Fabricated T-shaped beam jacking auxiliary steel component

A prefabricated, steel component technology, applied in the direction of erecting/assembling bridges, bridges, bridge maintenance, etc., can solve the problems of consistency, danger, and jacks without insurance facilities, etc., to achieve the effect of improving stability and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

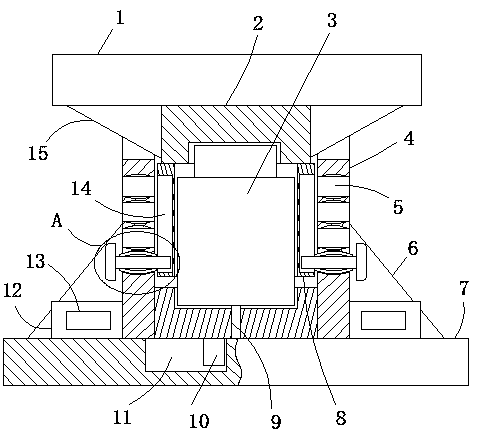

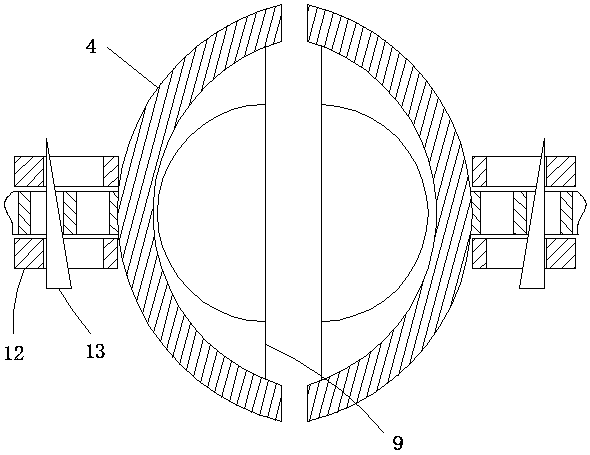

[0025] An assembled T-beam jacking auxiliary steel member, including a base 7, a top plate 1, a hydraulic cylinder 3 and two arc-shaped plates 4, the lower sides of the opposite ends of the two arc-shaped plates 4 are fixedly connected with a fixed plate 9, two The upper end of the fixed plate 9 is provided with an arc-shaped slot, the lower end of the hydraulic cylinder 3 is located in the arc-shaped slot, and the lower side of the arc-shaped plate 4 away from the fixed plate 9 is fixedly connected with a triangular plate 6, and the triangular plate 6 is connected to the base through a connecting mechanism. The upper side of 7 is connected, the lower end of the top plate 1 is fixedly connected with the installation block 2, the lower end of the installation block 2 is clamped with the upper end of the hydraulic cylinder 3 through a cylindrical groove, and the left and right sides of the lower end of the installation block 2 are fixedly connected with the limit plate 8, Limitin...

Embodiment 2

[0030] Embodiment 2: the difference based on Embodiment 1 is;

[0031] The limit mechanism includes a limit rod 21 slidingly sleeved in the limit hole 5, one end of the limit rod 21 extends into the limit groove 14, and the other end of the limit rod 21 passes through the limit hole 5 and is fixedly connected to a limited Position block 19, two arc-shaped pieces 20 are symmetrically fixedly connected on the bar wall of position-limiting rod 21, and both sides opposite in the position-limiting hole 5 are provided with draw-in grooves, and two draw-in grooves are connected with two arc-shaped pieces respectively. catch.

[0032] The limit mechanism provided in the present invention, when in use, insert the limit rod 21 into the limit hole 5, the elastic piece 20 in the limit hole 5 can cooperate with the draw-in groove to limit the limit rod 21, avoiding the use of When the limit rod 21 slides down, when the limit rod 21 is inserted in different limit holes 5, it can cooperate wi...

Embodiment 3

[0033] Embodiment 3: the difference based on embodiment 1 is;

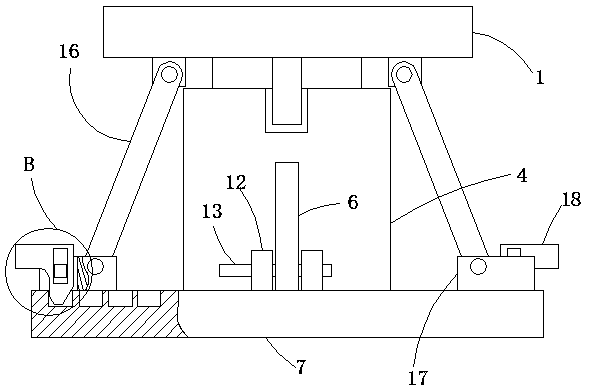

[0034] The fixing mechanism includes an upside-down L-shaped block 18 arranged in the through groove, a rectangular opening is vertically opened at the bending part of the L-shaped block 18, and a rectangular rod 22 is slidingly sleeved in the rectangular opening. The opposite sides of the grooves are fixedly connected, the lower end of the L-shaped block 18 extends into one of the fixed grooves and has an inclined surface 23, and the corner of the vertical part of the L-shaped block 18 away from the inclined surface 23 is provided with a chamfer twenty four.

[0035] The fixing mechanism provided in the present invention, when in use, when the hydraulic cylinder 3 lifts the top plate 1, the push rod 16 swings around the pivot pin, and then the fixing block 17 slides on the base 7, and when the fixing block 17 slides, the L-shaped block 18 The inclined surface on the top slides through the fixing groove, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com