Automobile brake fluid draining device

A technology in automobile brakes and devices, which is applied in the direction of distribution devices, liquid distribution, conveying or transfer devices, special distribution devices, etc., and can solve the problem of insufficient replacement of waste liquid, insufficient discharge of liquid, and inconvenient use of the discharge device and other problems, to prevent incomplete liquid replacement, increase the range of liquid absorption, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

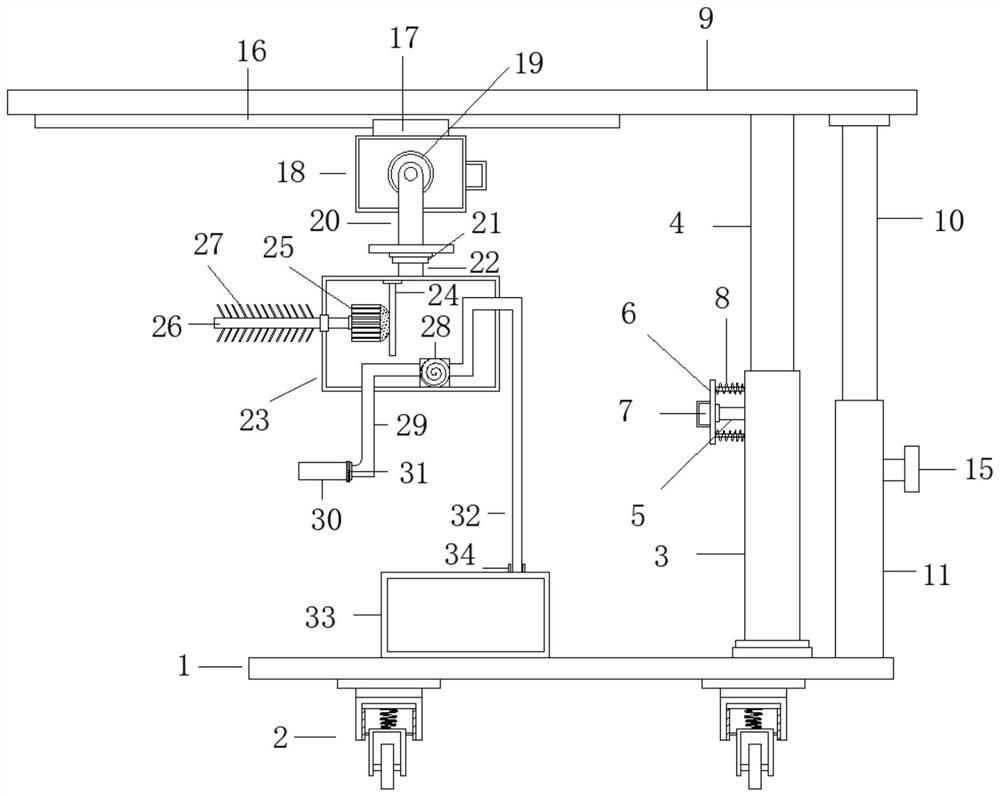

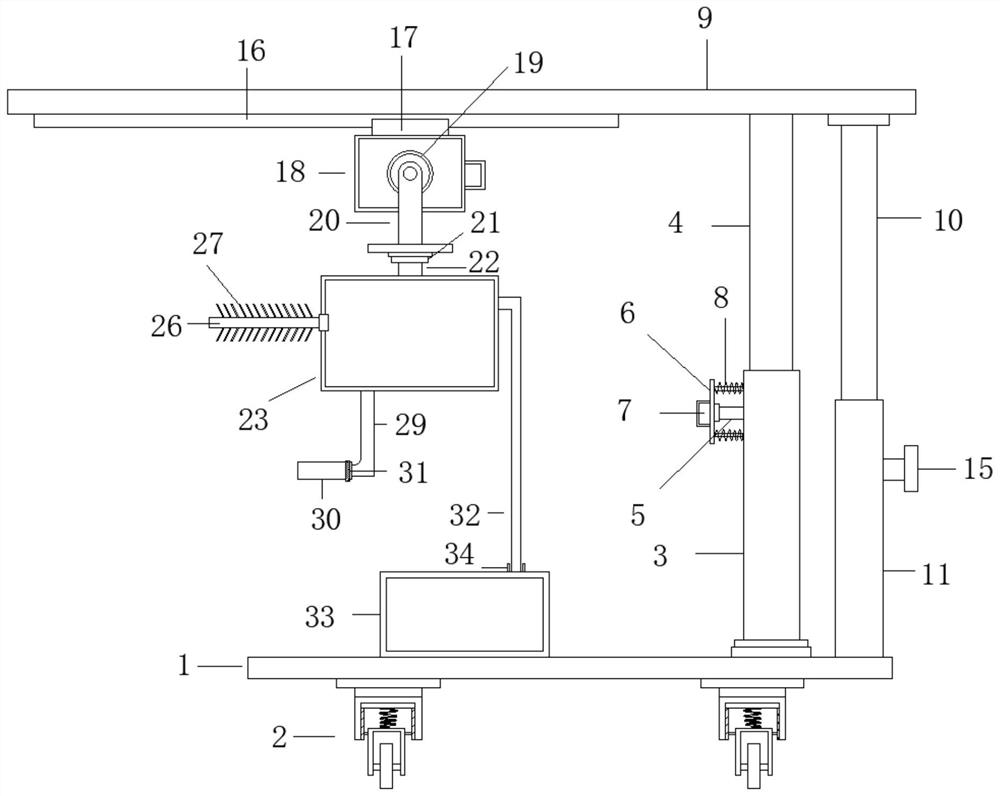

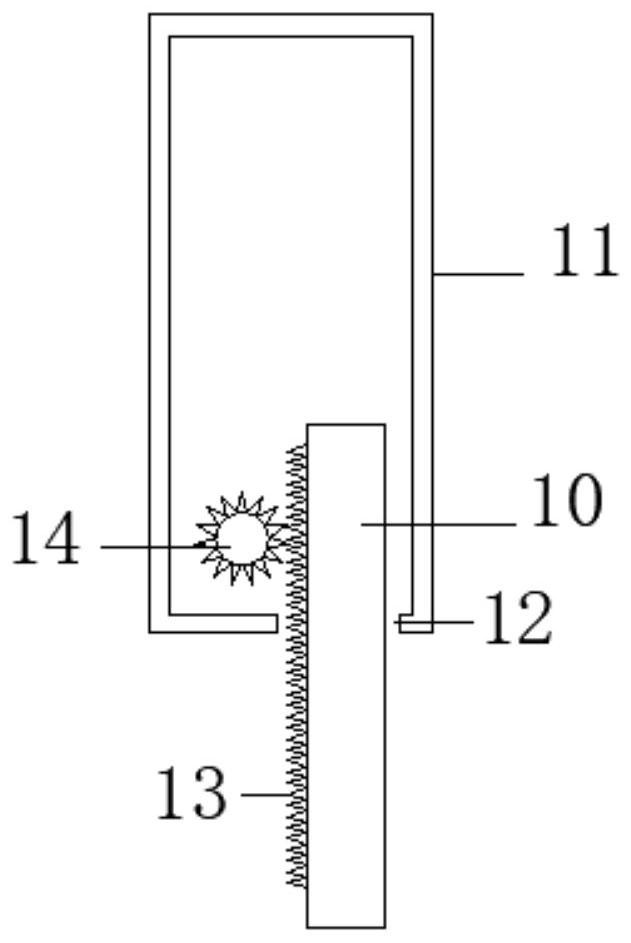

[0020] Such as Figure 1-3 As shown, the present specific embodiment adopts the following technical solutions: an automobile brake fluid draining device, comprising a draining device base 1, a plurality of moving pulleys 2 are fixedly connected to the bottom of the draining device base 1, and the moving pulleys 2 There are two, the liquid discharge device support rod 3 is fixedly installed on the other side of the liquid discharge device base 1 relative to the moving pulley 2, and the liquid discharge device support rod 3 is sleeved with a support rod inner sleeve rod 4 , the inner sleeve rod 4 of the support rod and the support rod 3 of the liquid discharging device are all dug with some same limit holes, the limit holes on the support rod 3 of the liquid discharge device and the limit holes on the inner sleeve rod 4 of the support rod The position holes are jointly inserted with an inner sleeve rod limit bolt 5, and the other end of the inner sleeve rod limit bolt 5 relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com