Device and method for on-line automatic thickness detection of rubber and plastic coiled material

A technology for automatic detection and coiling, which is applied in the field of automatic thickness detection of rubber and plastic coils, and devices for online automatic thickness detection of rubber and plastic coils, to achieve the effects of non-destructive detection, high data accuracy, and avoidance of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

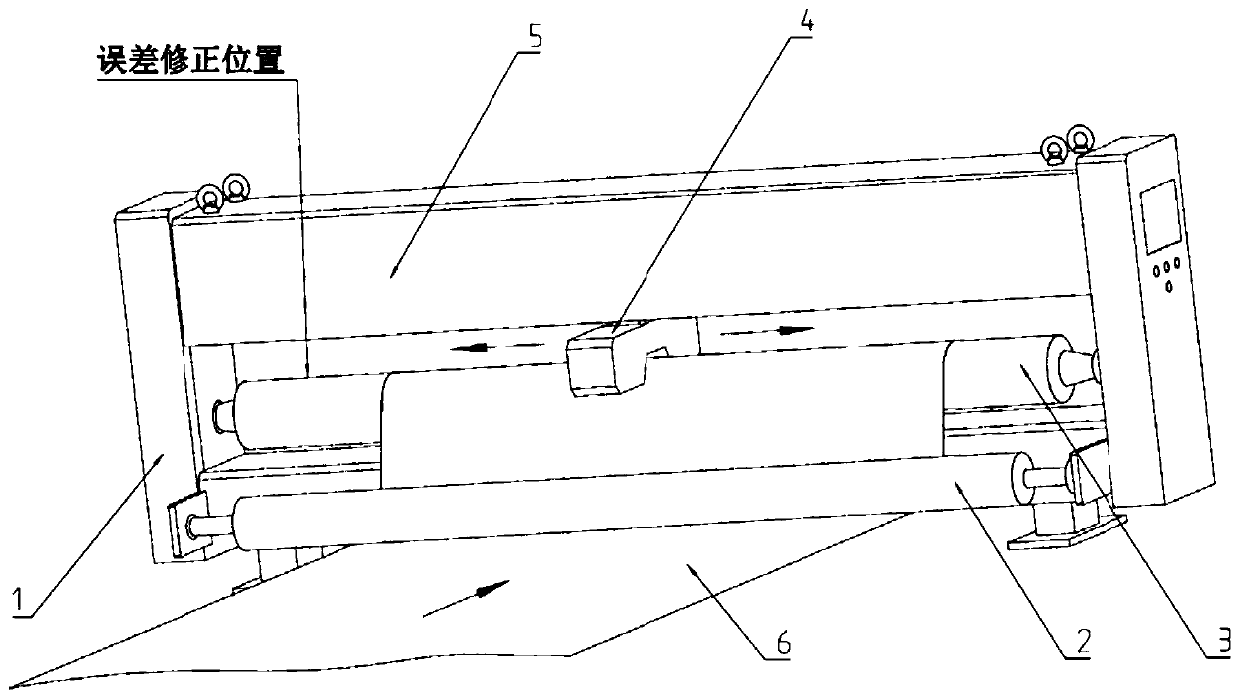

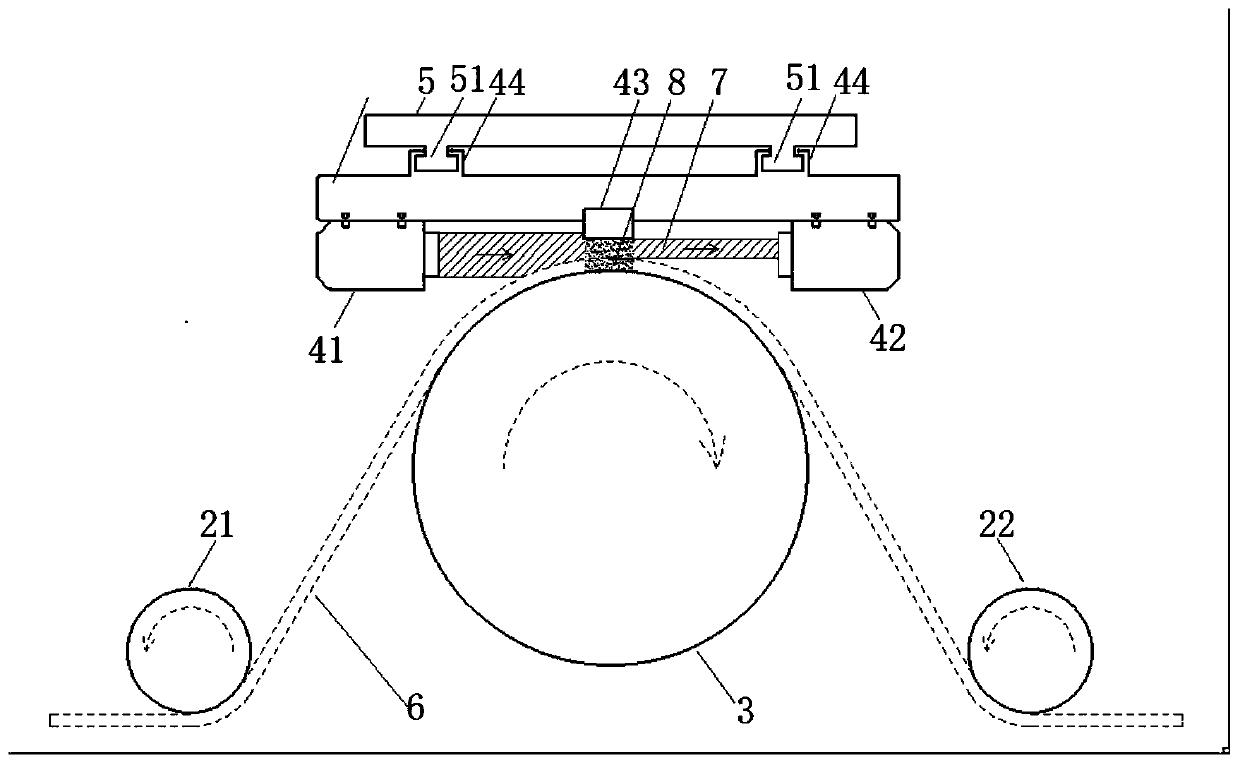

[0044] Such as figure 1 as shown, figure 2 As shown, the device for automatically detecting the thickness of rubber and plastic coils online includes a base 1, and also includes a guide roller 2 arranged on the base 1, a reference roller 3 and a beam 5, and a sliding fixed plate 4 arranged on the beam 5; wherein, The sliding fixed plate 4 is slidably connected with the beam 5;

[0045] There is a groove on the sliding fixing plate 4, and the reference roller 3 is arranged directly below the groove; a light source 41 is horizontally arranged on the inner side of the groove, and an image is horizontally arranged on the surface opposite to the light source 41 sensor 42;

[0046] An eddy current sensor 43 is arranged on the groove, and the eddy current sensor 43 is located directly above the reference roller 3; the bottom surface of the probe of the eddy current sensor 43 is arranged facing the reference roller 3;

[0047] The bottom surface of the probe of the eddy current se...

Embodiment 2

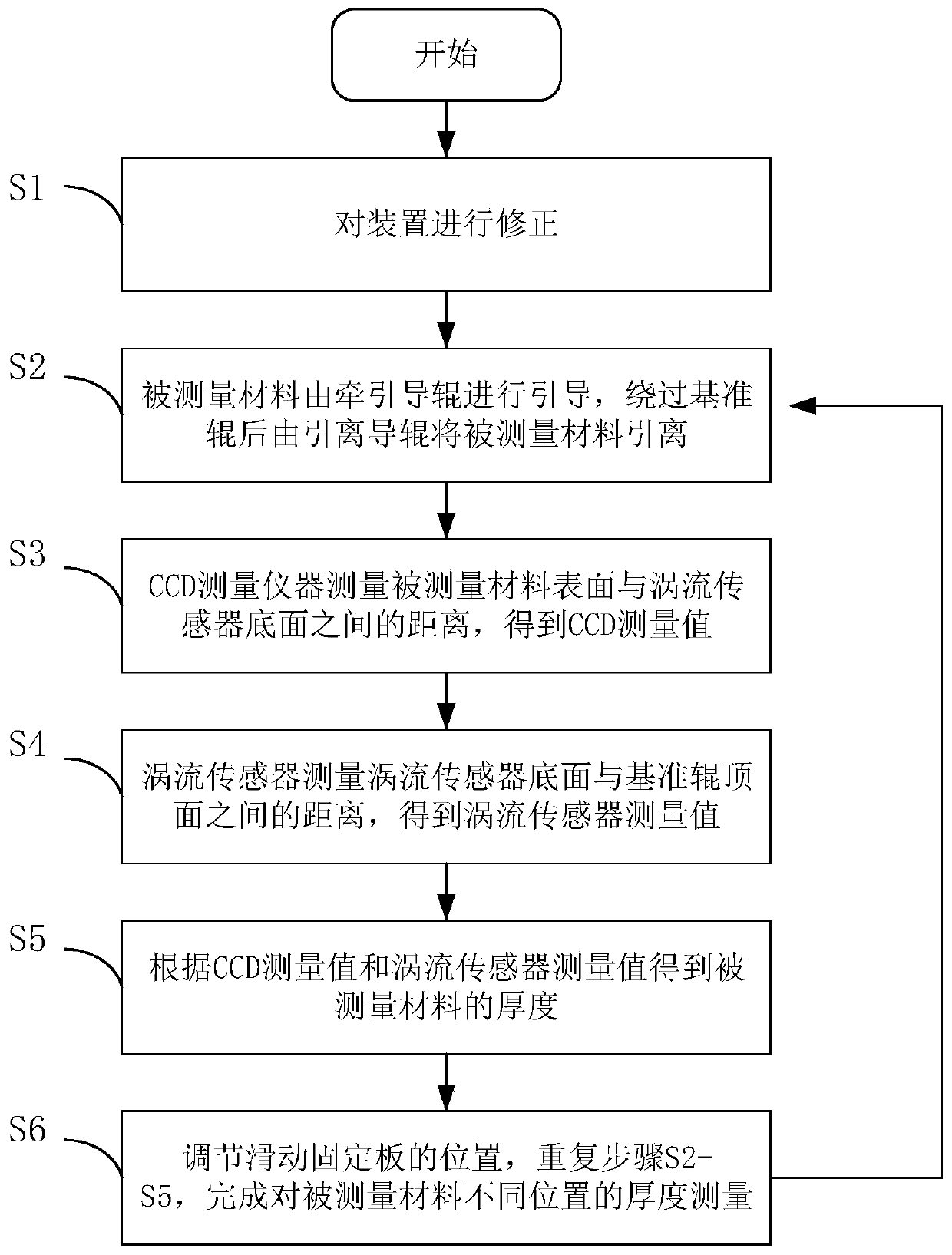

[0059] More specifically, on the basis of Example 1, such as image 3 As shown, the method for online automatic detection of thickness of rubber and plastic coils comprises the following steps:

[0060] S1: Correct the device;

[0061] S2: The material 6 to be measured is guided by the traction guide roller 21, and the material 6 to be measured is drawn away by the guide roller 22 after bypassing the reference roller 3;

[0062] S3: The CCD measuring instrument measures the distance between the surface of the material to be measured and the bottom surface of the eddy current sensor 43, and obtains a CCD measurement value of 7;

[0063] S4: the eddy current sensor 43 measures the distance between the bottom surface of the eddy current sensor 43 and the top surface of the reference roller 3, and obtains the measured value 8 of the eddy current sensor;

[0064] S5: Obtain the thickness of the measured material 6 according to the measured value 7 of the CCD and the measured valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com