Plastic product automatic screening and processing assembly line and processing method

A plastic product, automatic screening technology, applied in plastic recycling, lighting and heating equipment, drying, etc., can solve the problem of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

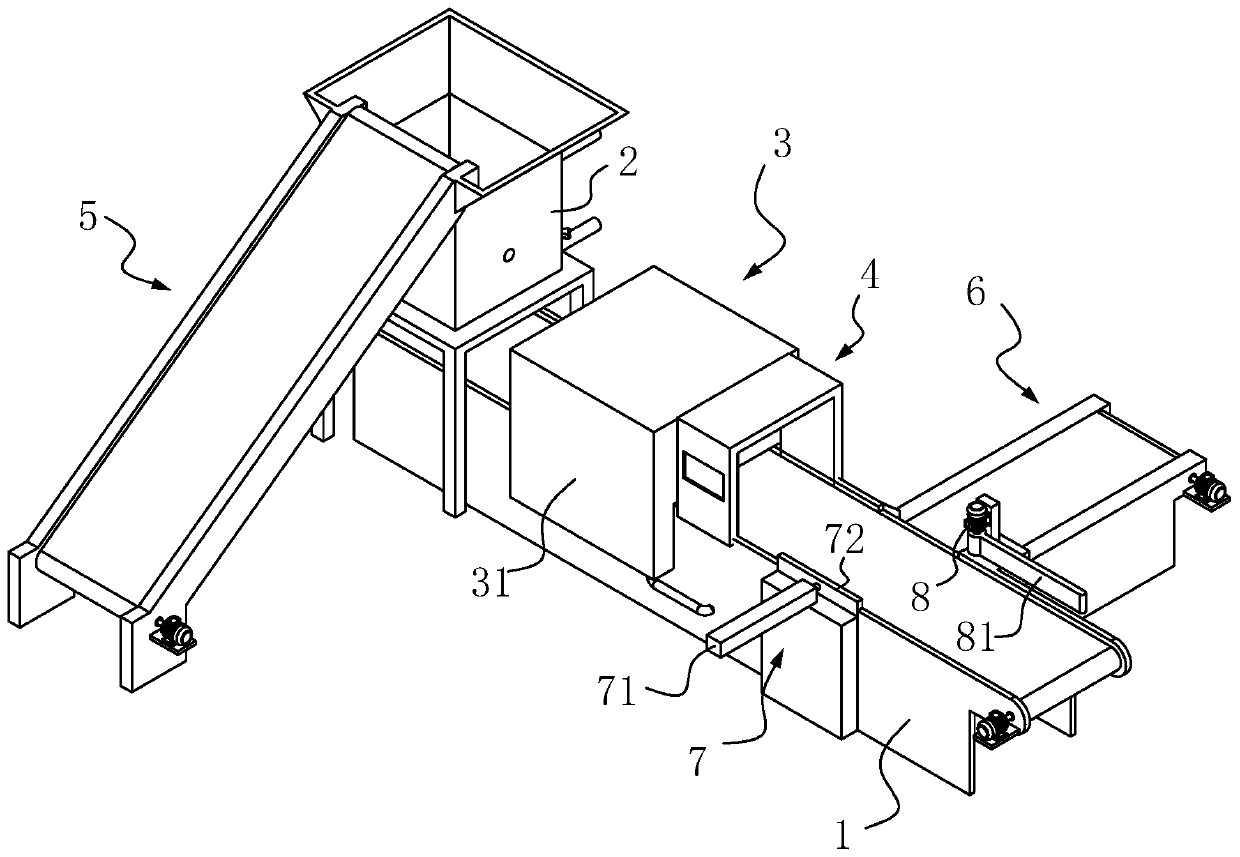

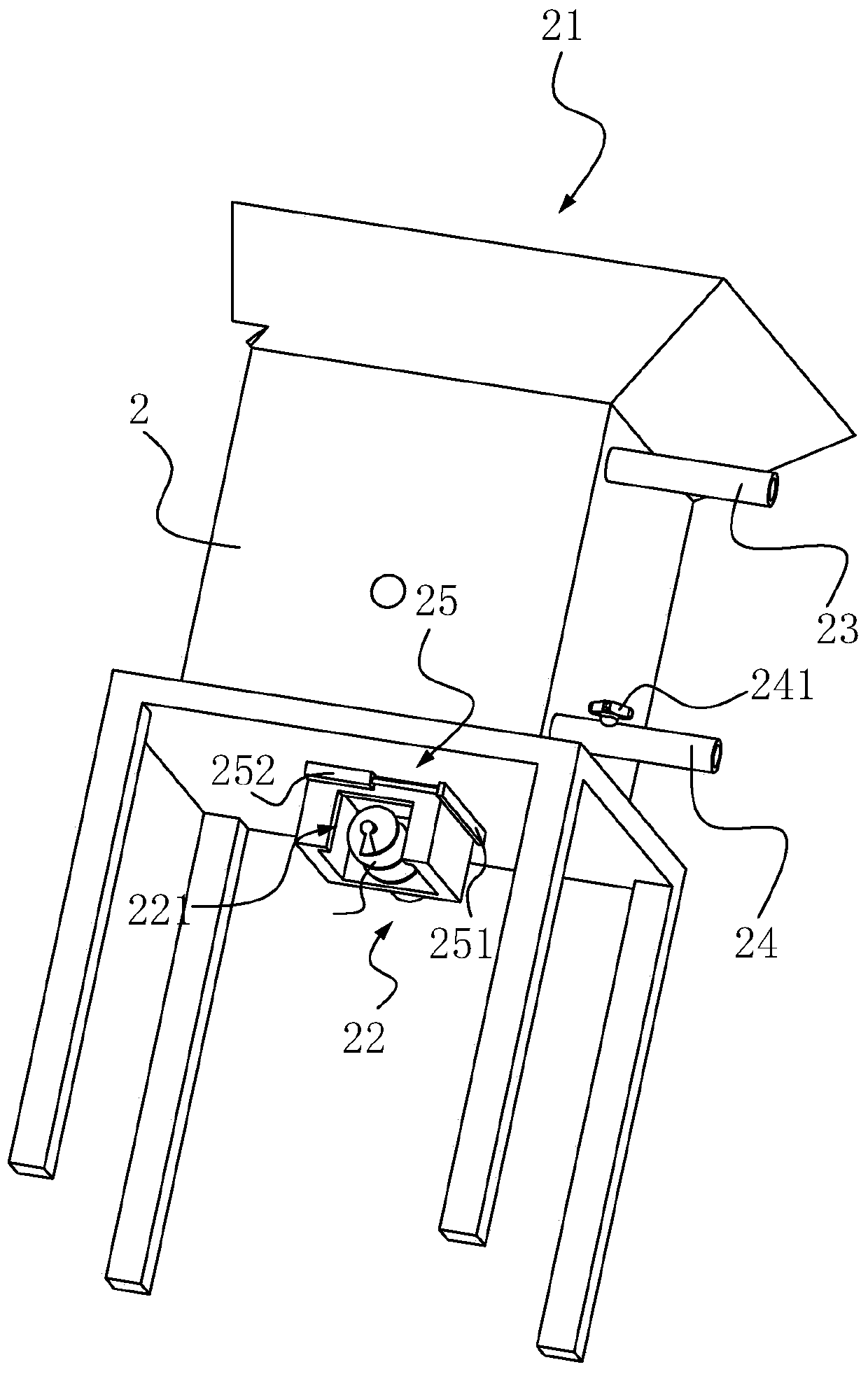

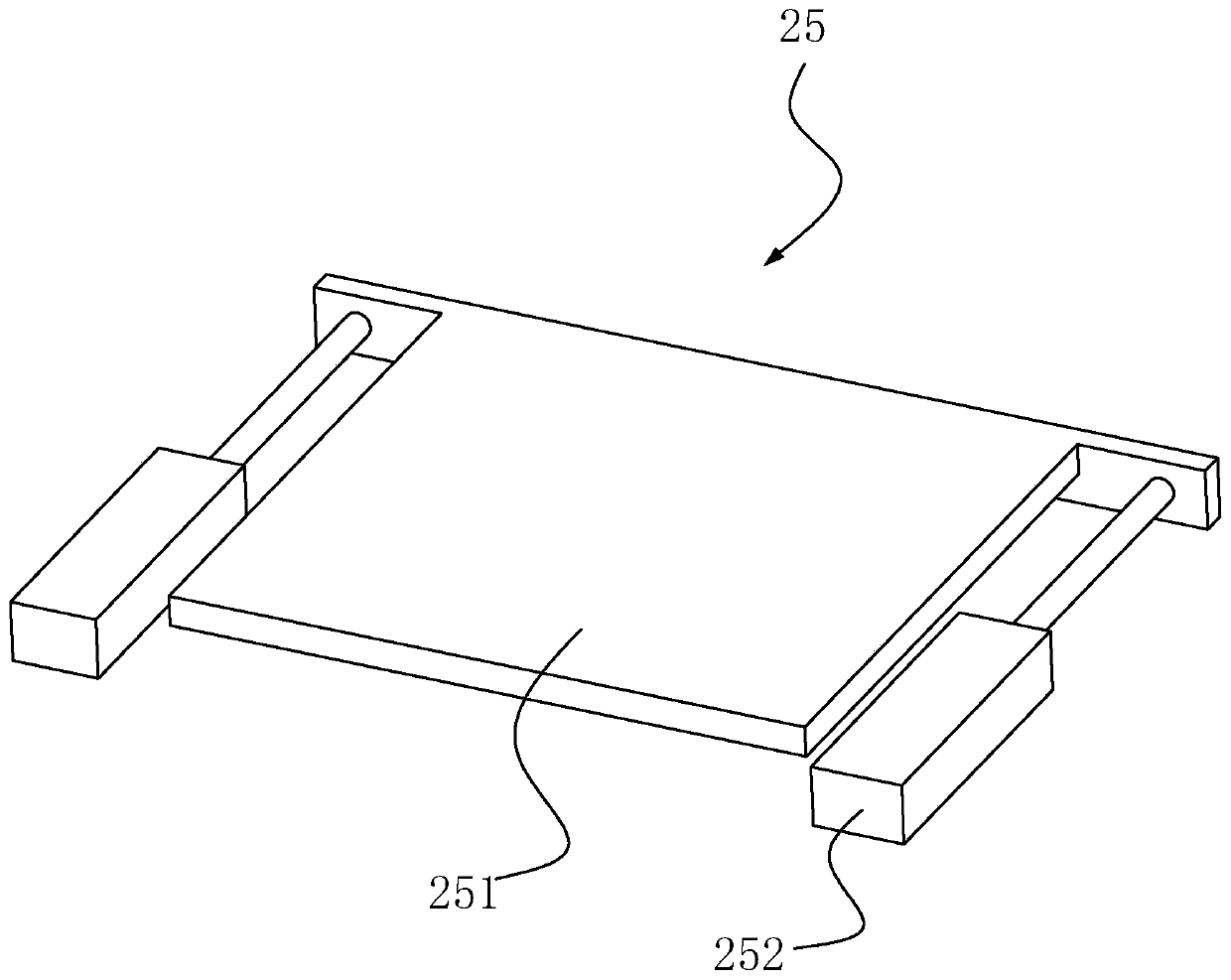

[0040] Embodiment 1: A kind of automatic screening and processing line of plastic products, refer to figure 1 , including a feeding transmission line 5, a water washing tank 2, a main transmission line 1, a drying device 3, a material identification device 4 and a sub-transmission line 6, the feed end of the sub-transmission line 6 is provided with a device for pushing the plastic products on the main transmission line 1 to the sub-transmission line 6 On the feeding assembly 7. The washing tank 2 is arranged above the feeding end of the main transmission line 1, and is used for washing and cleaning plastic products. The main transmission line 1 is used to transport the washed plastic products. The plastic products are dried by the drying device 3 and the plastic products are identified by the material identification device 4. Then, the feeding component 7 at the feeding end of the sub-transmission line 6 converts PVC and PET One of the plastic products in the material is push...

Embodiment 2

[0048] Embodiment 2: An automatic screening treatment method for plastic products, including the following method steps: Step S1: Put the plastic products into the washing tank 2 for washing and cleaning; the washing tank 2 is provided with a stirring paddle 27, and the plastic products are When cleaning, the stirring paddle 27 is driven to rotate by the drive motor 28; step S2: after cleaning the plastic product, dry the moisture attached to the surface of the plastic product through the drying device 3 during the transmission process; step S3: through the material identification The device 4 identifies the material of the plastic product during the transmission process, and pushes the plastic product of one material to the sub-transmission line 6 perpendicular to the transmission direction of the main transmission line 1 by controlling the feeding component 7 .

[0049] Before performing material identification on the plastic products, the plastic products are added into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com