Tension control method and device for scraper conveyor

A technology of scraper conveyor and control method, which is applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., and can solve problems such as chain fatigue, easy chain jamming, and damaged sprockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

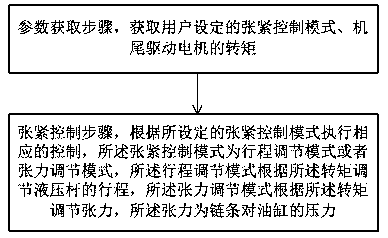

[0036] Embodiment 1. This embodiment proposes a tension control method for scraper conveyors, such as figure 1 shown, including the following steps:

[0037] The parameter acquisition step is to acquire the tension control mode set by the user and the torque of the tail drive motor;

[0038] The tension control step is to perform corresponding control according to the set tension control mode, wherein the tension control mode is a stroke adjustment mode or a tension adjustment mode, the stroke adjustment mode is to adjust the stroke of the hydraulic cylinder according to the torque, and the tension adjustment mode The tension is adjusted according to the torque, and the tension is the pulling force of the oil cylinder on the chain, which reflects the tension force of the tensioning oil cylinder on the chain. This control method is adjusted through torque. Because different stages and conveyor loads are different, it specifically reflects the difference in torque. Therefore, i...

Embodiment 2

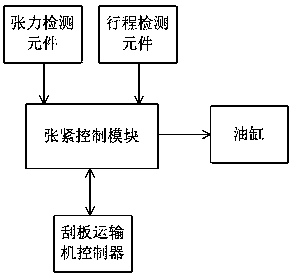

[0060] Embodiment 2, this embodiment proposes a scraper conveyor tension control device, such as figure 2 shown, including:

[0061] The tension detection element is arranged on the tail hydraulic oil cylinder and is used to detect the pressure of the chain on the oil cylinder;

[0062] A stroke detection element, which is arranged on the tail hydraulic cylinder, is used to detect the stroke of the hydraulic cylinder;

[0063] The tension control module is connected to the controller of the scraper conveyor through the can bus, and is used to receive the parameters sent by the controller of the scraper conveyor, and execute the tension control step, which is mainly used to control the stroke of the tension cylinder or tension;

[0064] The parameters sent by the scraper conveyor controller include at least: the tension control signal, the torque of the tail drive motor, and the torque of the tail drive motor can also be replaced by the torque percentage of the tail drive mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com