Fabricated steel structure and prefabricated building

A prefabricated, steel structure technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of reducing the flexibility of space layout, affecting the utilization of indoor space, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

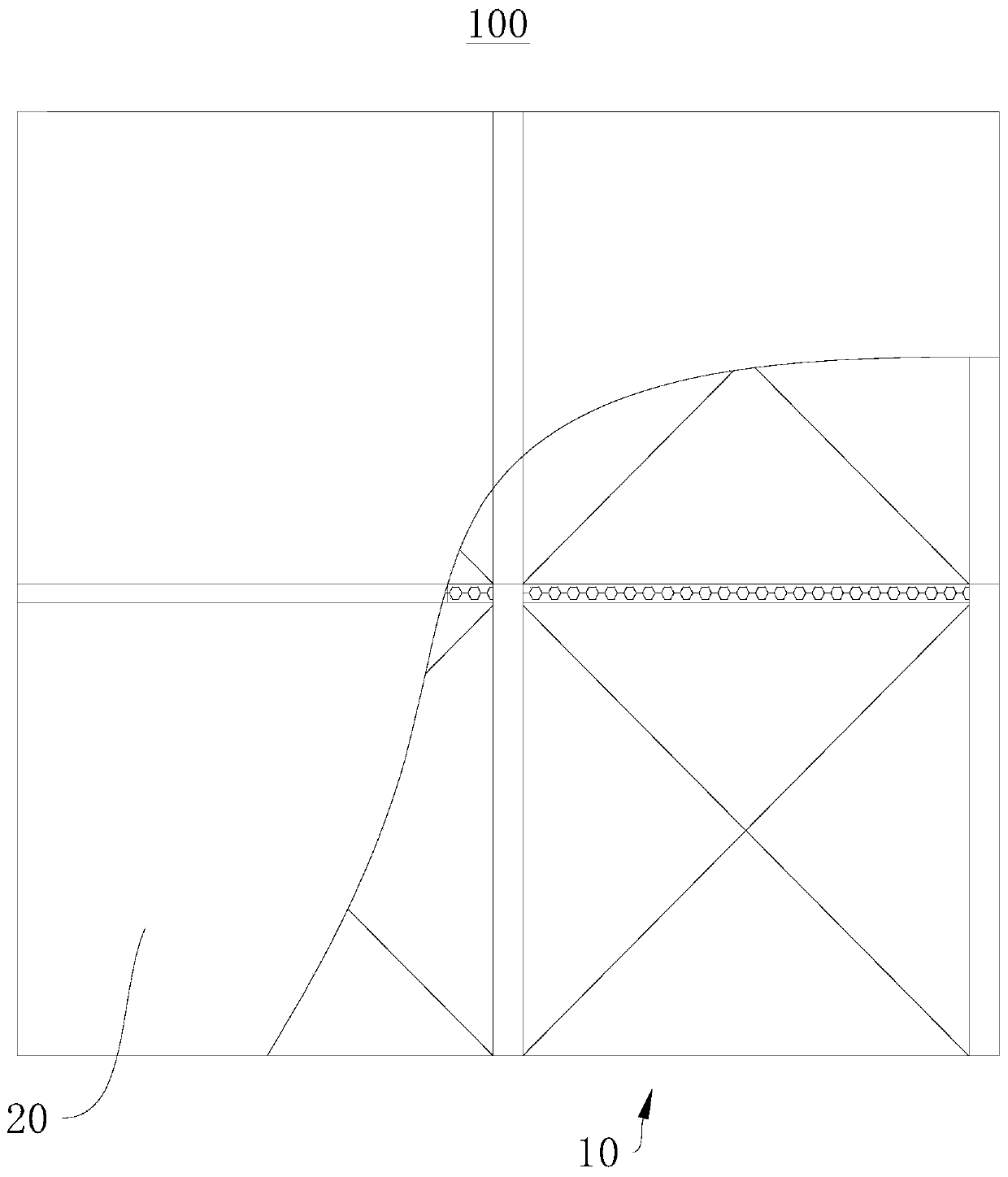

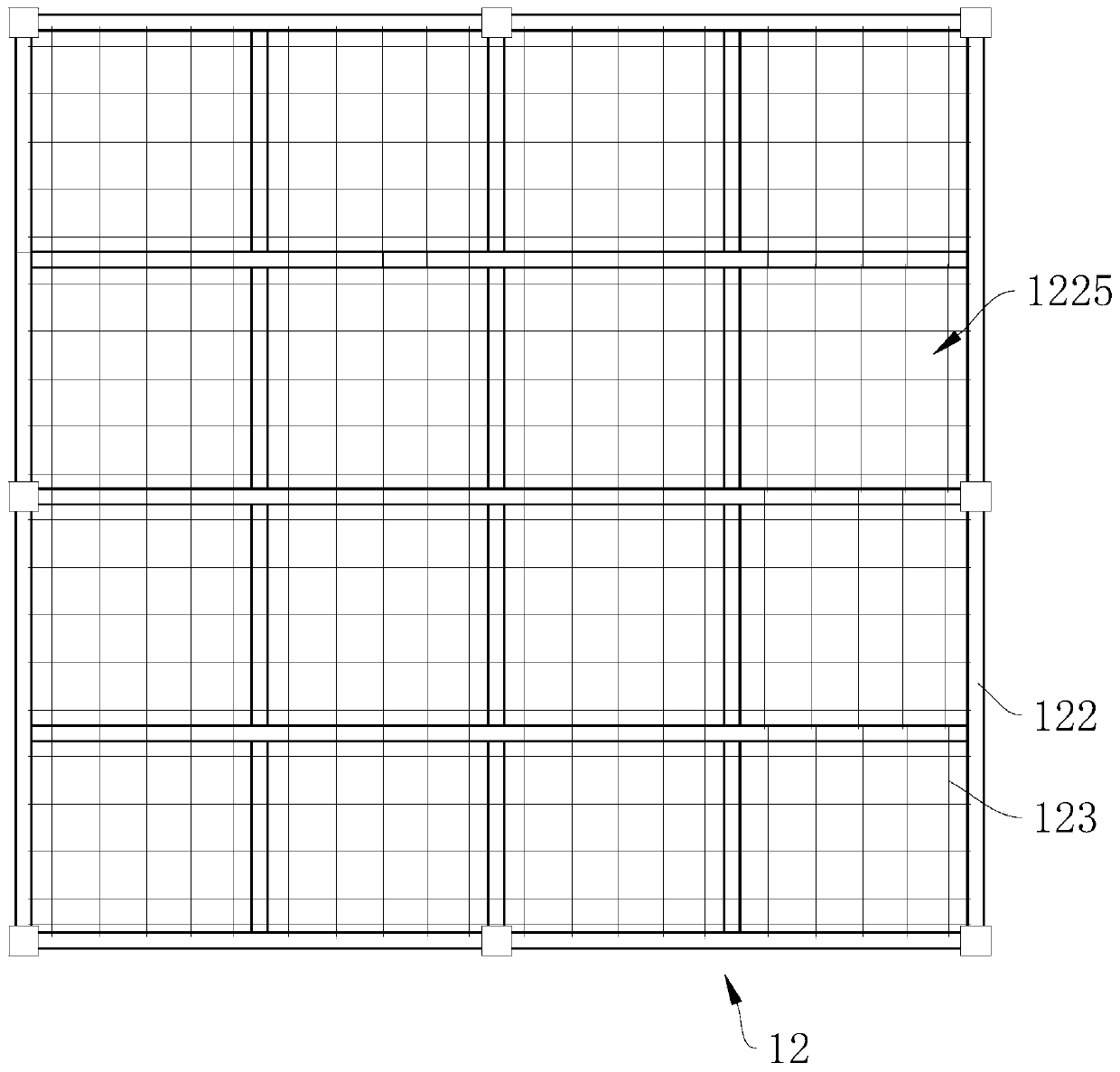

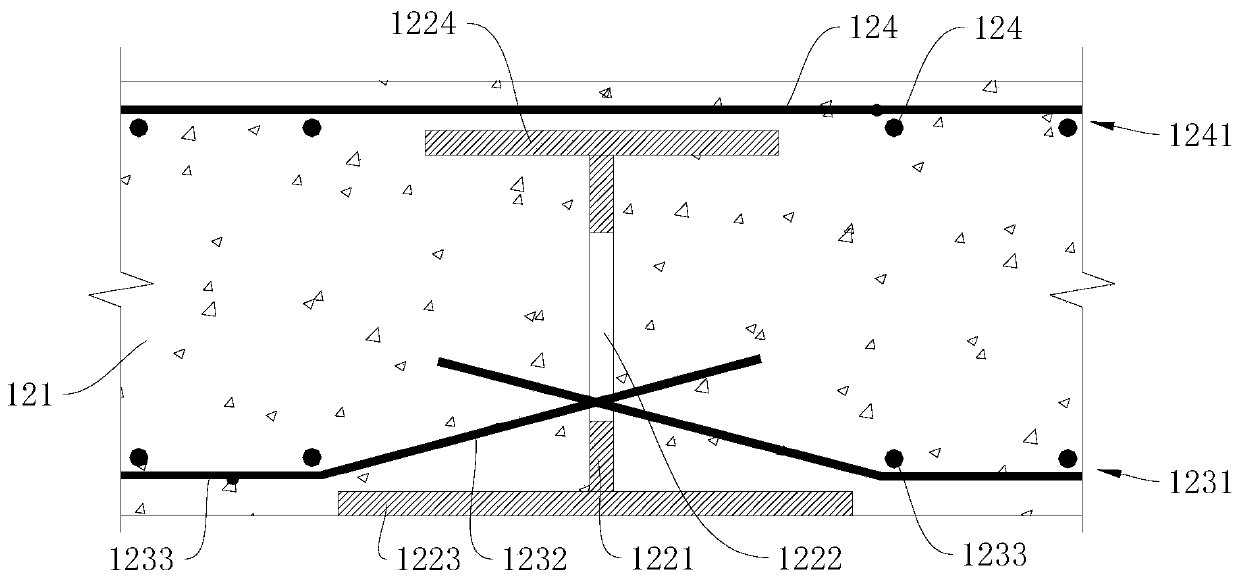

[0033] see figure 1 , figure 1 It is a partially cut-away schematic diagram of the prefabricated steel structure 10 applied to the prefabricated building 100 provided by the embodiment of the present invention.

[0034] The embodiment of the present invention provides a prefabricated steel structure 10. The bottom surface of the prefabricated steel structure 10 is relatively flat and has no protruding beams, and it has the characteristics of flexible arrangement convenient for space. The prefabricated steel structure 10 can be applied to buildings such as the prefabricated building 100 . Of course, the fabricated steel structure 10 can be used in low-rise residential buildings and public buildings.

[0035] Among them, taking the prefabricated steel structure 10 applied to the prefabricated building 100 as an example, the prefabricated structure includes the above-mentioned prefabricated steel structure 10, and through the prefabricated steel structure 10, the bottom of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap