Three-stage unfreezing method for frozen beef

A frozen beef, three-stage technology, applied in the direction of preservation of meat/fish by freezing/cooling, etc., can solve the problems of decreased meat quality, unfavorable microbial reproduction, and no mention of the humidity setting during the thawing process. The effect of rising too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Beef frozen processing method: Remove surface fat, fascia and separable connective tissue from fresh whole Niu Lin, cut into meat pieces with similar quality and shape (800±20g, 15cm×10cm×8cm), group them randomly, and use Pack it with polyethylene film and freeze it quickly at -40°C. After it is completely frozen, transfer it to a refrigerator at -18°C for 7 days.

Embodiment 2

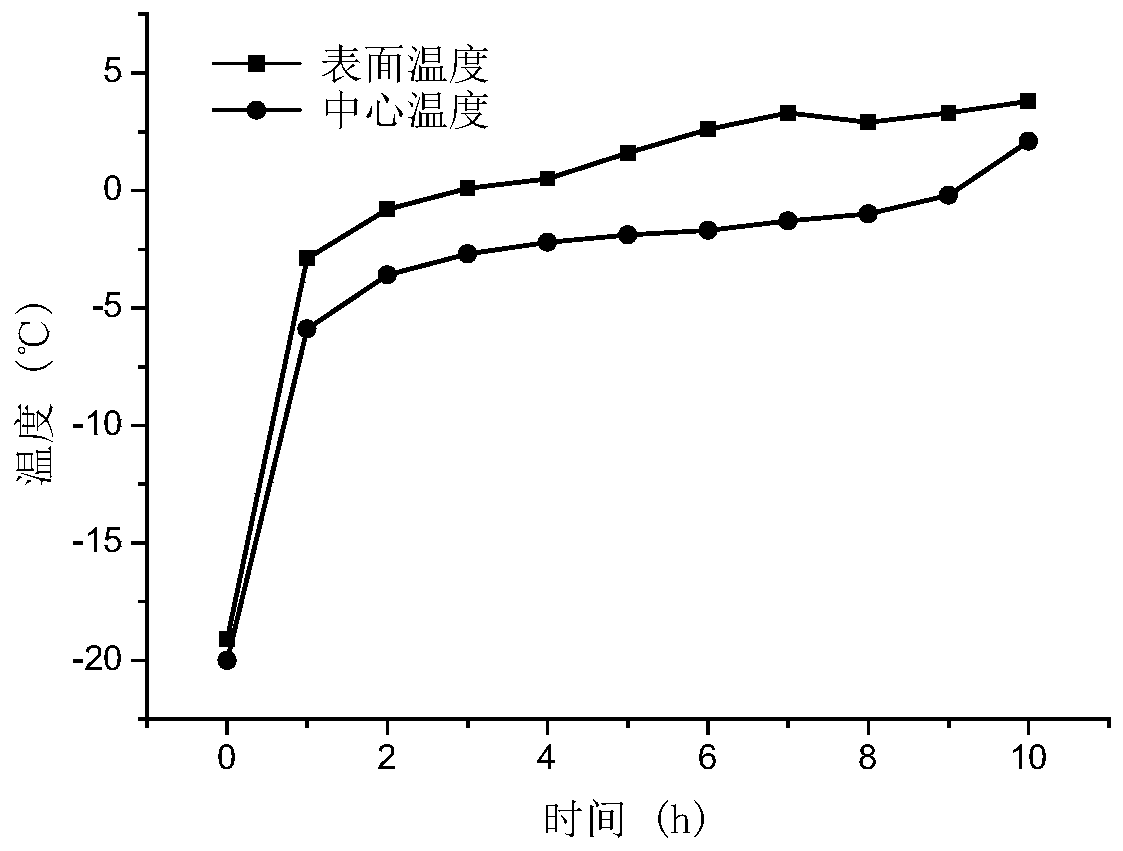

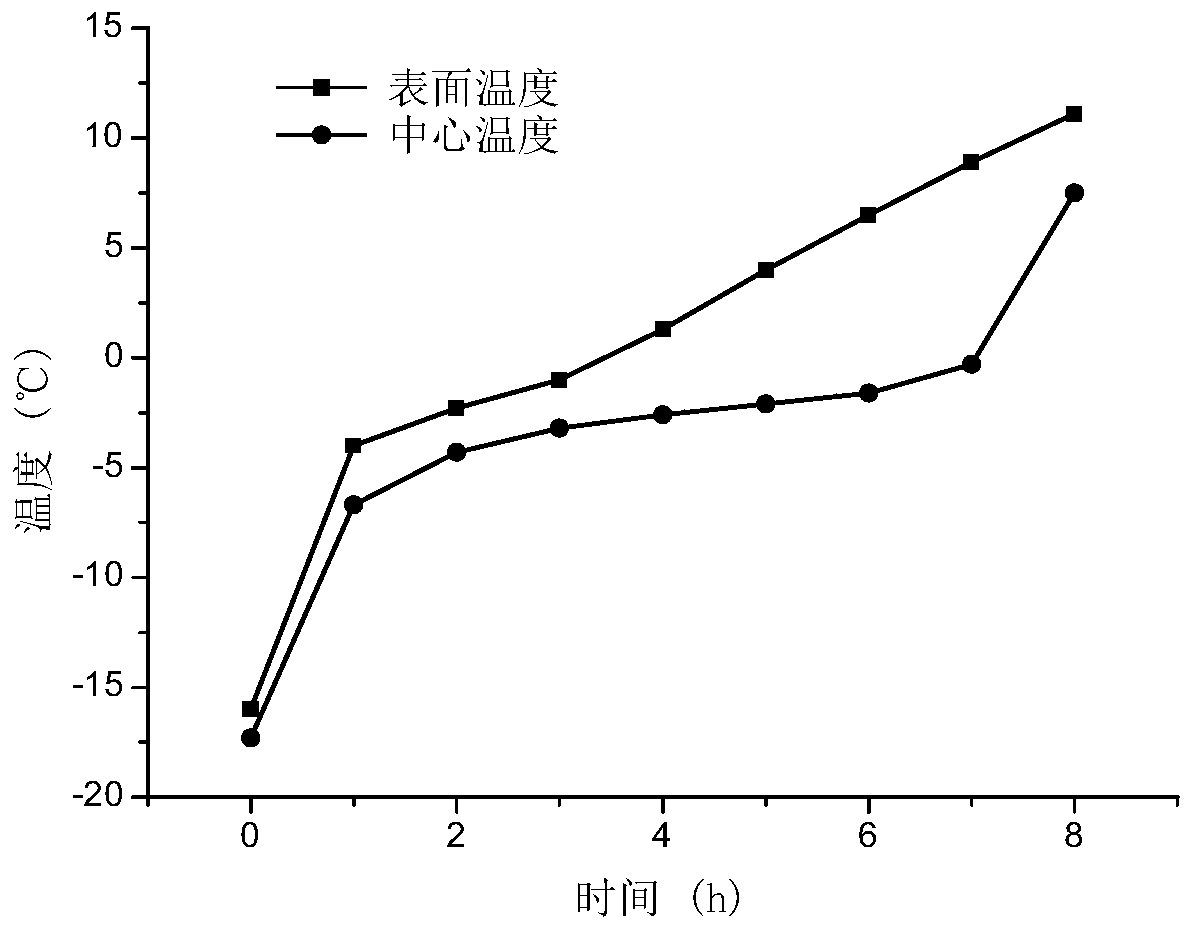

[0035] A three-stage method for thawing beef with variable temperature and humidity, specifically comprising the following steps:

[0036] S1, set the relative humidity in the thawing store to 75%, and adjust the temperature to 20°C. After reaching the preset temperature and humidity, place the beef sample frozen according to the method in Example 1 in the thawing store to start thawing, wherein the frozen meat is below the surface Temperature sensors are inserted at the position at 0.5 cm and at the geometric center respectively.

[0037] S2, when it is detected that the surface temperature of the frozen meat reaches 0°C, the temperature in the thawing storage is adjusted to 8°C, the humidity is adjusted to 95%, and then the thawing continues.

[0038] S3, when it is detected that the temperature of the center of the frozen meat reaches -1°C, the temperature in the thawing store is adjusted to 5°C, the humidity is adjusted to 98%, and the thawing is continued until the center t...

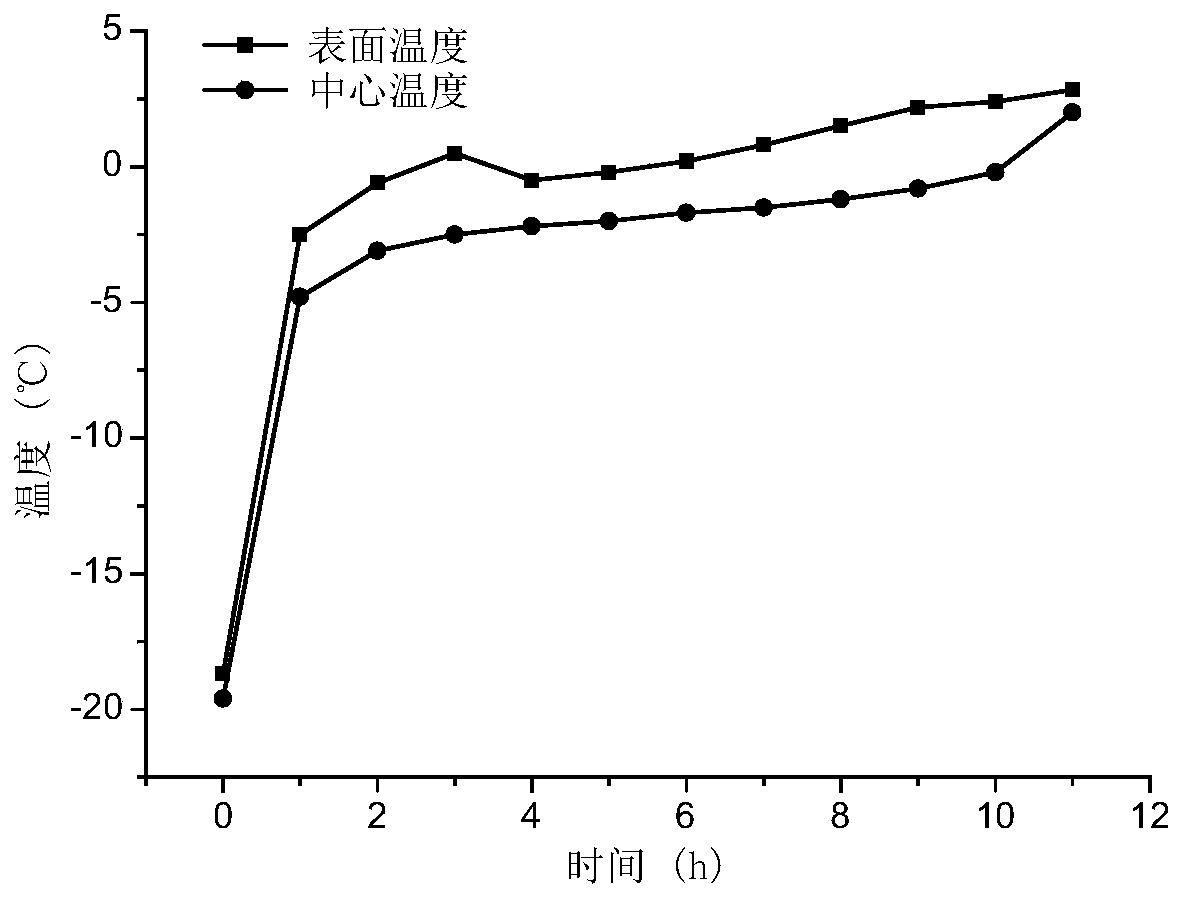

Embodiment 3

[0040] A three-stage method for thawing beef with variable temperature and humidity, the specific steps are the same as those in Example 2, the only difference being:

[0041] S2, when it is detected that the surface temperature of the frozen meat reaches 0°C, the temperature in the thawing storage is adjusted to 5°C, and the humidity is adjusted to 95%.

[0042] S3, when it is detected that the temperature of the center of the frozen meat reaches -1°C, the temperature in the thawing store is adjusted to 2°C, and the humidity is adjusted to 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com