Power-off switching hammer drill tool

A switch-type, hammer-drilling technology, applied in the field of hammer-drilling tools, can solve the problems of meshing teeth and meshing teeth wear, affecting the normal operation of the equipment, and the possibility of accidents, reducing collision and wear, and the switching process is convenient and fast. The effect of reducing the sense of stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, innovative features and functions realized by the present invention easy to understand, the present invention will be further described below.

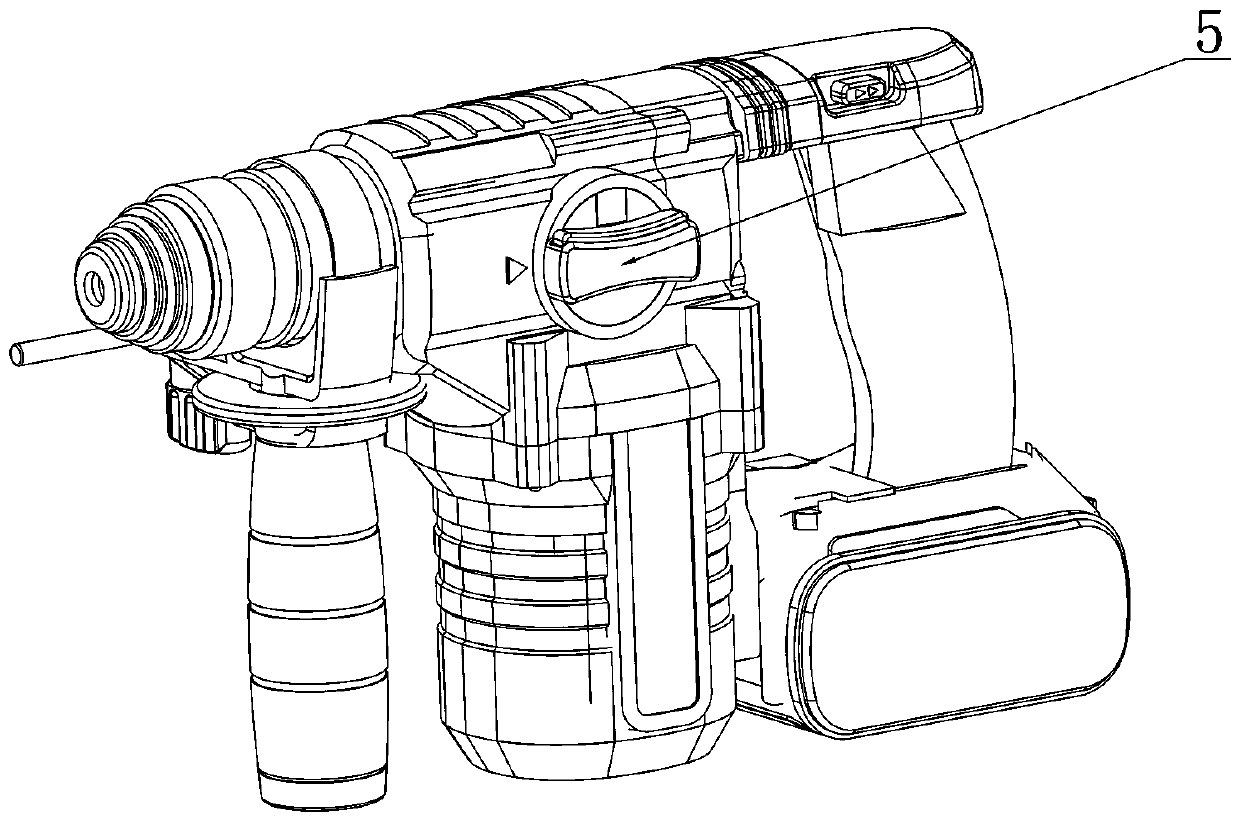

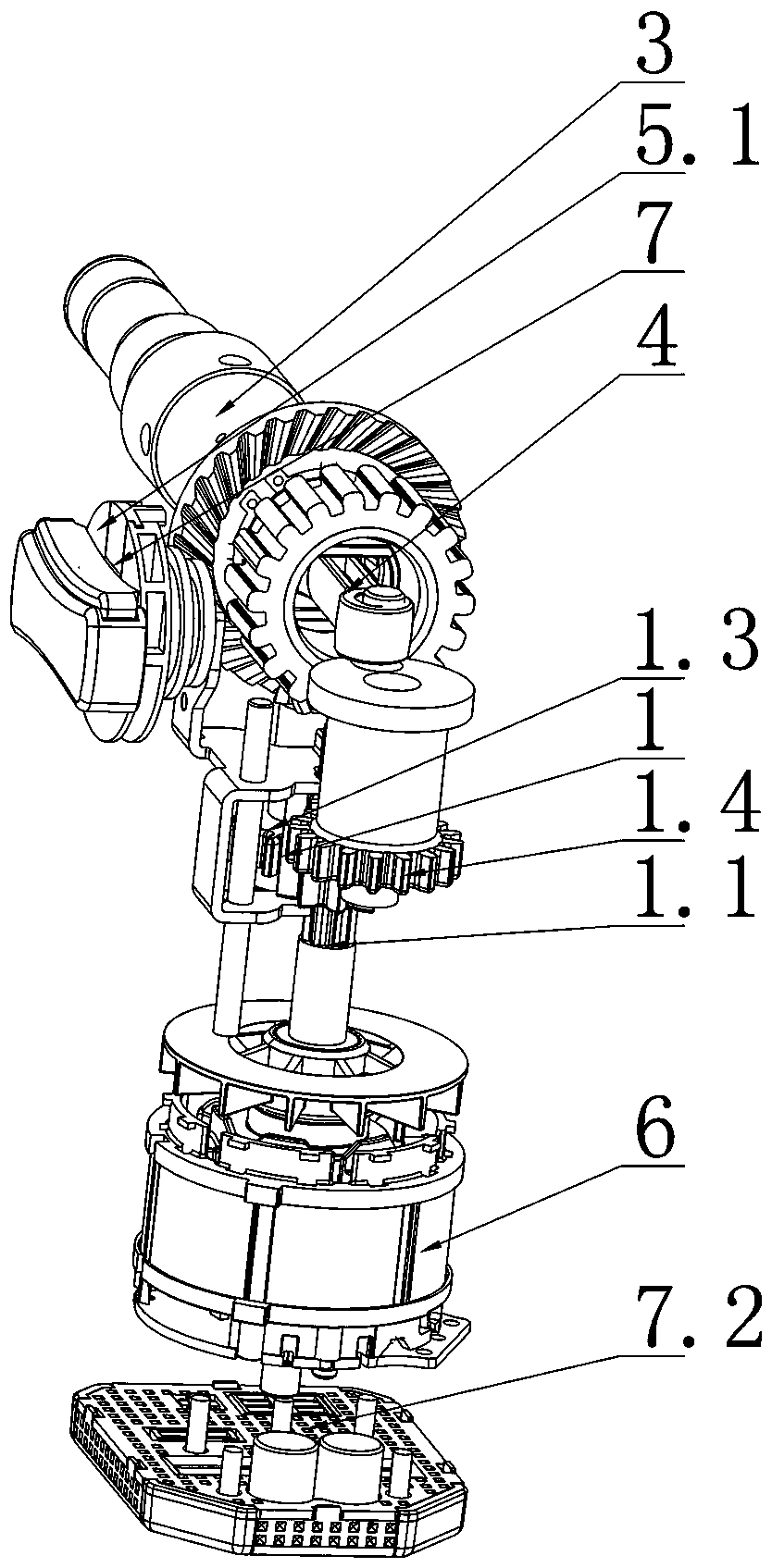

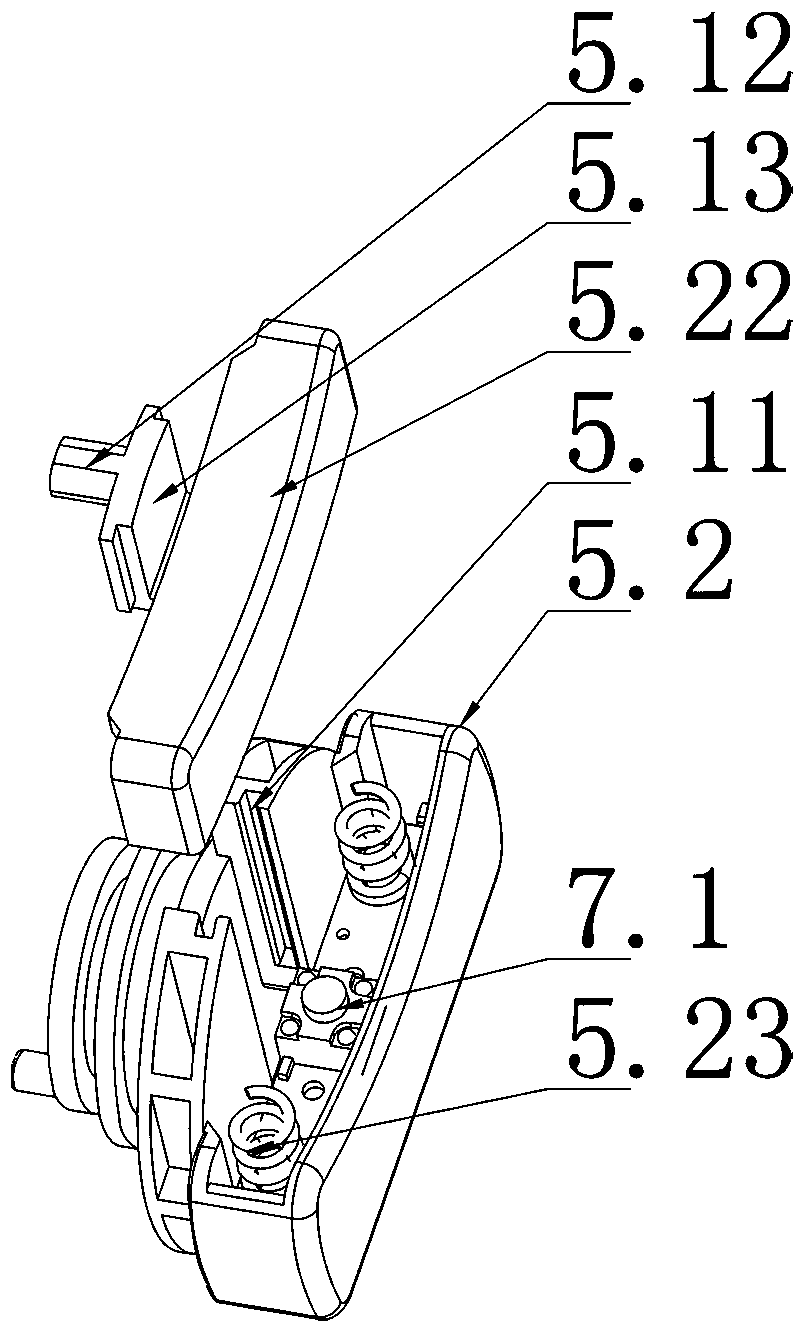

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the technical solution of the power-off switchable hammer drill tool of the present invention includes a casing, a drilling assembly 3 and a hammering assembly 4 matched with the casing, a driving motor 6, a controller 7.2 for controlling the driving motor 6, a transmission mechanism 1, The shifting assembly 5 provided on the casing, the shifting assembly 5 includes a shifting base 5.1 that is rotatable relative to the casing, and a hollow shifting knob 5.2 fixedly connected to the shifting base 5.1. By operating the hollow shifting knob 5.2 Rotate the shift base 5.1, the shift base 5.1 realizes the shifting of the transmission mechanism 1 through the transmission of the transmission member, the shift ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com