Anchorage structural surface shear strength size effect test system

A technology of shear strength and size effect, applied in the direction of strength characteristics, using a stable shear force to test the strength of materials, instruments, etc., can solve problems such as the inability to meet the shear strength test requirements of large multi-scale samples with anchors , to achieve good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

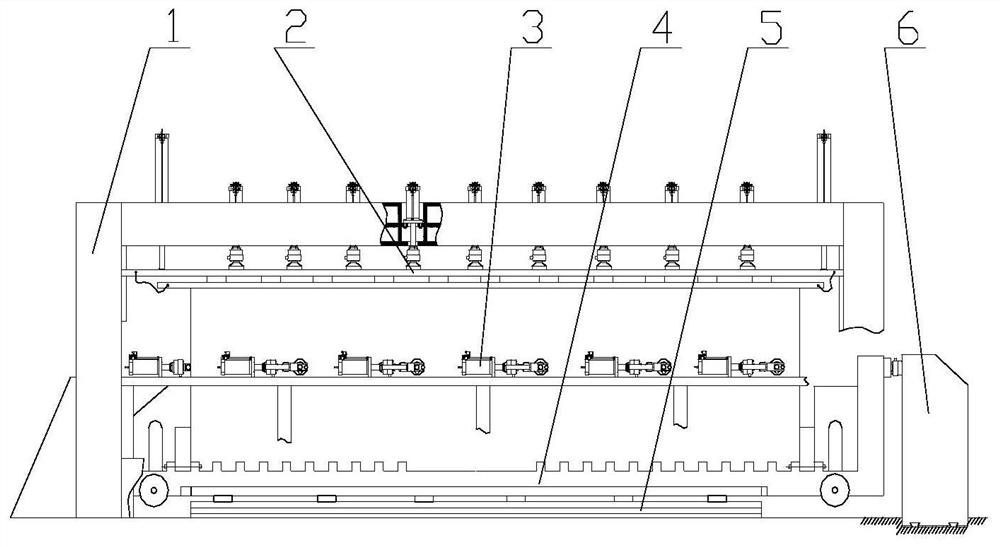

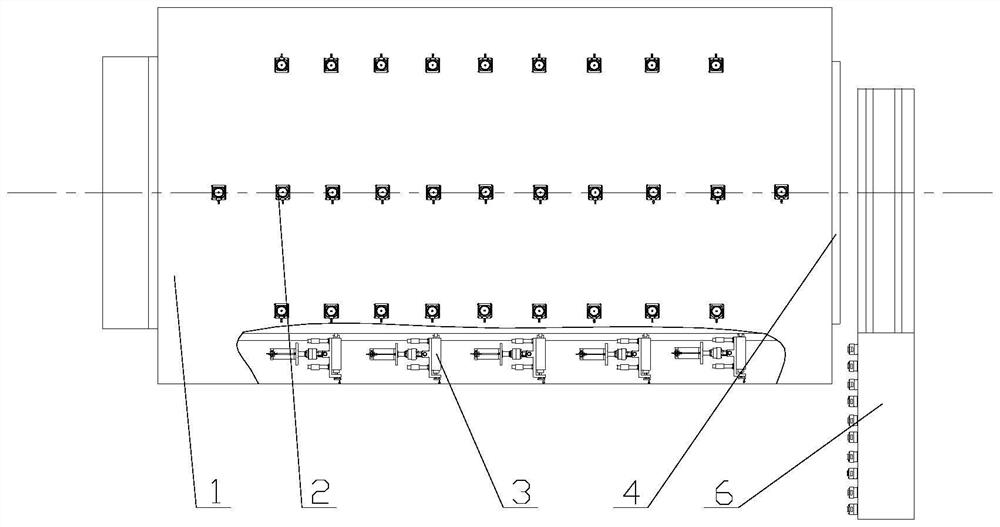

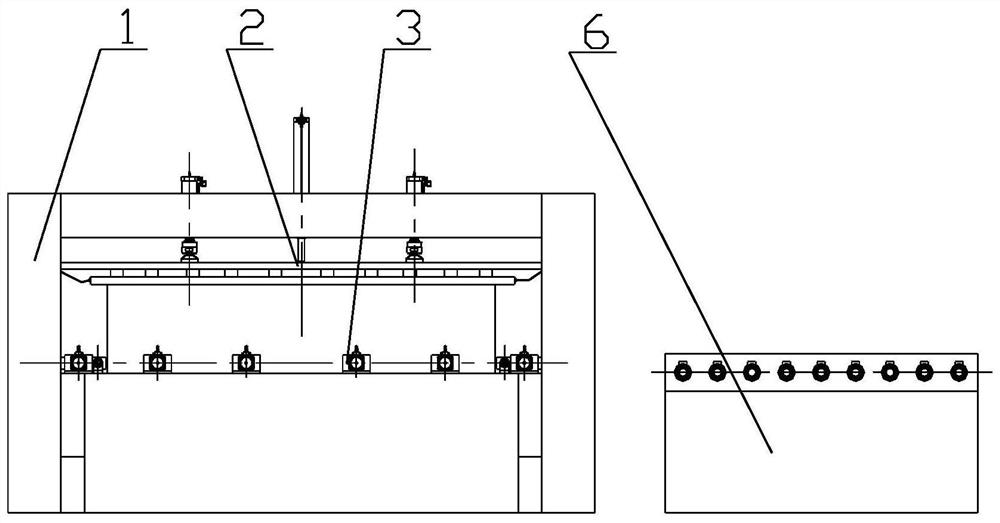

[0029] refer to Figure 1 to Figure 12 , Anchoring structure surface shear strength size effect test system, including frame 1, normal loading mechanism 2, tangential loading mechanism 3, sample transport trolley 4, height adjustment mechanism 5 and support force measuring mechanism 6, normal loading mechanism 2 Installed on the upper part of the frame 1 and above the sample, the tangential loading mechanism 2 is installed in the middle of the frame 1 and in the middle of the sample, the height adjustment mechanism 5 is installed at the bottom of the frame 1, and the sample transport trolley 4 is located above the height adjustment mechanism 5, supporting The force measuring mechanism 6 is located on the right side of the frame 1 .

[0030] Further, the frame 1 includes a left column 11, a top beam 12, a bottom beam 13, a tangential loading mounting frame 14, a right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com