A vulcanization mold for rubber tire manufacturing

A technology for vulcanizing molds and rubber tires, which is applied in the field of tire manufacturing and can solve problems such as increased workload, delamination, and limited tire pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Embodiments of the present invention will be described below with reference to the drawings. In this process, in order to ensure the clearness and convenience of the description, we may exaggerate the size of the width or constituent elements of the middle line.

[0026]In addition, the terms in the following are defined based on the functions in the present invention, and can be different depending on the user, the user's intention or convention. Therefore, these terms are defined based on all content of the present specification.

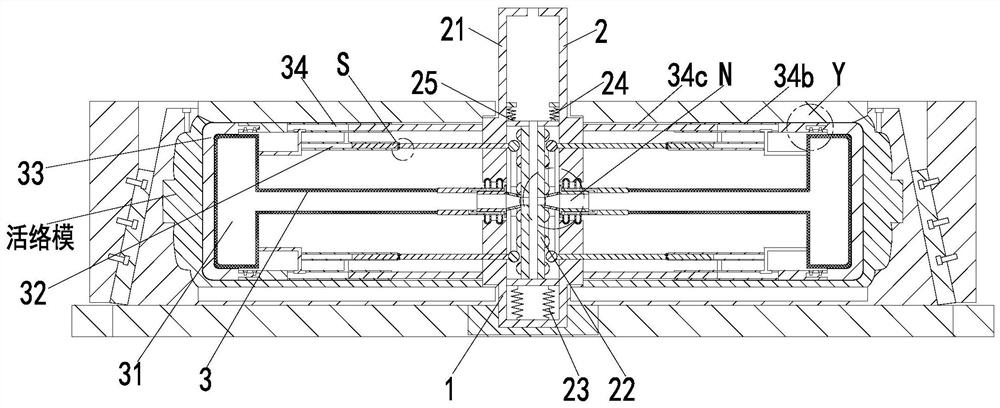

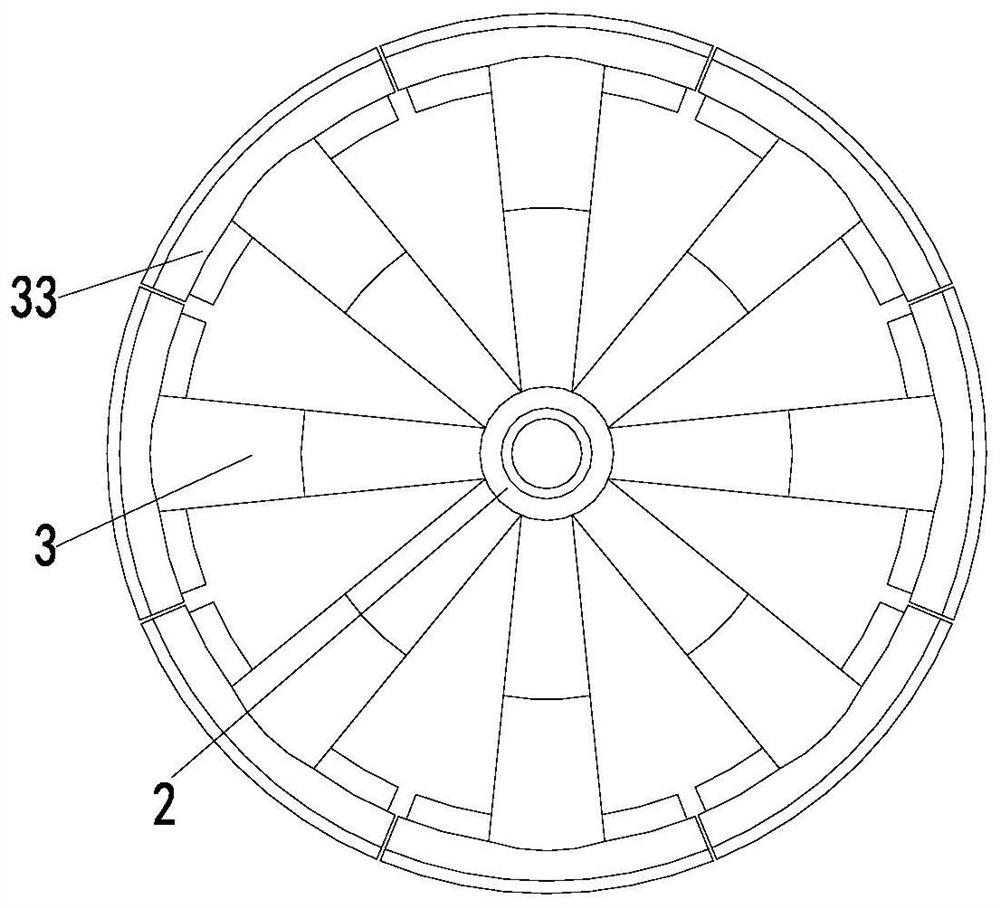

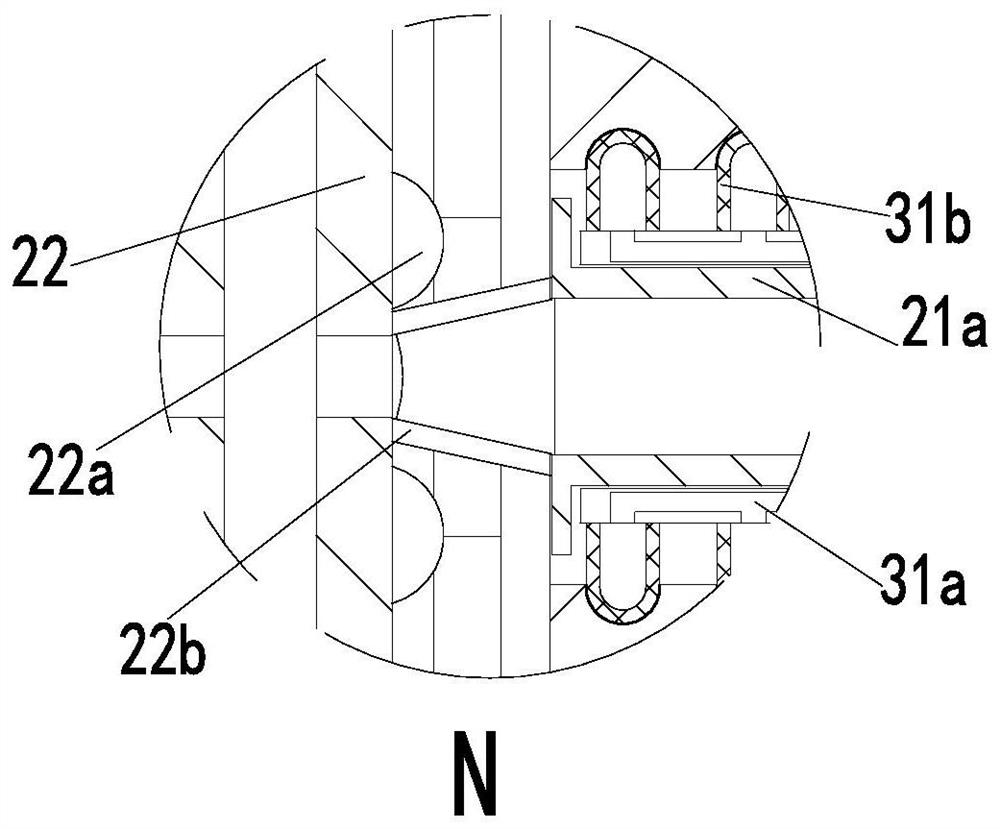

[0027]Such asFigure 1 to 5As shown, a rubber tire is manufactured by a sulfigation mold comprising a base 1, a ventilation module 2 and a compression module 3, and a ventilation module 2 is attached to the upper end of the base 1. There is a compression module 3 in the side of the vent module 2; wherein::

[0028]The ventilation module 2 includes a vent tube 21, an extruder 22, a torch spring 23, a retracting spring 24, and a returning block 25, and the ve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap