Automobile heat pump air conditioner adopting patch type micro-channel heat exchanger

A heat pump air conditioner and heat exchanger technology, which is applied to vehicle parts, heat exchange equipment, air treatment equipment, etc., can solve the problems of heavy copper tube aluminum fins and unfavorable weight loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

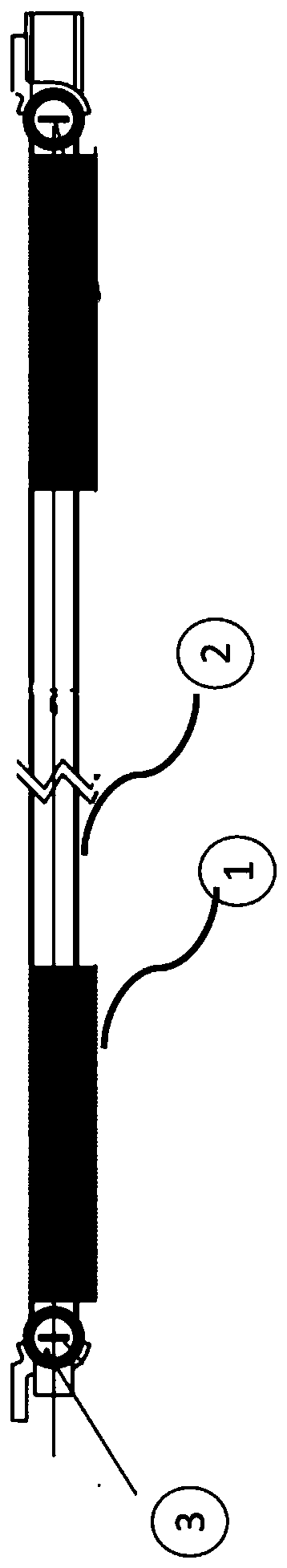

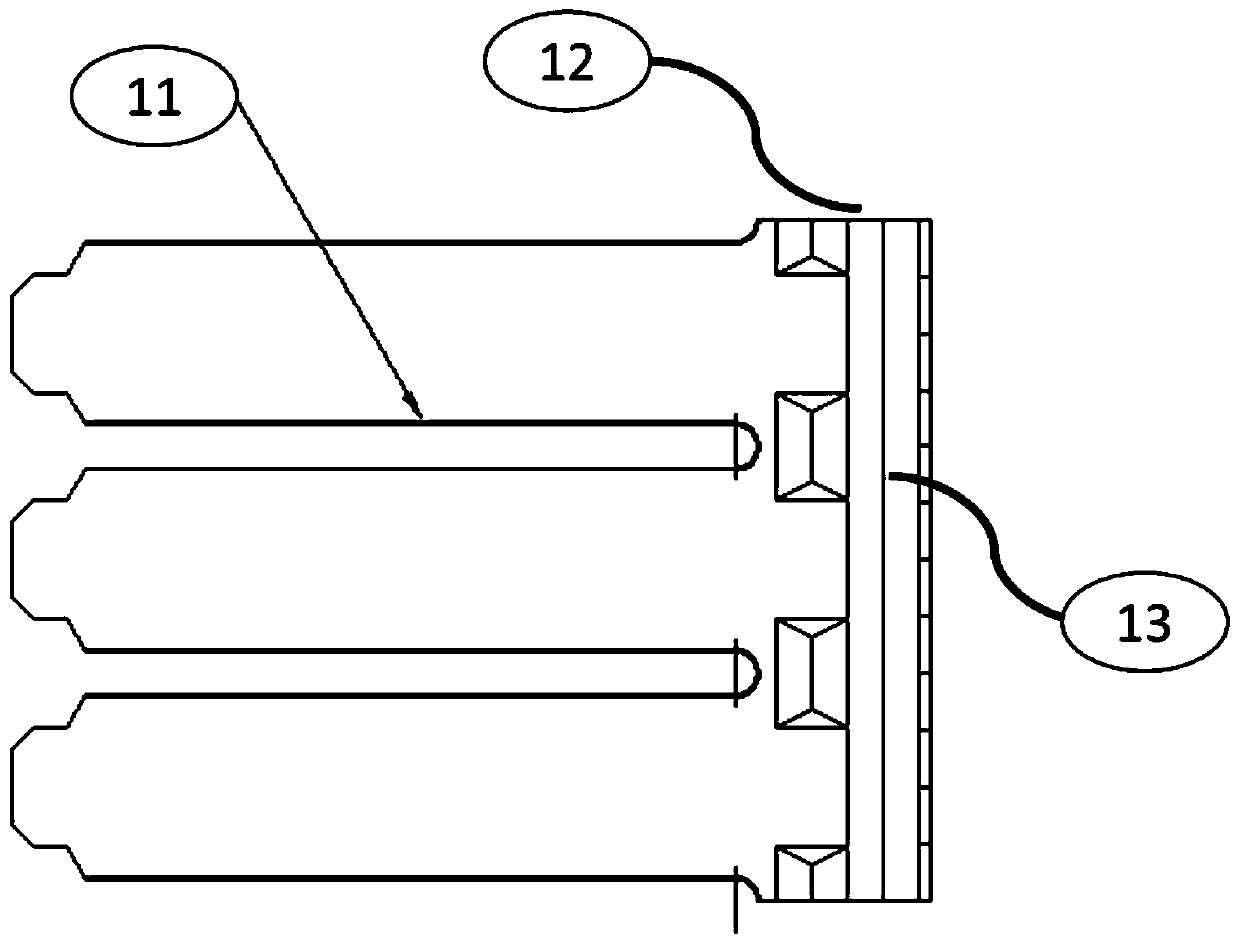

[0016] Such as figure 1 and figure 2 As shown, a kind of automobile heat pump air conditioner adopting the insert type microchannel heat exchanger of the present invention includes the insert type microchannel heat exchanger, and the insert type microchannel heat exchanger includes flat tubes 2 and fins 1, and the Both ends of the flat tube 2 are provided with headers 3 , and the fin 1 is provided with a flat tube groove 11 , and the flat tube 2 is inserted into the flat tube groove 11 of the fin 1 .

[0017] Such as figure 2 As shown, the flat tubes 2 of this embodiment are arranged horizontally, and the fins 1 are arranged vertically. A wing 12 is provided on one side of the flat tube groove 11 on the fin 1 , and the width of the wing 12 is 1 / 5-1 / 3 of the width of the flat tube 2 . In addition, in order to conduct water better when it rains, the wing edge 12 is provided with a water guide line 13, so that the water flow will not flow to core components such as flat tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com