Punching machine and punching feeding device for flexible material

A flexible material and punching machine technology, applied in metal processing and other directions, can solve the problems of reduced tool life, high punching pressure, and no punching mechanism, so as to improve speed and efficiency, avoid excessive impact, and ensure service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

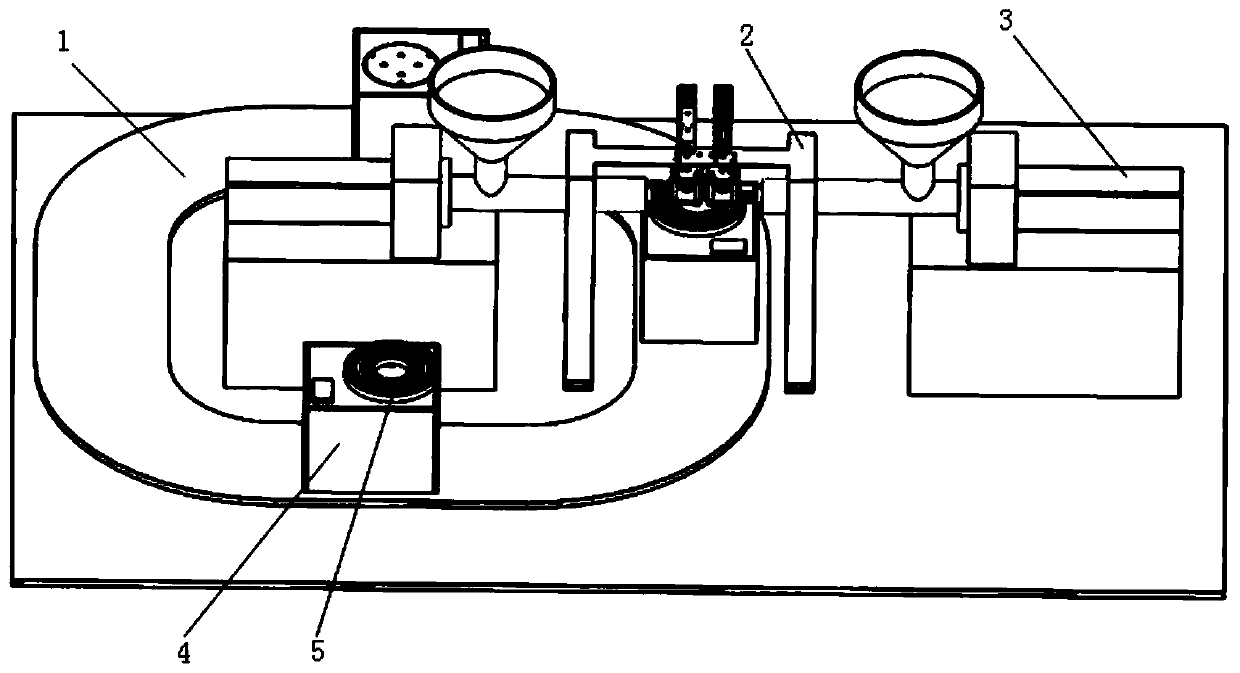

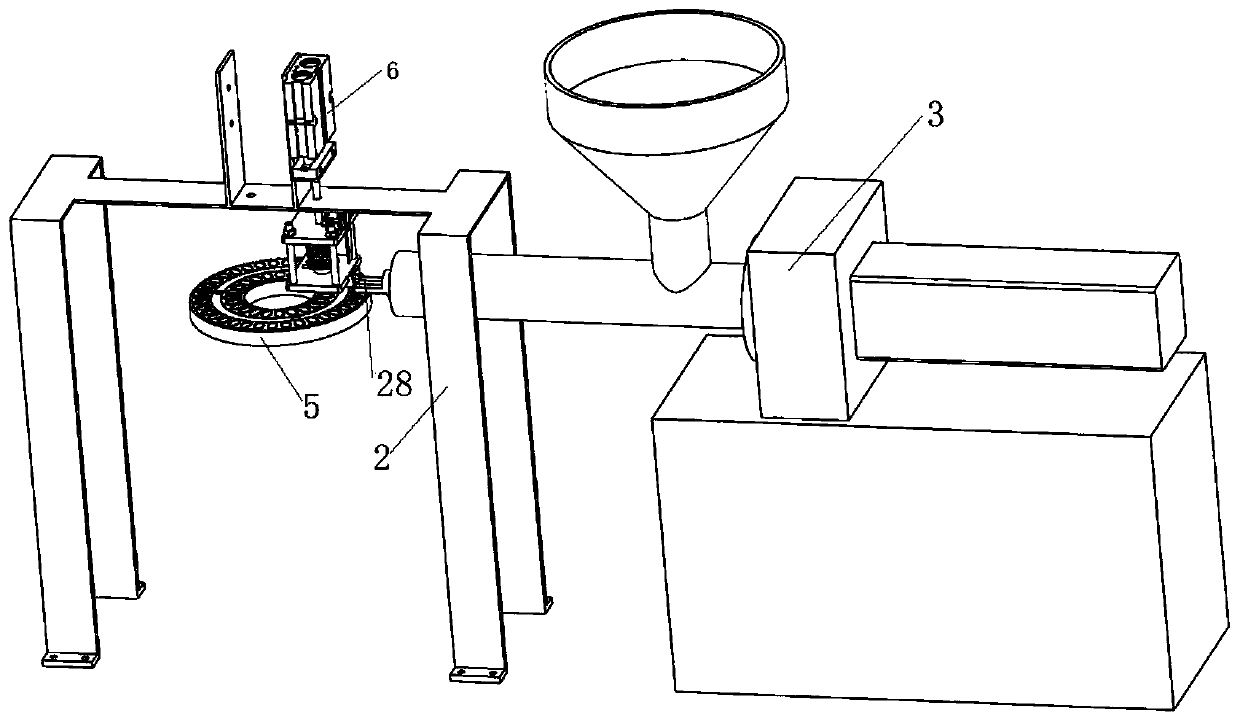

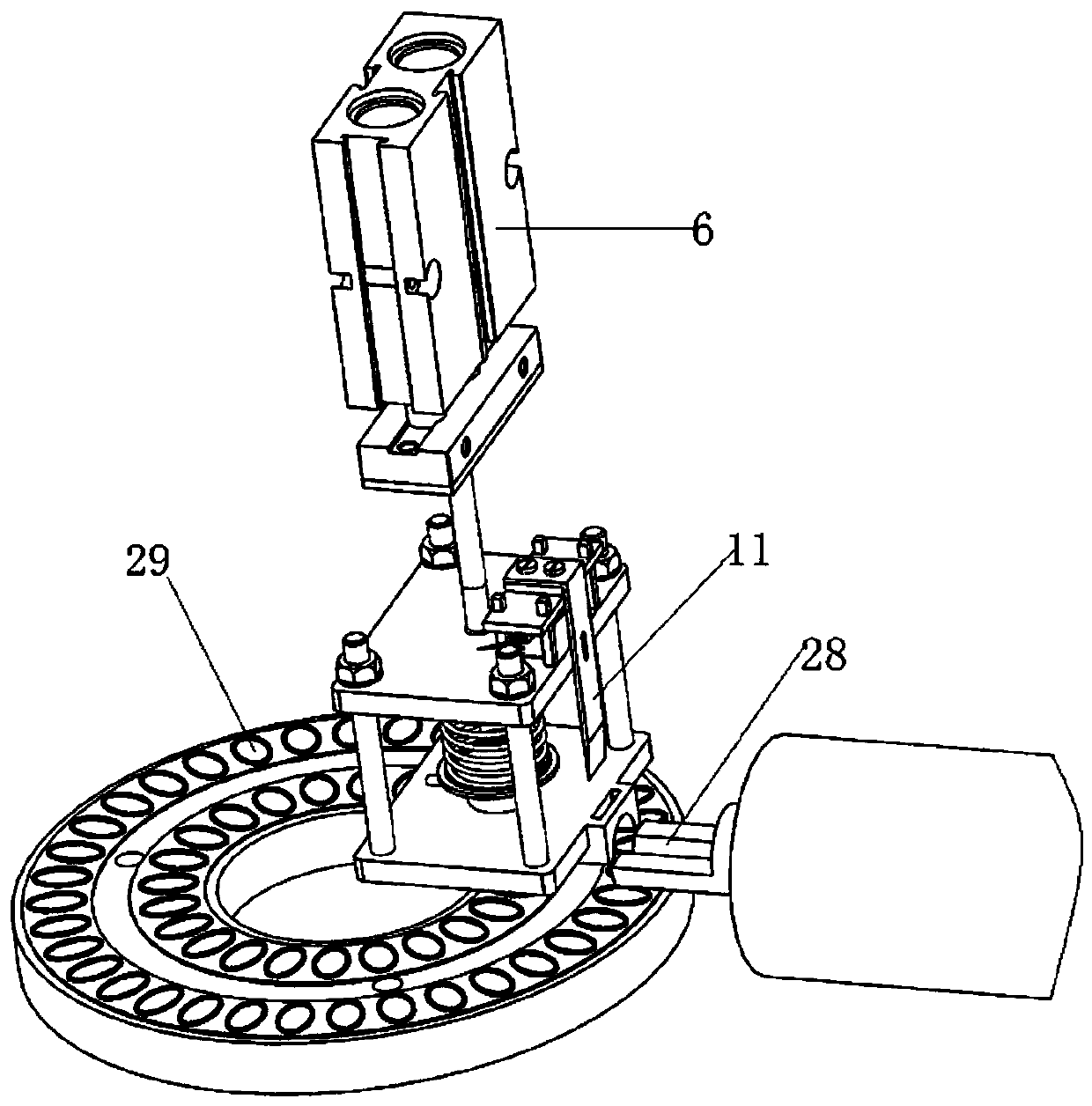

[0053] A flexible material punching feeding device, such as Figure 1-Figure 4 As shown, the extruder 3, the shearing machine described in Embodiment 1, the conveying mechanism 1 and the platform module 4 are included, the extruder 3 is used to extrude the strip-shaped material, and the shearing machine is used to carry out the strip-shaped material according to different lengths. Automatic cutting, the platform module 4 is fixed on the surface of the transmission mechanism 1, the transmission mechanism 1 is used to drive the platform module 4 to realize rotation, the cutting machine is supported by the bracket 2, and the bracket 2 is set across the width of the transmission mechanism 1, and the transmission mechanism 1 drives the platform module 4 Movement After setting the angle, it can move to the bottom of the bracket 2.

[0054] Wherein, mold 5 is provided with two circles of mold grooves 29, and extruder comprises two, and two extruders 3 are located at the both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com