Installation method of rotary kiln

An installation method and technology of rotary kiln, applied in rotary drum furnace, lifting device, lifting frame, etc., can solve problems such as time-consuming, difficult to ensure absolute roundness, error, etc., and achieve the effect of improving calibration accuracy and level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

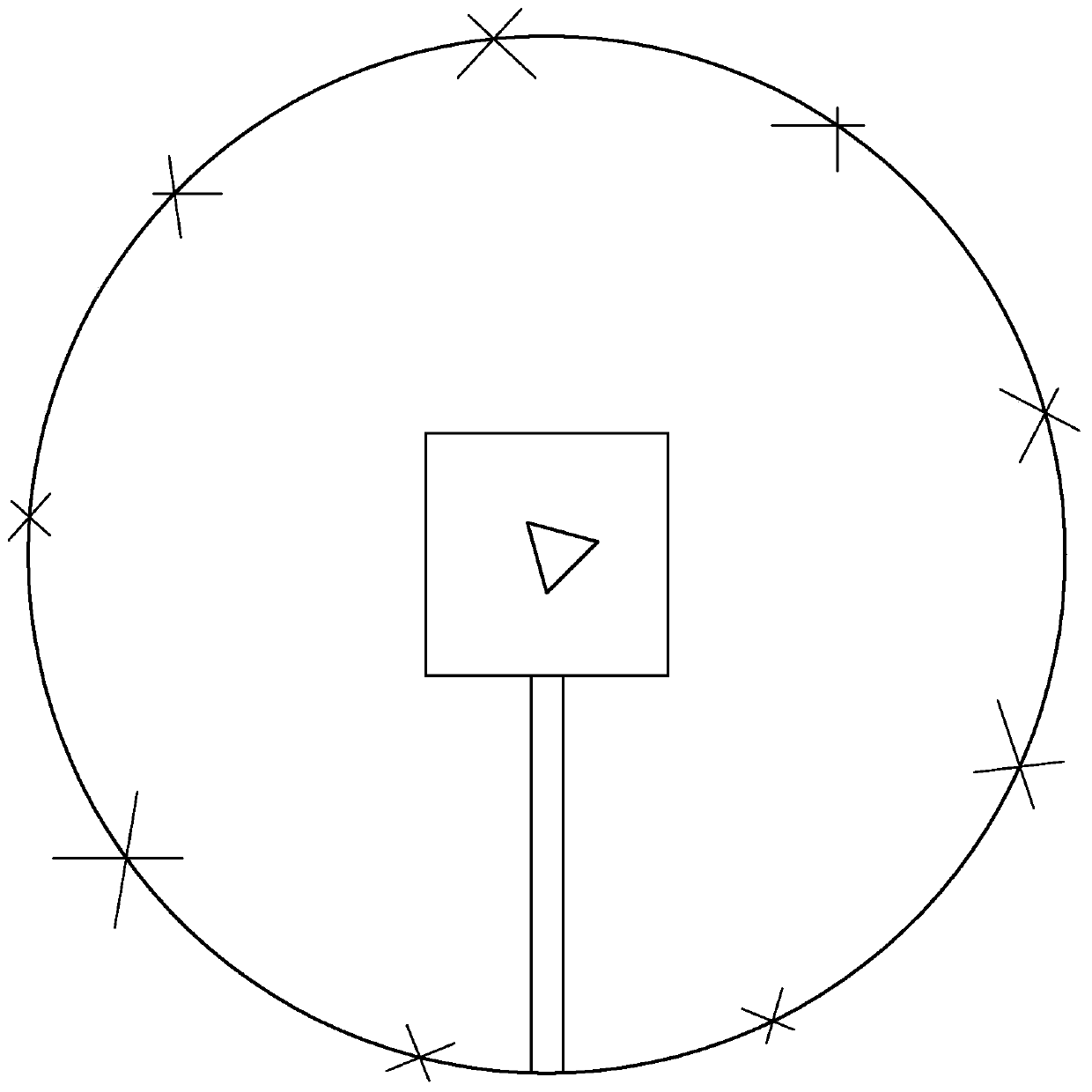

[0045] The invention introduces a method for installing a rotary kiln, which includes the following steps:

[0046] S1, forming and installing the base;

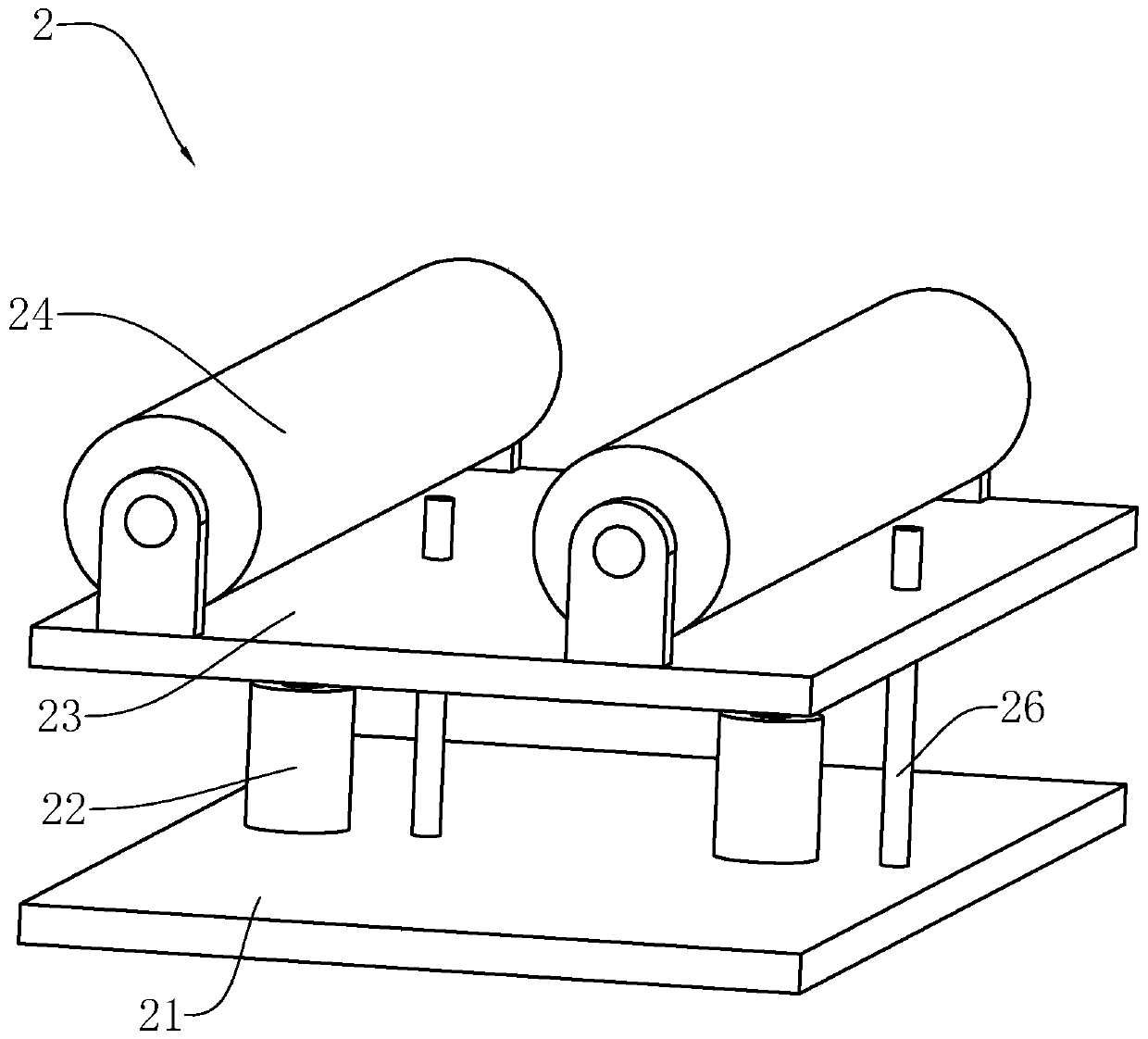

[0047] S2, install the supporting wheel and the retaining wheel on the base;

[0048] S3. Precisely adjust the position of the supporting wheel, find the alignment, and then perform secondary fixation;

[0049] S4. Hoist the cylinder body of the rotary kiln above the supporting wheel, and let the cylinder body and the supporting wheel roll and connect;

[0050] S5. Alignment and welding of the cylinder;

[0051] S6, install and align and fix the transmission device.

[0052] Each step is described in detail below.

[0053] In step S1, before forming the base, it is necessary to draw a line according to the installation position of the cylinder, etc., and then pour the foundation of the forming base according to the position of the marking. A layer of steel base can be laid.

[0054] A set of shim irons shall be provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com