Rotating guiding wheel set guiding type track robot base plate

An orbital robot and guided technology, applied in the field of orbital robots, can solve problems such as difficult disassembly, large turning radius, and inconvenient maintenance, and achieve the effects of easy maintenance, reduced resistance, and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

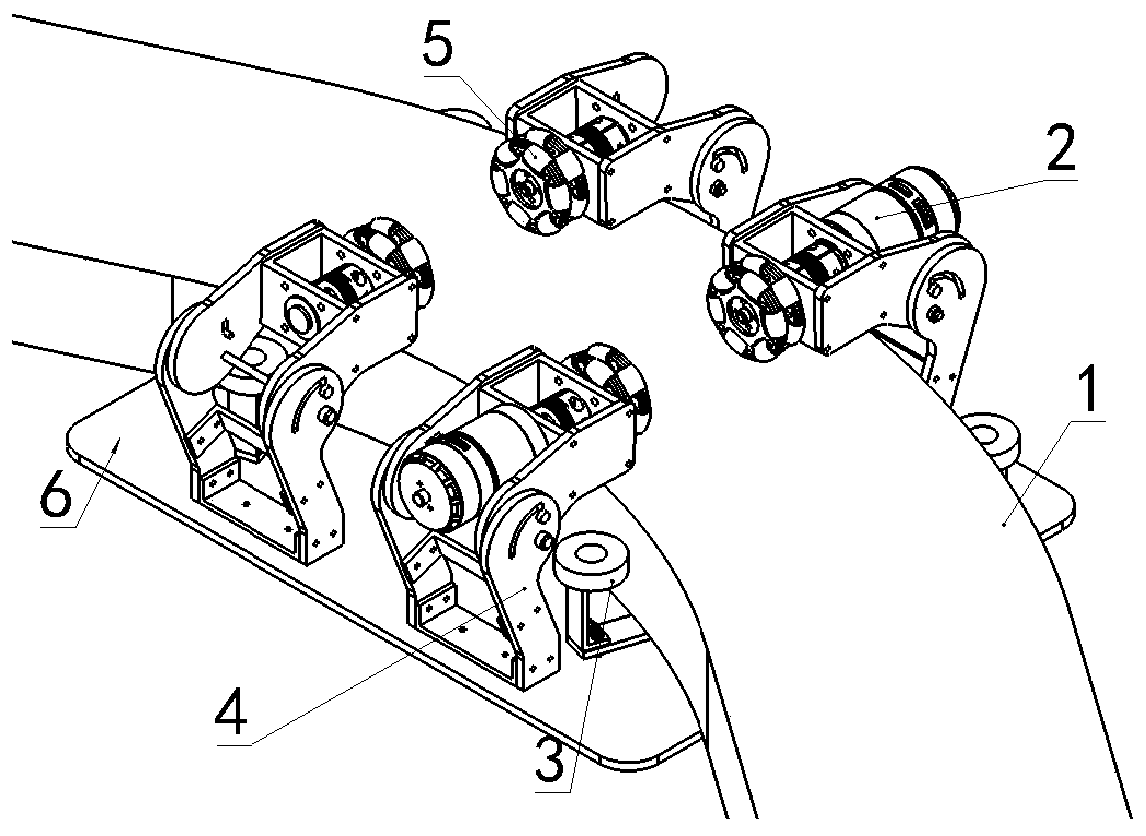

[0044] Such as figure 1 As shown, the track 1 involved in the present invention is a track with a rectangular cross-section, and there are supporting columns at both ends and a reinforcing crossbeam above to prevent the track from being deformed and bent. The overall track is "S" shaped with a small turning radius.

[0045] Such as figure 1 As shown, a rotatable guide wheel group guided track robot chassis, including:

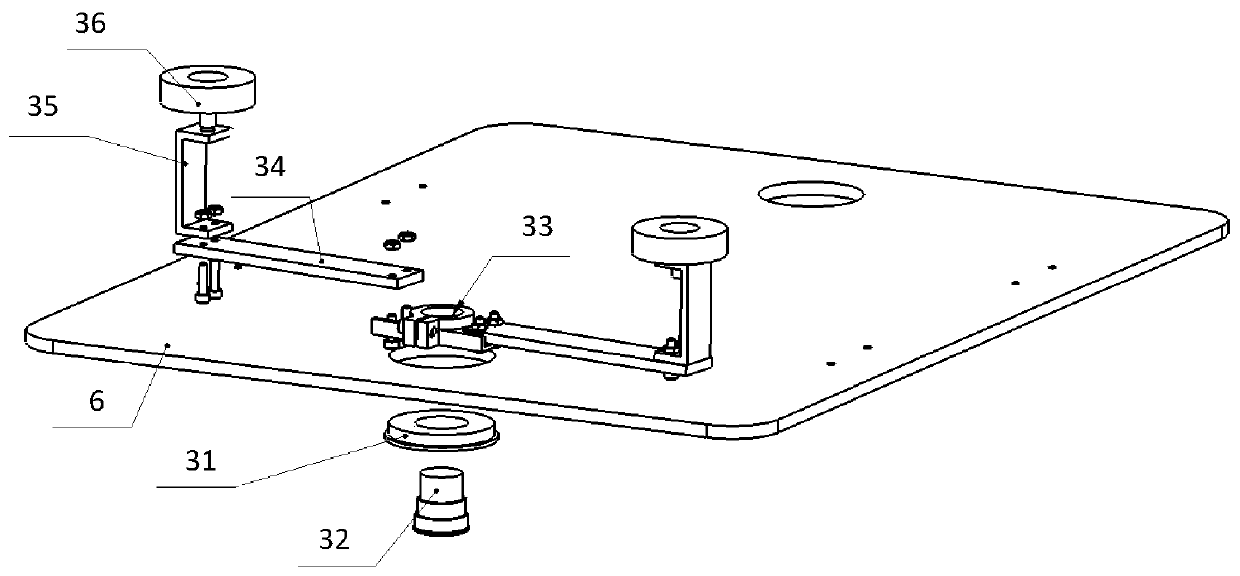

[0046] Chassis main body 6;

[0047] Four sets of quick-release mounting mechanisms 4 are arranged oppositely in pairs on the left and right sides of the chassis main body 6, and each quick-release mounting mechanism 4 maintains rolling contact with or separates from the upper surface of the rail 1 by changing the elevation angle of the front end ;

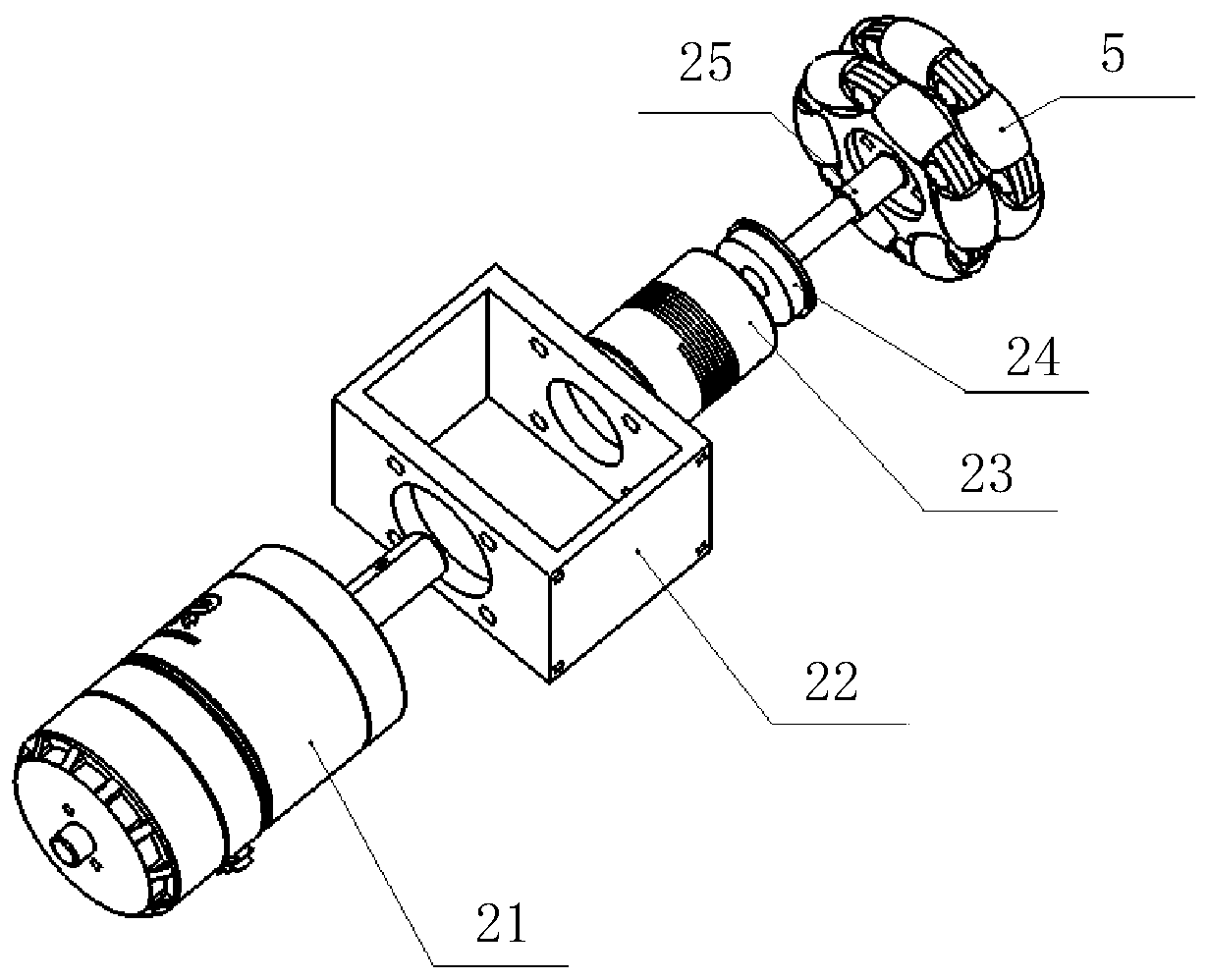

[0048] At least two driving mechanisms 2 are drivingly connected to two q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com