A kind of functional cellulose airgel composite material and preparation method thereof

A technology of cellulose aerogel and composite material, applied in the field of functional cellulose aerogel composite material and its preparation, can solve the problems of complex modification process, unsatisfactory effect and high cost, and achieves overcoming high brittleness and high product cost. Controllable style and thickness for low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

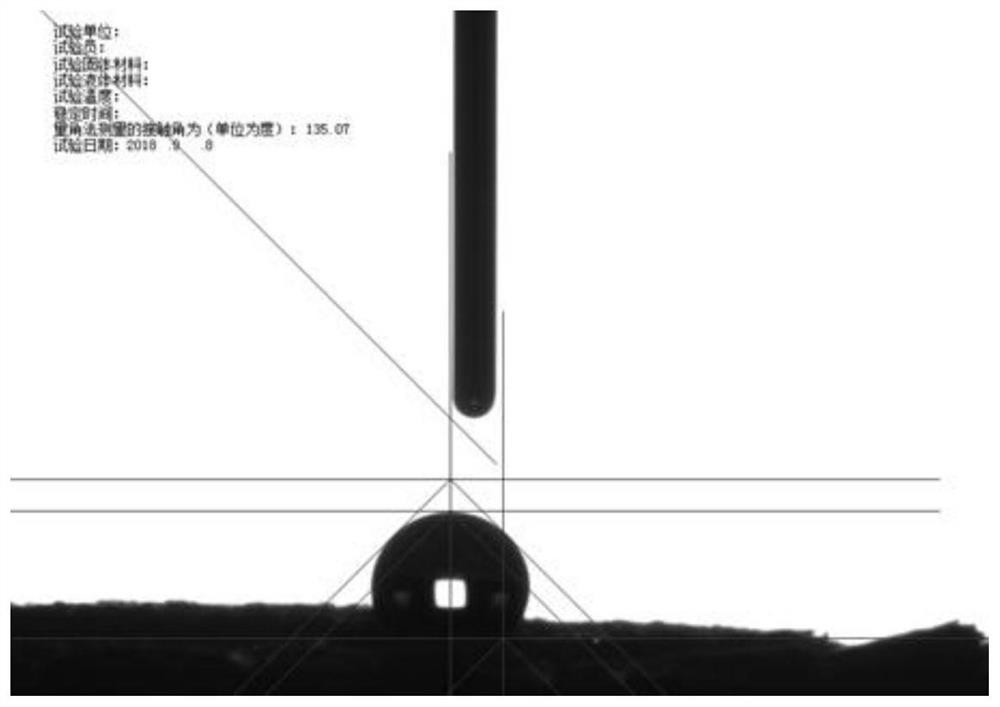

Embodiment 1

[0040] The following steps were used to prepare functional nanocellulose airgel composites:

[0041] (1) Preparation of cellulose hydrogel. Weigh nanocellulose, water, and wet strength agent with a mass ratio of 5:200:1, and ultrasonically stir in ice water to obtain cellulose hydrogel.

[0042] (2) Quickly freeze the above hydrogel in liquid nitrogen, transfer to freeze-drying equipment, pre-freeze at -30°C for 1 h, vacuumize for 0.5 h, set step temperature, and freeze-dry for 12 h to obtain nanocellulose aerogels.

[0043] (3) Prepare the sol of silicon oxide and titanium oxide. Weigh tetraethyl orthosilicate, ethanol, and water at a mass ratio of 4:12:1, and stir thoroughly at room temperature to form a colorless and transparent silicon solution. Weigh butyl titanate, ethanol, and water at a ratio of 3:10:1, and stir thoroughly at room temperature to form a colorless and transparent titanium solution. Mix the silicon-titanium solution, wherein the mass ratio of silicon o...

Embodiment 2

[0049] The following steps were used to prepare functional nanocellulose airgel composites:

[0050] (1) Preparation of cellulose hydrogel. Weigh nanocellulose, water, and wet strength agent with a mass ratio of 5:200:1, and ultrasonically stir in ice water to obtain cellulose hydrogel.

[0051] (2) Quickly freeze the above hydrogel in liquid nitrogen, transfer to freeze-drying equipment, pre-freeze at -30°C for 1 h, vacuumize for 0.5 h, set step temperature, and freeze-dry for 12 h to obtain nanocellulose aerogels.

[0052] (3) Prepare the sol of silicon oxide and titanium oxide. Weigh tetraethyl orthosilicate, ethanol, and water at a mass ratio of 4:12:1, and stir thoroughly at room temperature to form a colorless and transparent silicon solution. Weigh butyl titanate, ethanol, and water at a ratio of 3:10:1, and stir thoroughly at room temperature to form a colorless and transparent titanium solution. Mix the silicon-titanium solution, wherein the mass ratio of silicon o...

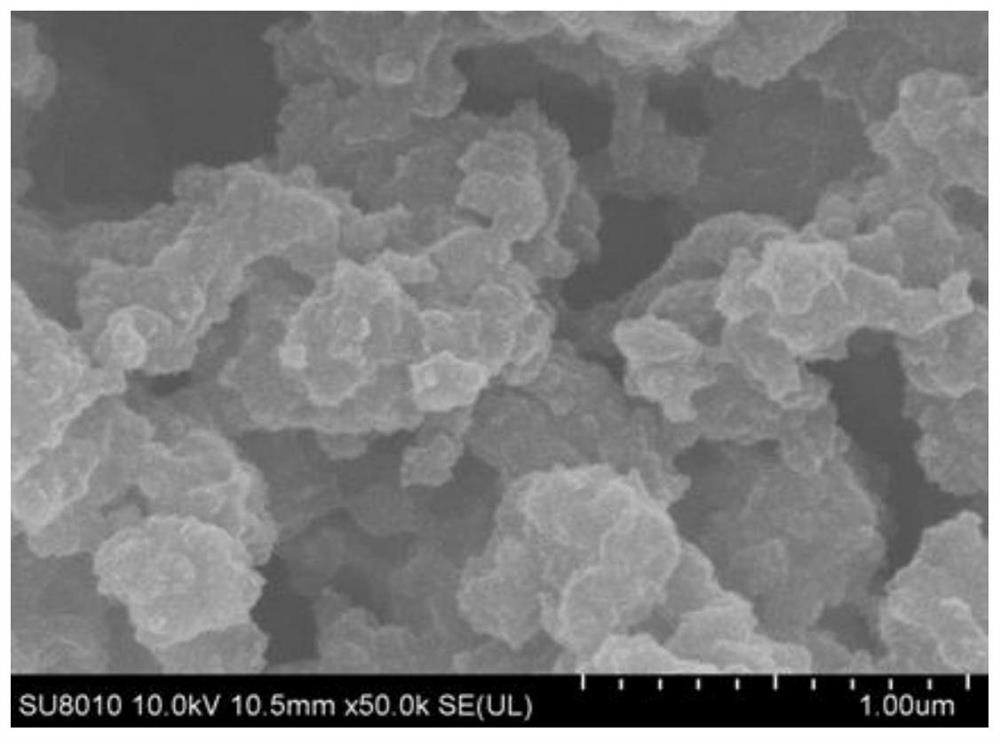

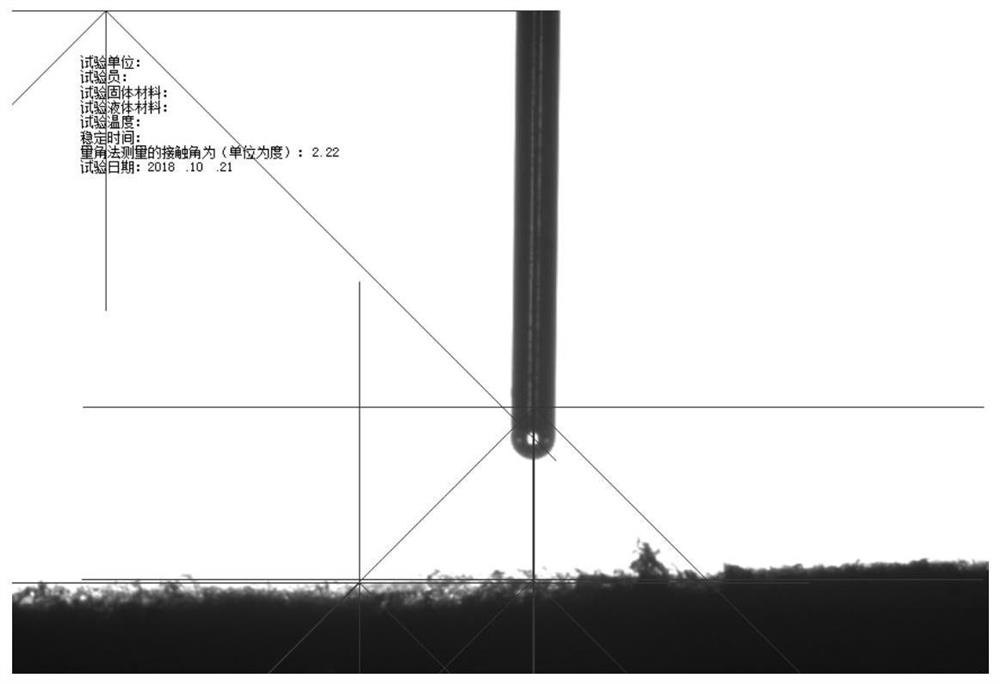

Embodiment 3

[0058] The following steps were used to prepare functional nanocellulose airgel composites:

[0059] (1) Preparation of cellulose hydrogel. Weigh nanocellulose, water, and wet strength agent with a mass ratio of 6:200:1, and stir them rapidly in ice water to obtain cellulose hydrogel.

[0060] (2) Quickly freeze the above hydrogel in liquid nitrogen, transfer to freeze-drying equipment, pre-freeze at -40°C for 1 h, vacuumize for 0.5 h, set step temperature, and freeze-dry for 12 h to obtain nanocellulose airgel.

[0061] (3) Preparation of silica sol. Weigh tetraethyl orthosilicate, ethanol, and water at a mass ratio of 4:12:1, and stir thoroughly at room temperature to form a colorless and transparent solution. Weigh methyltriethoxysilane, ethanol, and water at a ratio of 3:10:1, and stir thoroughly at room temperature to form a colorless and transparent solution. Mix the two solutions at a volume ratio of 3:1 and stir well.

[0062] (4) Mix and stir ammonia water and eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com