Unidirectional MEMS microphone and production method thereof

A production method and microphone technology are applied in the field of microphones to achieve the effect of reducing the volume of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

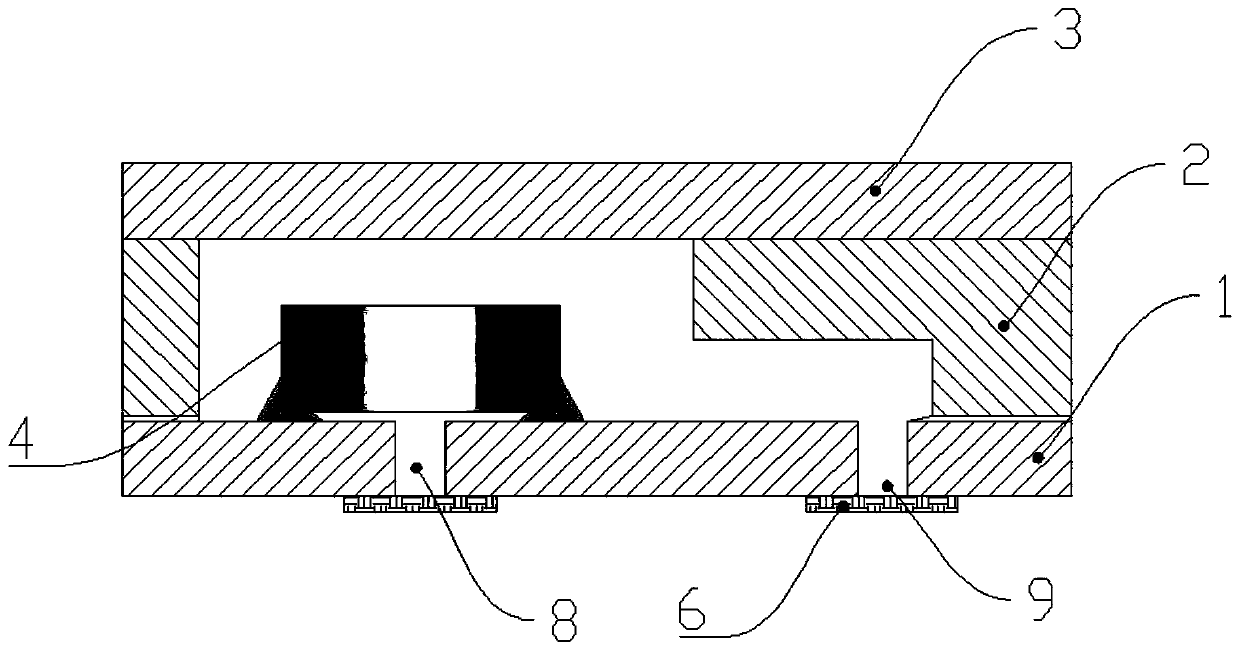

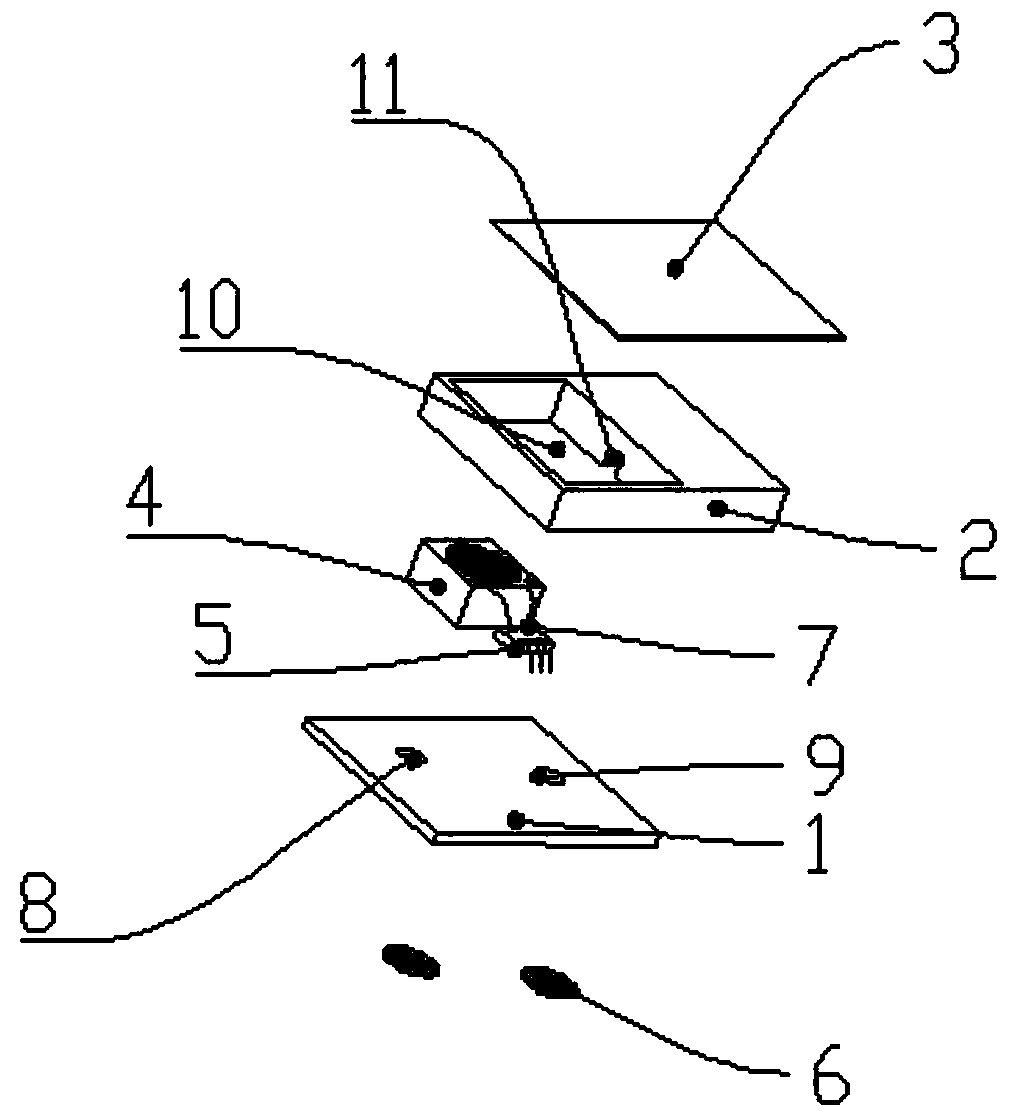

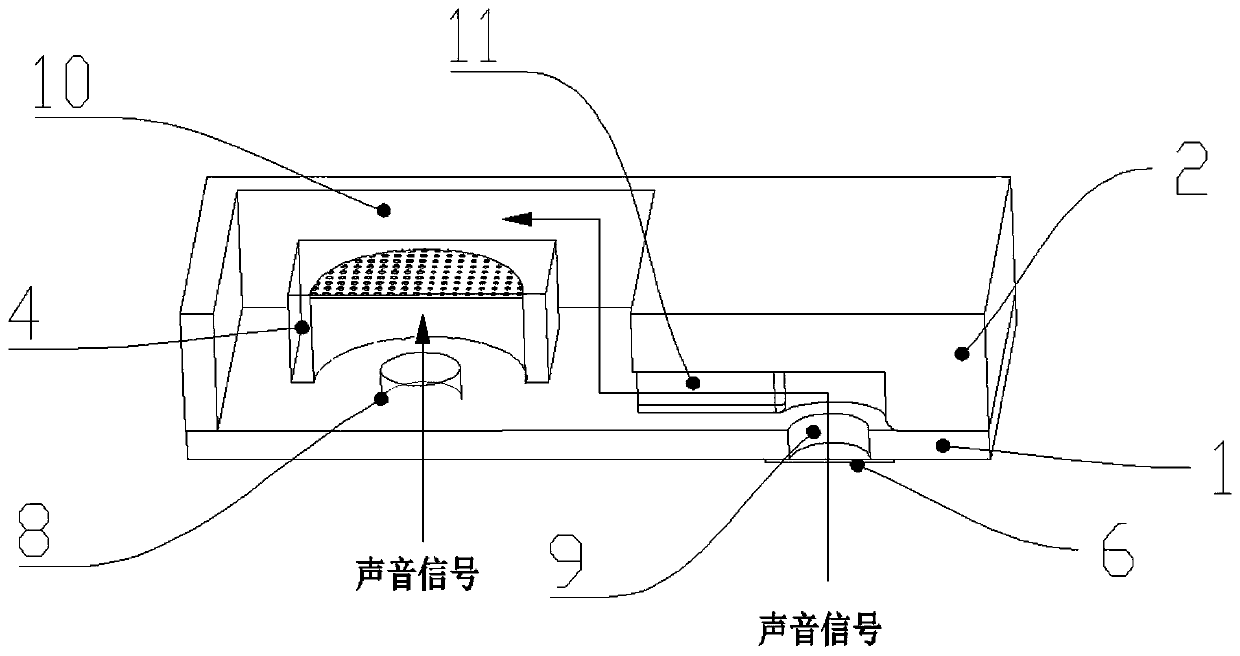

[0033] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

[0034] like Figure 1 to Figure 8 As shown, the present invention discloses a unidirectional MEMS microphone and a production method thereof, which are composed of a PCB upper layer 1, a PCB middle layer 2 and a PCB lower layer 3, and an acoustic cavity is formed after the PCB upper layer 1, PCB middle layer 2 and PCB lower layer 3 are assembled 10. The first sound hole 8 and the second sound hole 9 penetrating through the upper PCB layer 1 are respectively fixed on the upper layer 1 of the PCB. Both are fixed with damping mesh 6, the first acoustic hole 8 is connected to the acoustic cavity 10, the second acoustic hole 9 is connected to the acoustic cavity 10 through the air guide groove 11 provided on the middle layer 2 of the PCB, and the MEMS chip 4 is fixed inside the acoustic cavity 10, MEMS The chip 4 includes an annular silicon base 402 surrounding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com