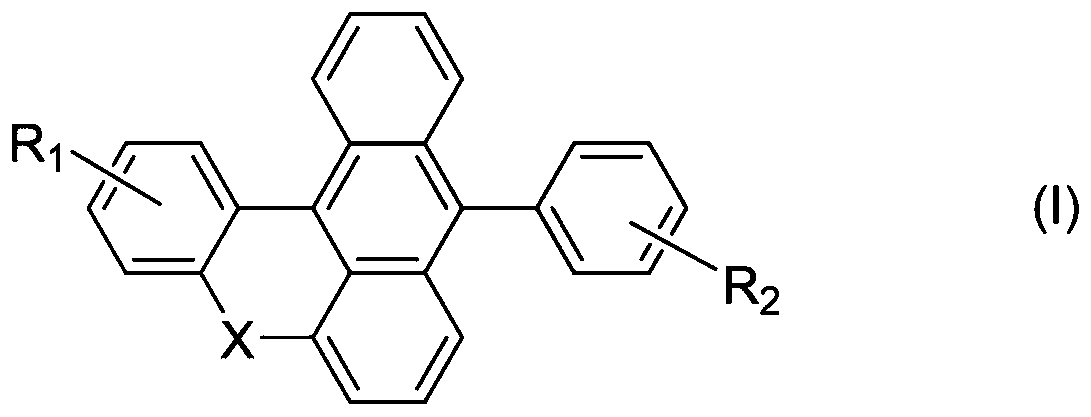

Condensed ring type blue light main body material and application thereof and preparation of application device

A blue-light main material and main material technology, applied in the field of condensed-ring blue-light main materials, its application and the preparation of application devices, can solve the problems of difficult to achieve deep blue light emission and high-efficiency operation, low color purity of blue light, etc., and achieve good light emission effect, high blue light purity, and the effect of improving blue light luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

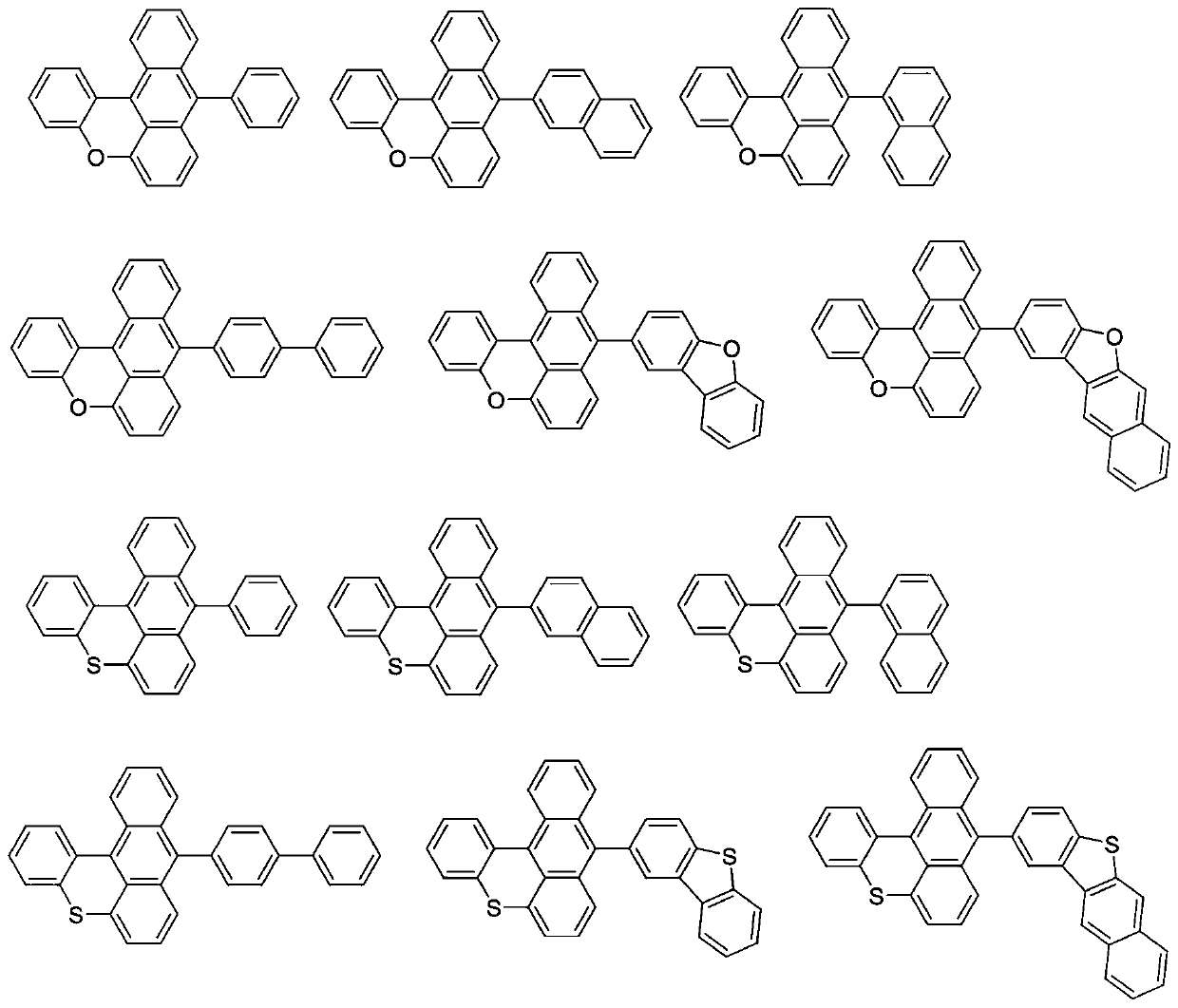

[0066] Embodiment 1: the synthesis of compound 1, the reaction formula of this synthesis is as follows:

[0067]

[0068] Add compound 1-1 (6.9g, 20mmol), phenylboronic acid (2.4g, 20mmol) and 2.00mol / L sodium carbonate (4.12g, 40mmol) solution into a three-necked flask, stir and dissolve with 100ml toluene, nitrogen protection, and then Add Pd(pph 3 ) 4 (1.13g, 1mmol), the reaction solution was stirred and refluxed for 12h, TLC and MS showed that the reaction was complete, mainly the target product, cooling, the reaction solution was washed three times with 150ml of saturated brine, dried over anhydrous sodium sulfate, and evaporated to remove The solvent was used to obtain a residue, and the residue was purified by column with DCM / PE (1:10) to obtain a white solid compound, namely compound 1.

Embodiment 2

[0069] Embodiment 2: the synthesis of compound 2, the reaction formula of this synthesis is as follows:

[0070]

[0071] Add compound 2-1 (6.9g, 20mmol), dinaphthylboronic acid (3.4g, 20mmol) and 2.00mol / L sodium carbonate (4.12g, 40mmol) solution into a three-necked flask, stir and dissolve with 100ml of toluene, nitrogen protection, Then add Pd(pph 3 ) 4 (1.13g, 1mmol), the reaction solution was stirred and refluxed for 12h, TLC and MS showed that the reaction was complete, mainly the target product, cooling, the reaction solution was washed three times with 150ml of saturated brine, dried over anhydrous sodium sulfate, and evaporated to remove The solvent and the residue were purified by column with DCM / PE (1:10) to obtain a white solid compound, namely compound 2.

Embodiment 3

[0072] Embodiment 3: the synthesis of compound 3, the reaction formula of this synthesis is as follows:

[0073]

[0074] Add compound 3-1 (6.9g, 20mmol), mononaphthaleneboronic acid (3.4g, 20mmol) and 2.00mol / L sodium carbonate (4.12g, 40mmol) solution into a three-necked flask, stir and dissolve with 100ml of toluene, nitrogen protection, Then add Pd(pph 3 ) 4 (1.13g, 1mmol), the reaction solution was stirred and refluxed for 12h, TLC and MS showed that the reaction was complete, mainly the target product, cooling, the reaction solution was washed three times with 150ml of saturated brine, dried over anhydrous sodium sulfate, and evaporated to remove The solvent and the residue were purified by column with DCM / PE (1:10) to obtain a white solid compound, namely compound 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap