Repairing, designing and manufacturing method of removable partial dentures

A manufacturing method and technology of dentures, applied in the direction of additive manufacturing, manufacturing tools, metal processing equipment, etc., can solve the problems of unsatisfactory tissue health care, functional reconstruction and aesthetic restoration, large errors, low precision, etc., and achieve long-term improvement Success rate and repair effect, reduction of non-physiological lateral force, and effect of improving aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0018] A kind of restoration design and manufacture method of removable partial denture of the present invention of the present invention has the following steps:

[0019] 1) Three-dimensional scanning of the dentition and gums that need to be repaired with removable partial dentures, recorded as data D;

[0020] 2) Use CAD software to design denture rests, retainers, connectors, bases, and artificial teeth;

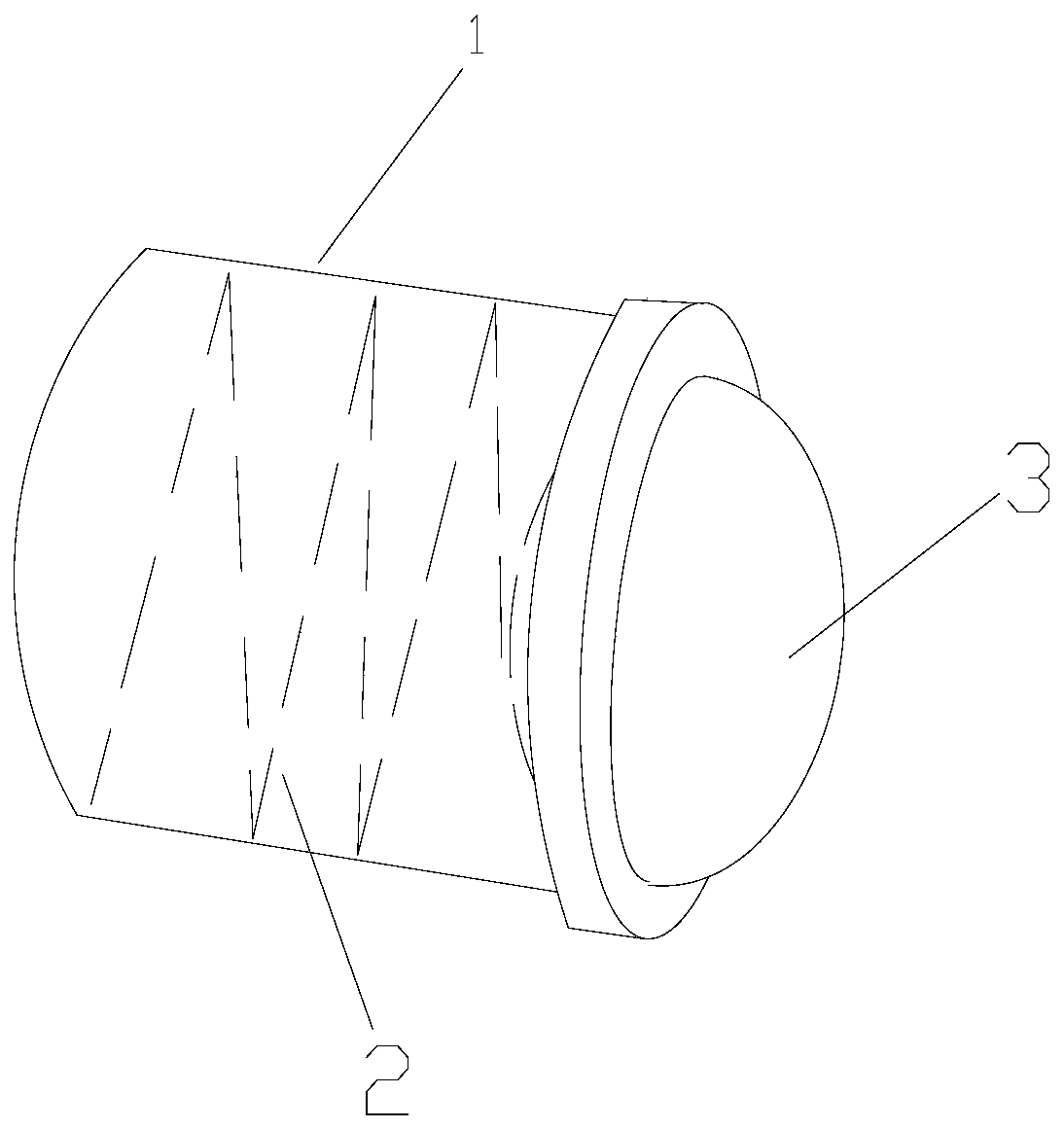

[0021] 3) Design a press-in ball head spring plunger structure in the area of the denture guide plane, as a retaining device to replace various denture snap rings;

[0022] 4) Design gap cards between teeth that are prone to food impaction;

[0023] 5) Data fusion of various structures designed above with data D to complete the three-dimensional design of the repaired removable partial denture;

[0024] 6) Use a 3D printer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com