Paint spraying equipment

A technology of spraying equipment and paint, applied in the direction of spraying device, liquid spraying device, etc., can solve problems such as affecting the use experience, and achieve the effect of improving feeding experience, improving work efficiency, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

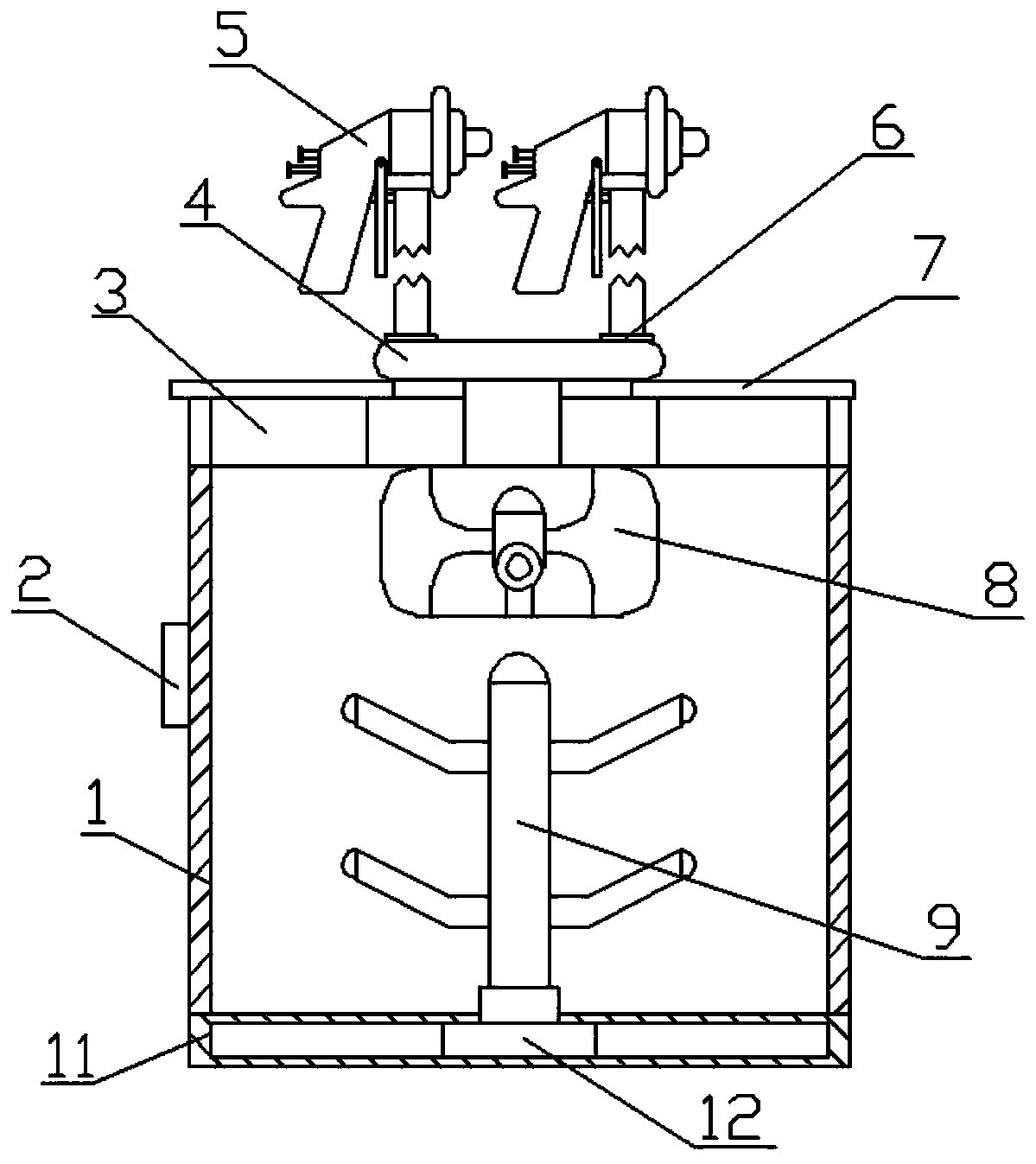

[0022] As attached figure 1 Attached image 3 Shown

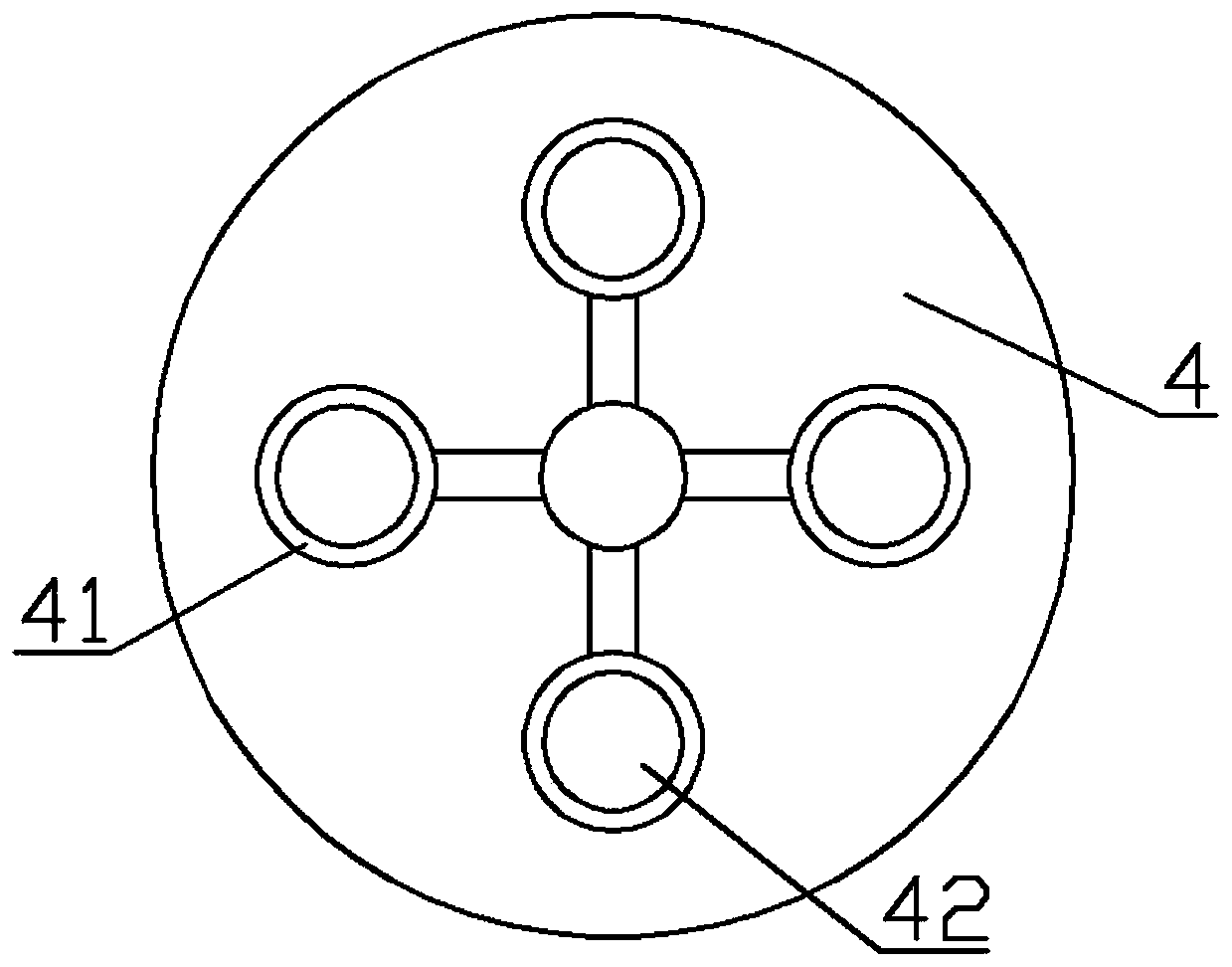

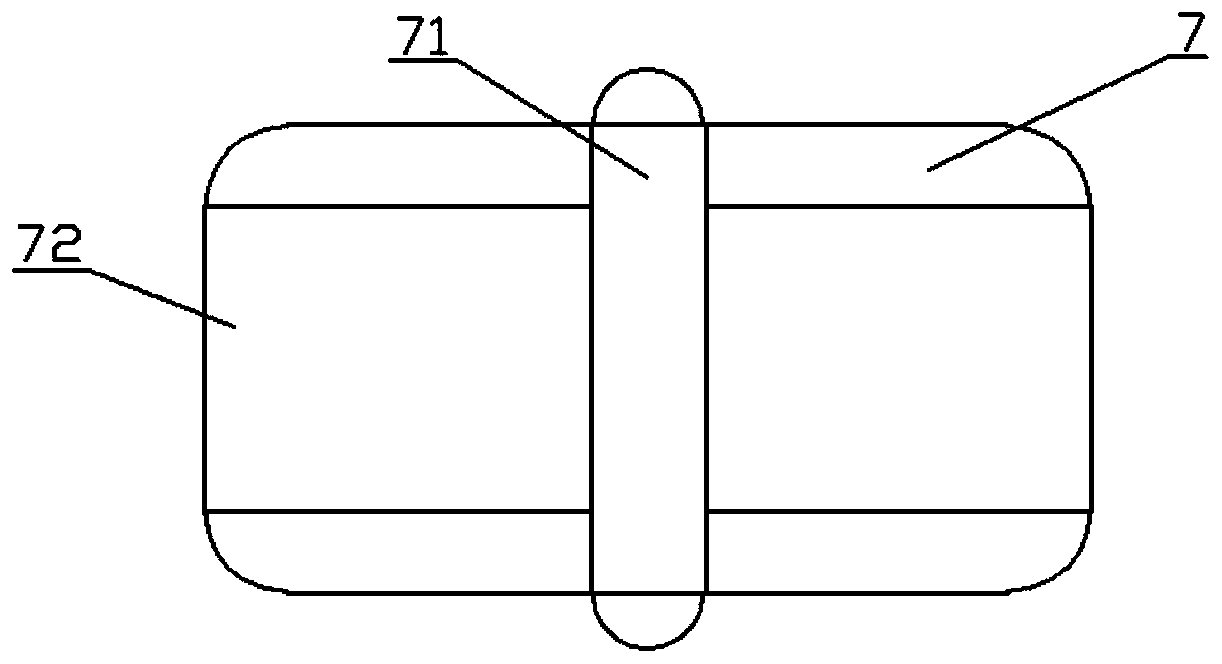

[0023] The present invention provides a paint spraying equipment, including a paint box 1, a switch 2, a feed port 3, a splitter 4, a spray gun 5, a seal 6, a cover 7, a self-priming pump 8 and a stirring column 9, the paint box A switch 2 is installed on the surface side of the paint box 1, and a stirring column 9 is installed inside the paint box 1, and a self-priming pump 8 is arranged above the stirring column 9; both sides of the upper end of the paint box 1 are provided with feed ports 3, and a cover 7 is installed on the surface of the feed port 3, the upper end of the feed port 3 is provided with a splitter 4, wherein the surface of the splitter 4 is connected with a spray gun 5 through a seal 6; the paint box 1 includes a The electric box 11 and the motor 12, and the bottom end of the paint box 1 is provided with a power distribution box 11, and the inside of the power distribution box 11 is provided with a motor 12;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com