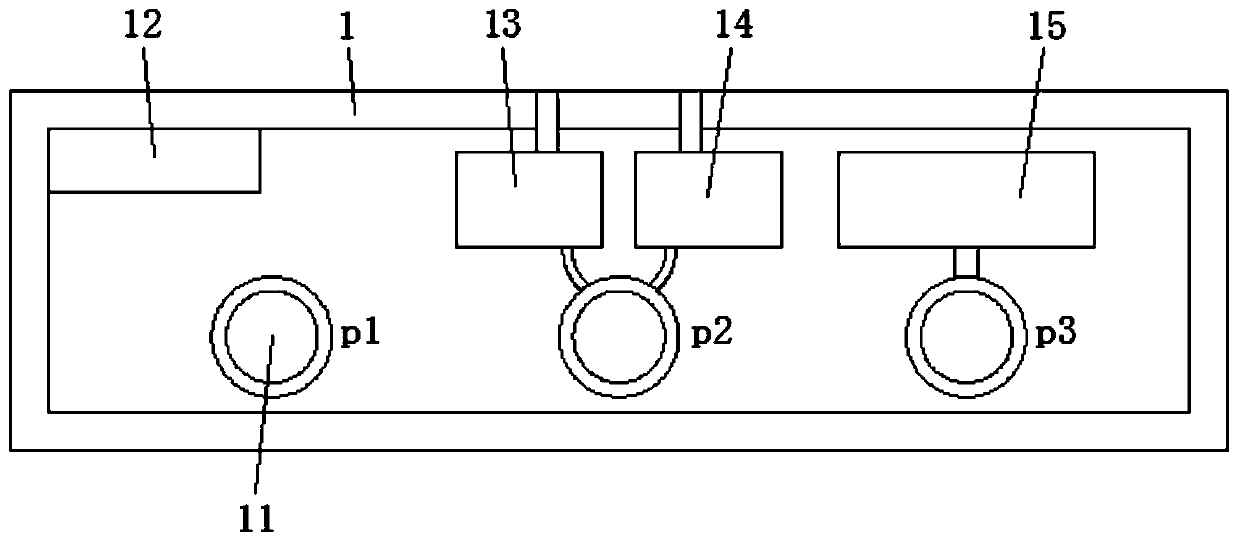

[0030] Such as Figure 2-Figure 7 As shown, an automatic cleaning device for a viscometer includes a base 3, a storage box 2 installed on the top of the base 3 in sequence, a cleaning device 1 and a pipe rack 4, the cleaning device 1 has an L-shaped structure, and the inside of the cleaning device 1 A controller 12, a hot air blower 13, an air compressor 14, a vacuum pump 15 and a cleaning pipe 11 are installed clockwise. There are three cleaning pipes 11, and the three cleaning pipes 11 are respectively the first inlet pipe, the second inlet pipe and the cleaning pipe 11. Out of the pipe, the hot air blower 13 is connected with the second inlet pipe, the air compressor 14 is connected with the second inlet pipe, the vacuum pump 15 is connected with the outlet pipe, and the bottom ends of the three cleaning pipes 11 extend to the outside of the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com