Grain storage method of tall and flat warehouse

A tall, warehouse technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of less moving times of the loader, less workload of leveling the grain surface, and large loading capacity of the loader.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

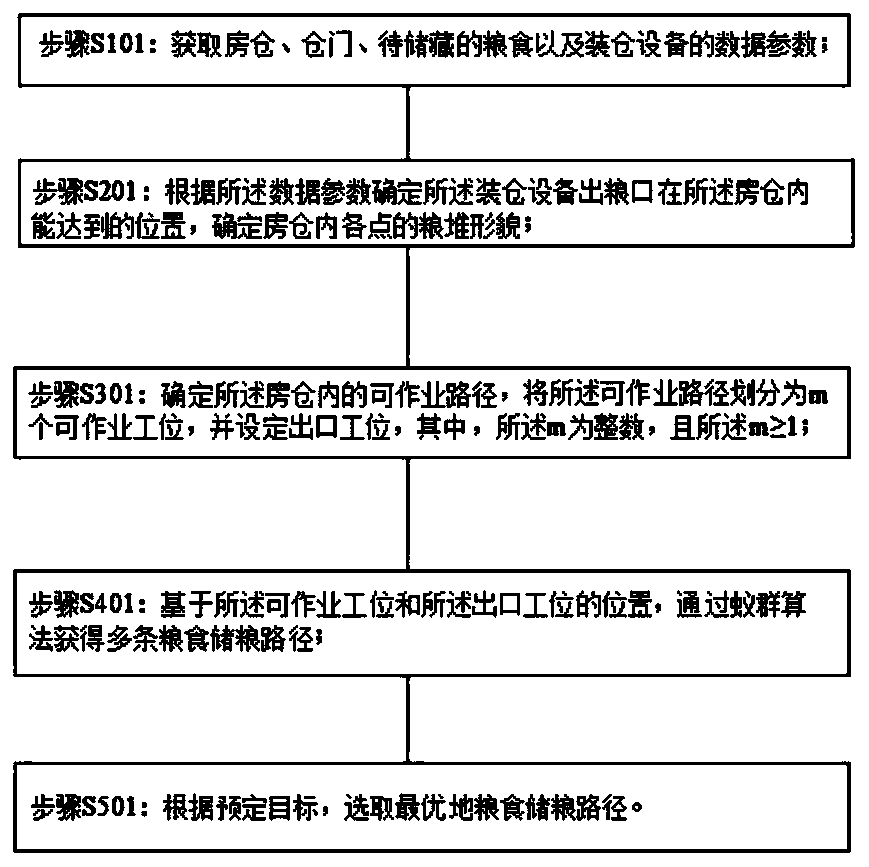

[0045] Embodiments of the present invention provide a method for storing grain in a tall flat room, such as figure 1 As shown, the method includes:

[0046] Step S101: Obtain the data parameters of the warehouse, warehouse door, grain to be stored and storage equipment;

[0047] Here, the data parameters for obtaining the warehouse include: length of the warehouse, width of the warehouse, and height of grain stacked in the warehouse.

[0048] The data parameters for obtaining the warehouse door include: door center position, door width, door height, and sealing plate height (when grain is stacked at the warehouse door, a sealing plate needs to be installed).

[0049] The data parameters for obtaining the grain to be stored include: the type of grain, the bulk density, and the gravity angle of the grain when stacking the grain.

[0050] The data parameters of the silo loading equipment include: forearm length, maximum telescopic length, slewing height, maximum grain throwing ...

Embodiment 2

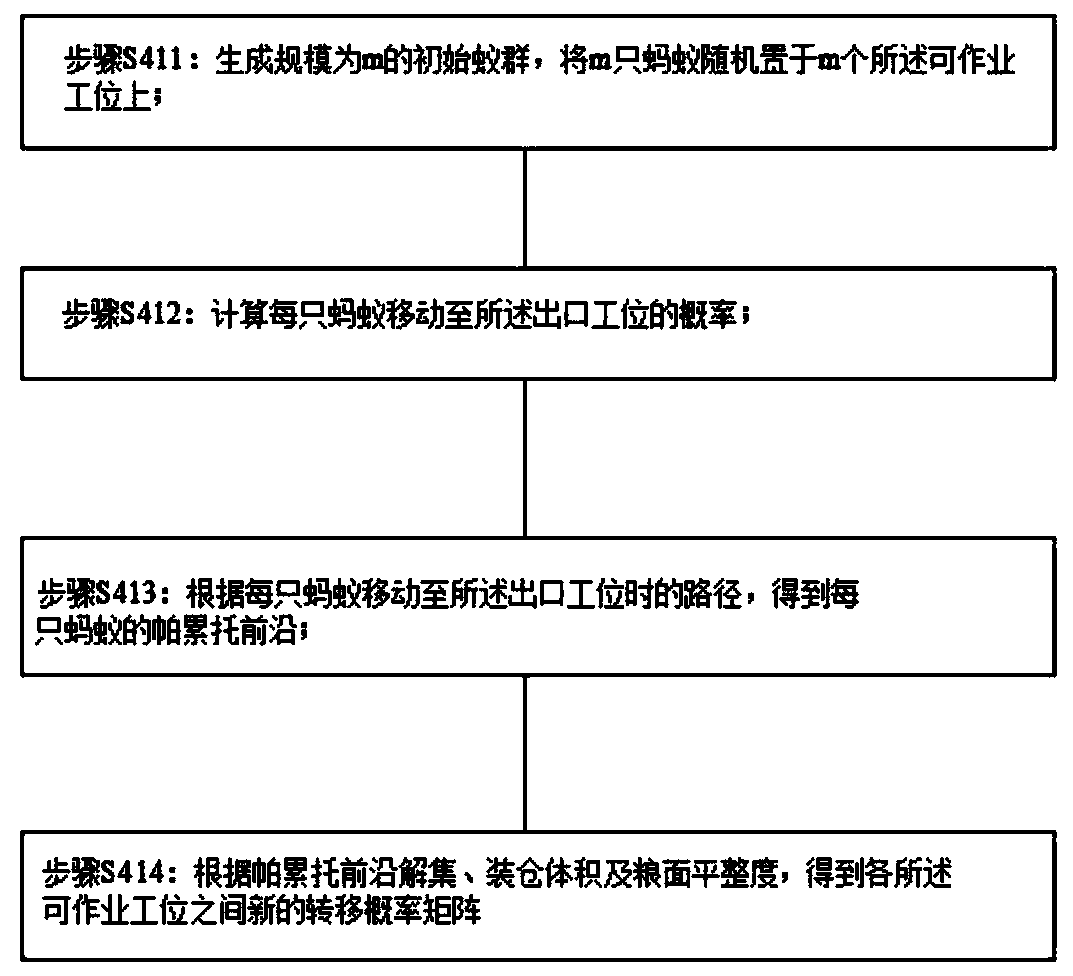

[0061] Further, in the embodiment of the present invention, as figure 2 As shown, the method for obtaining multiple grain storage paths through the ant colony algorithm based on the positions of the workable station and the export station is:

[0062] Step S411: Generate an initial ant colony with a size of m, and randomly place m ants on the m operable workstations;

[0063] Step S412: Calculate the probability of each ant moving to the exit station;

[0064] Here, the formula for calculating the probability of each ant moving to the exit station is:

[0065]

[0066] Wherein, the i represents the starting point, the j represents the end point, and the k represents a node between the starting point and the end point;

[0067] The η ij =1 / d ij Visibility is the reciprocal of the distance between two points i and j;

[0068] The τ ij (t) is the pheromone intensity from i to j at time t;

[0069] The allowed k A collection of nodes that have not been visited;

[007...

Embodiment 3

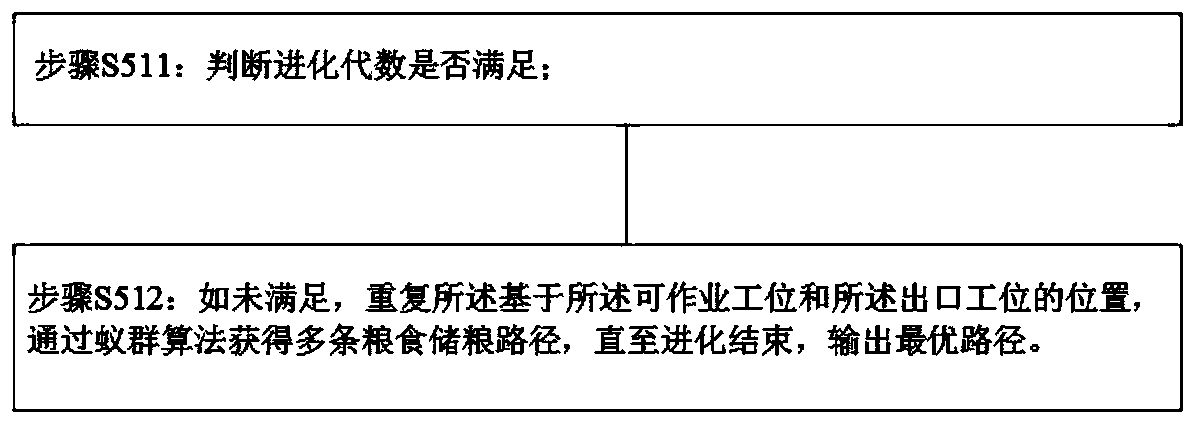

[0103] Further, as image 3 As shown, in the embodiment of the present invention, the method of selecting the optimal grain storage path according to the predetermined target is:

[0104] Step S511: Determine whether the evolution algebra is satisfied, wherein the evolution algebra refers to the number of algorithm iterations;

[0105] Step S512: If not satisfied, repeat the steps based on the positions of the workable station and the exit station, and obtain multiple grain storage paths through the ant colony algorithm until the evolution is complete, and output the optimal path.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap