Corrosion liquid and corrosion method for identifying twin crystals on surface of indium phosphide

A technology of etching solution and indium phosphide, which is applied in chemical instruments and methods, preparation of test samples, single crystal growth, etc., can solve problems such as difficult control, inability to identify wafer twins, fast corrosion of indium phosphide, etc. Achieve the effects of easy identification, controllable corrosion speed and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

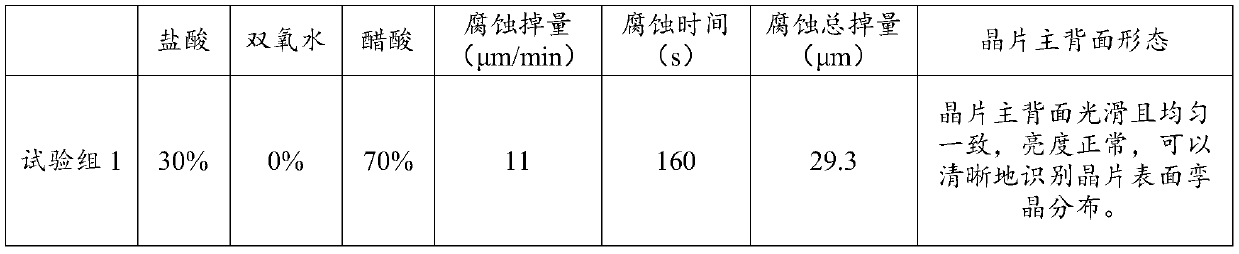

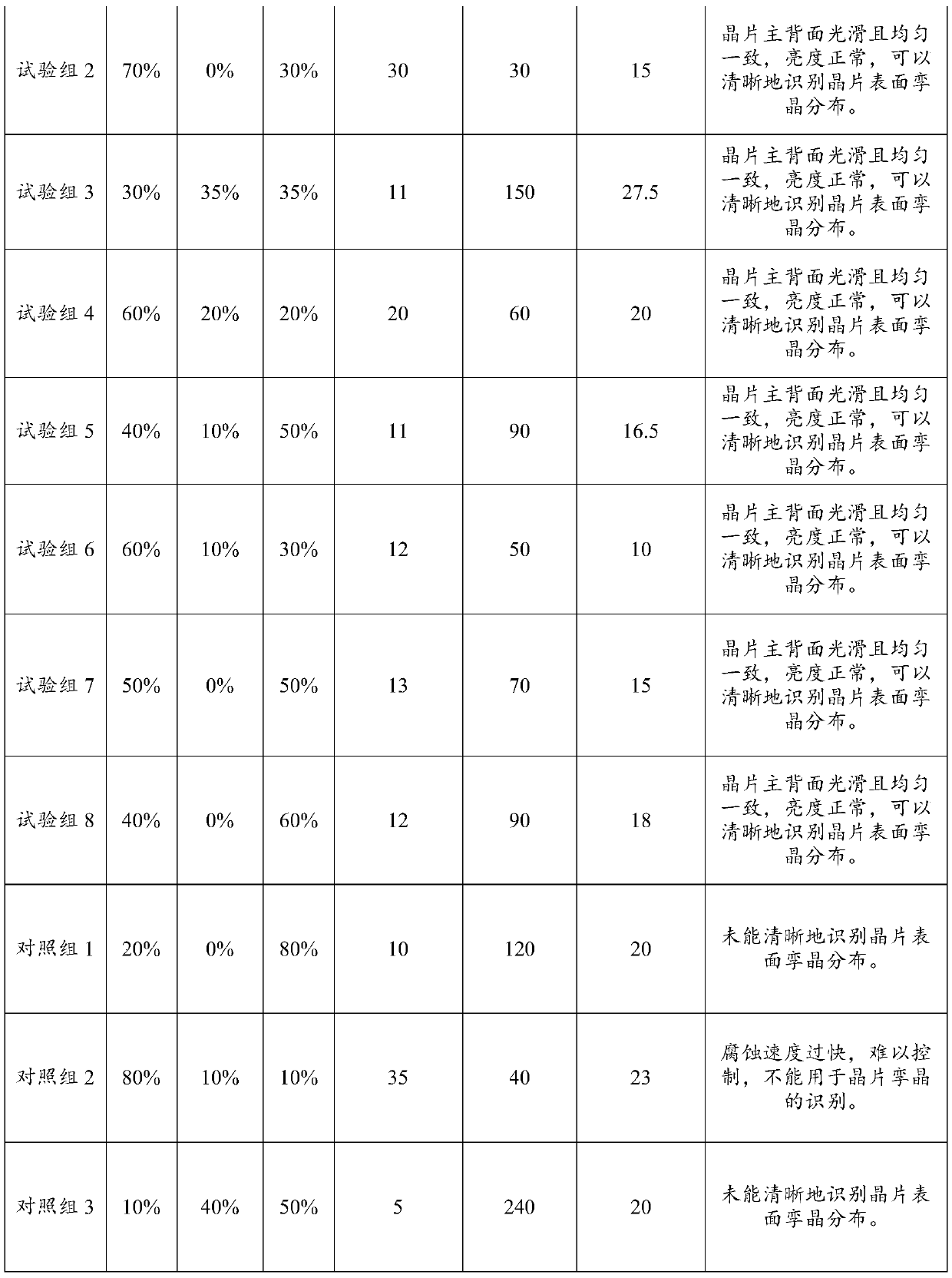

Embodiment 1

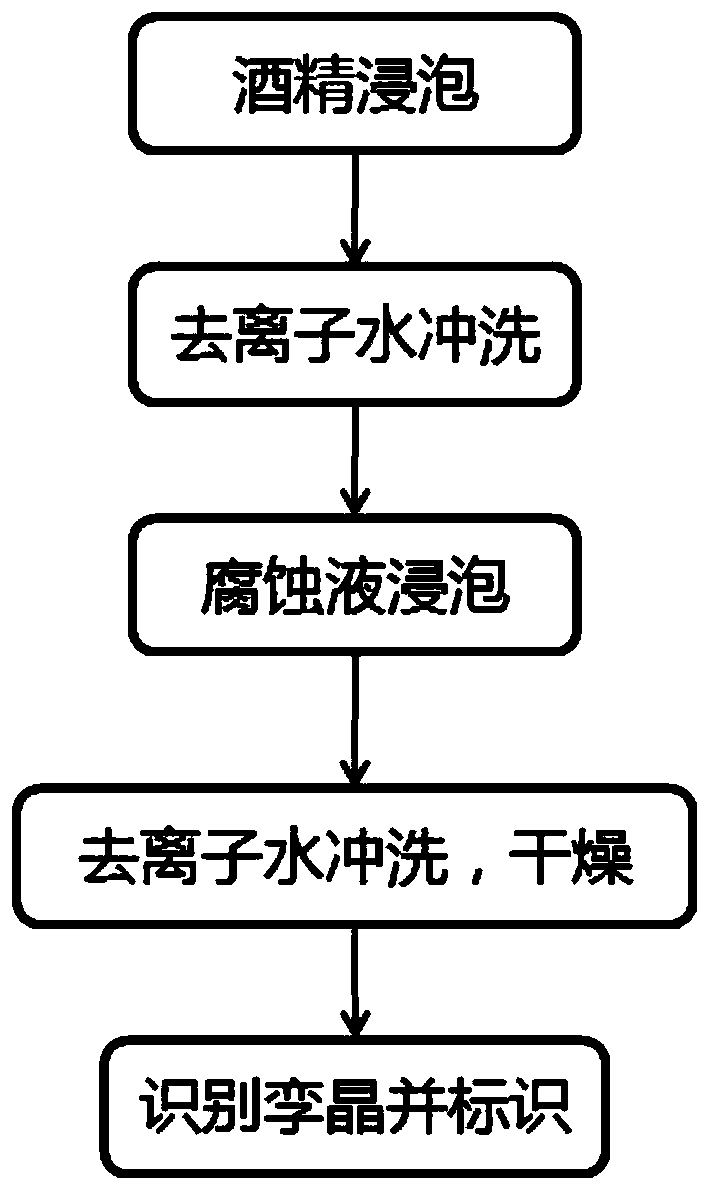

[0028] The flow chart of the etching method for the identification of twins on the surface of indium phosphide in this embodiment is as follows figure 1 shown.

[0029] Five pieces of 4-inch indium phosphide (InP) wafers with a thickness of 450-460 μm were sliced and placed in a wafer box (Cassette), and the Cassette with the wafers was placed in 80% alcohol by mass fraction and soaked at 10°C for 20 minutes ;Place the Cassette with the wafer in the overflow tank, rinse it with deionized water overflow rinse and quick flushing water for 30s, and then add manual flushing for 30s; then immerse the Cassette with the wafer into the volume ratio In a solution of 30% hydrochloric acid, 50% acetic acid and 20% hydrogen peroxide, the hydrochloric acid is hydrochloric acid with a mass fraction of 36% to 38%, the hydrogen peroxide is hydrogen peroxide with a mass fraction of 30% to 32%, and the acetic acid is a mass fraction of 99.7% to 100% % acetic acid, shake at a constant speed f...

Embodiment 2

[0032] 5 pieces of 4-inch indium phosphide (InP) wafers with a thickness of 460-470 μm were sliced and put into a wafer box (Cassette), and the Cassette with the wafers was placed in 98% alcohol by mass fraction and soaked at 40°C for 30 minutes; Place the Cassette with the wafer in the overflow tank, rinse it with deionized water overflow rinse and quick flushing water for 120s, and then add manual flushing for 30s; then immerse the Cassette with the wafer in a volume ratio of In a solution of 70% hydrochloric acid, 20% acetic acid, and 10% hydrogen peroxide, wherein hydrochloric acid is hydrochloric acid with a mass fraction of 36% to 38%, hydrogen peroxide is hydrogen peroxide with a mass fraction of 30% to 32%, and acetic acid is a mass fraction of 99.7% to 100%. Shake at a constant speed for 30s at the temperature of the etching solution at 40°C; then immediately place the Cassette with the wafer in the overflow tank and rinse it for 90s by combining overflow rinsing wit...

Embodiment 3

[0035] 5 pieces of 4-inch indium phosphide (InP) wafers with a thickness of 440-450 μm were sliced and put into a wafer box (Cassette), and the Cassette with the wafers was placed in 98% alcohol by mass fraction and soaked at 20°C for 30 minutes; Place the Cassette with the wafer in the overflow tank, rinse it with deionized water overflow rinse and quick flushing water for 70s, and then add manual flushing for 30s; then immerse the Cassette with the wafer at a volume ratio of In a solution of 30% hydrochloric acid and 70% acetic acid, wherein hydrochloric acid is hydrochloric acid with a mass fraction of 36% to 38%, and acetic acid is acetic acid with a mass fraction of 99.7% to 100%, shake at a constant speed for 90s at the temperature of the corrosion solution at 20°C; then immediately Place the Cassette with the wafer in the overflow tank, rinse it with a combination of deionized water overflow rinse and quick flushing water for 80s, and then manually flush it for 30s; so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com