Charging gun assembly and charging method

A charging gun and assembly technology, applied in charging stations, electric vehicle charging technology, circuits, etc., can solve problems such as the loss of the charging gun assembly, and achieve the effect of ensuring safety and stability, reducing wear and tear, and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

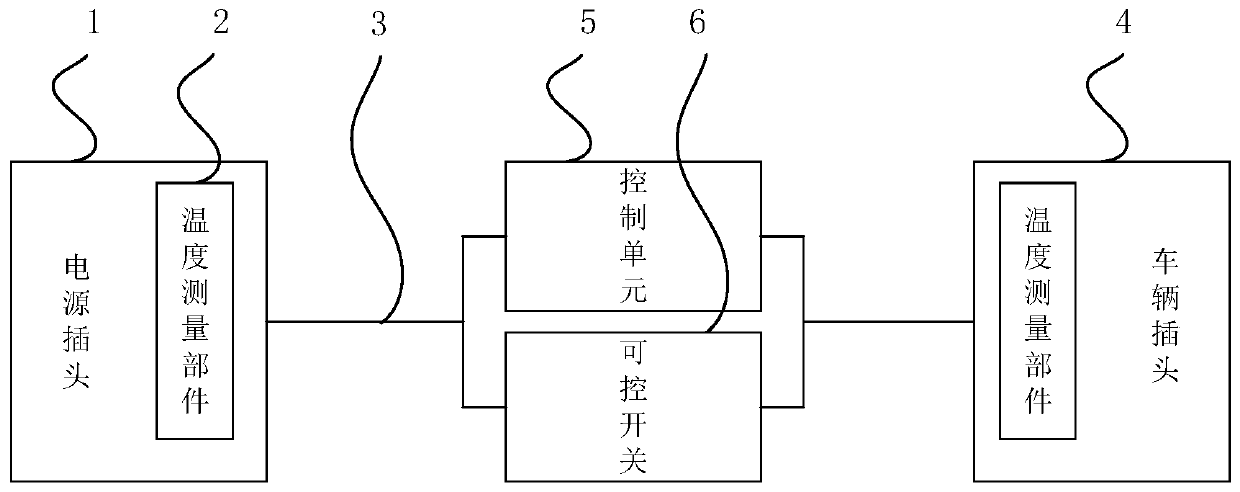

[0047] Specific implementation methods, such as figure 2 shown, including:

[0048] A control unit 5, arranged between the power plug 1 and the vehicle plug 4, and connected through the charging cable 3;

[0049] A controllable switch 6 is arranged on the charging cable 3;

[0050] Wherein, the temperature measuring component 2 is connected with the control unit 5, and a controllable switch 6 is arranged in the control unit 5.

[0051] Optionally, the controllable switch 6 may be connected to the control unit 5, and after the control unit 5 sends a charging signal, the controllable switch 6 is closed to start charging.

[0052] Specifically, the control unit 5 also includes a power supply control device connected to the vehicle control device.

[0053] Specifically, an equivalent resistance and an equivalent diode are connected between the power supply control device and the vehicle control device, wherein one end of the equivalent resistance is connected to the pulse widt...

Embodiment approach

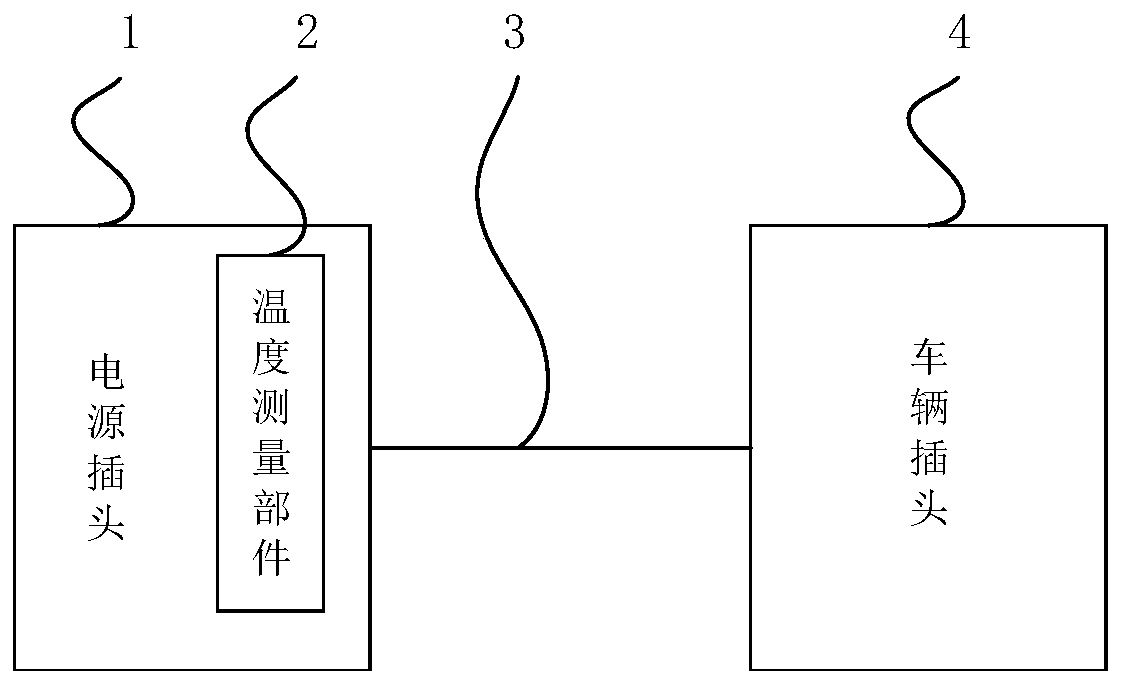

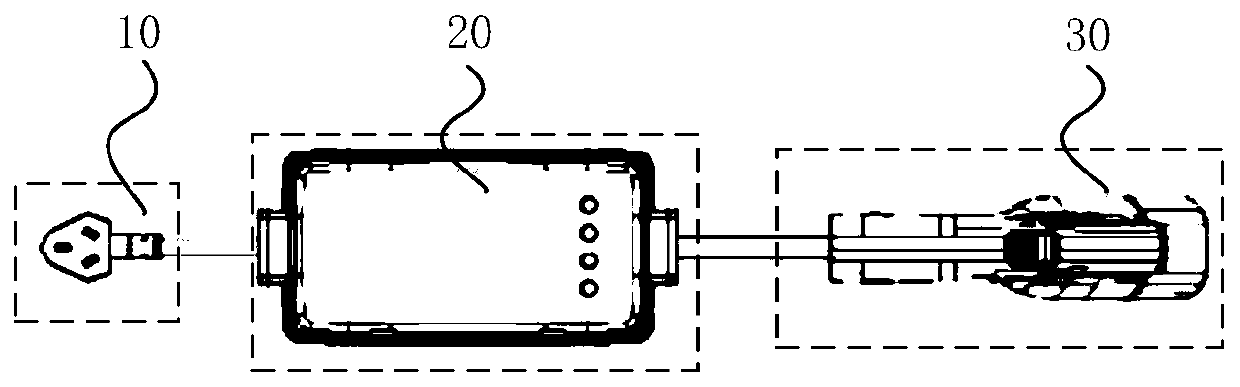

[0073] like image 3 As shown in -4, the charging gun assembly with three plugs and thermal protection is a charging connection device, which adopts charging mode two connection method B.

[0074] Its basic structure includes: three plugs 10 with thermal protection, an on-cable control box 20 , a charging cable 3 , and a vehicle plug 4 .

[0075] Specifically, the control charging method of the three-plug charging gun assembly with thermal protection includes:

[0076] The first step is to ensure the connection: insert the vehicle plug 4 into the vehicle socket, and insert the three plugs into the household AC socket;

[0077] The second step is to start charging: the power supply control device of the cable control box 20 maintains signal communication with the vehicle control device of the electric vehicle, and the electric vehicle notifies the cable control box 20 to start charging. The control box 20 on the cable controls the controllable switch 6, pulls K1 and K2 into c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com