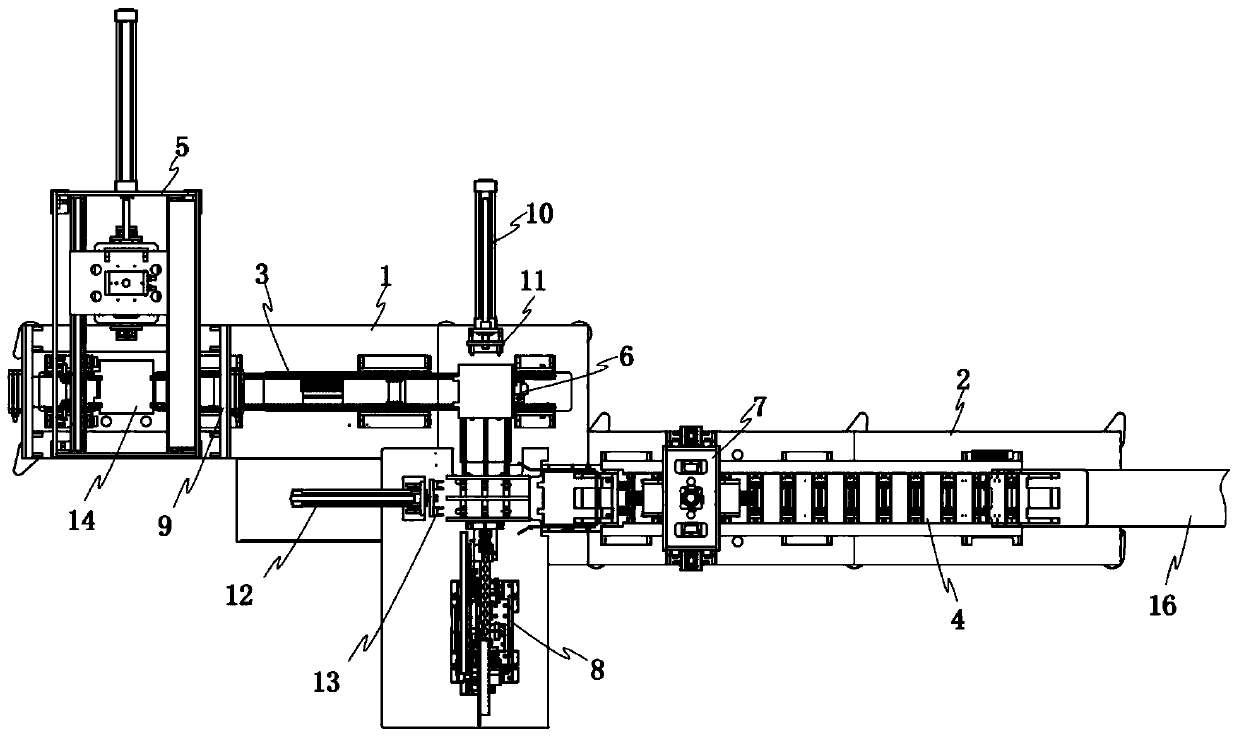

Sorting and coding conveyor for stainless steel plates

A stainless steel plate and conveyor technology, applied in packaging and other directions, can solve the problems of stainless steel plate cutting the hands of workers, poor packing quality, and low efficiency, and achieve the effect of ensuring the quality of packing and improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

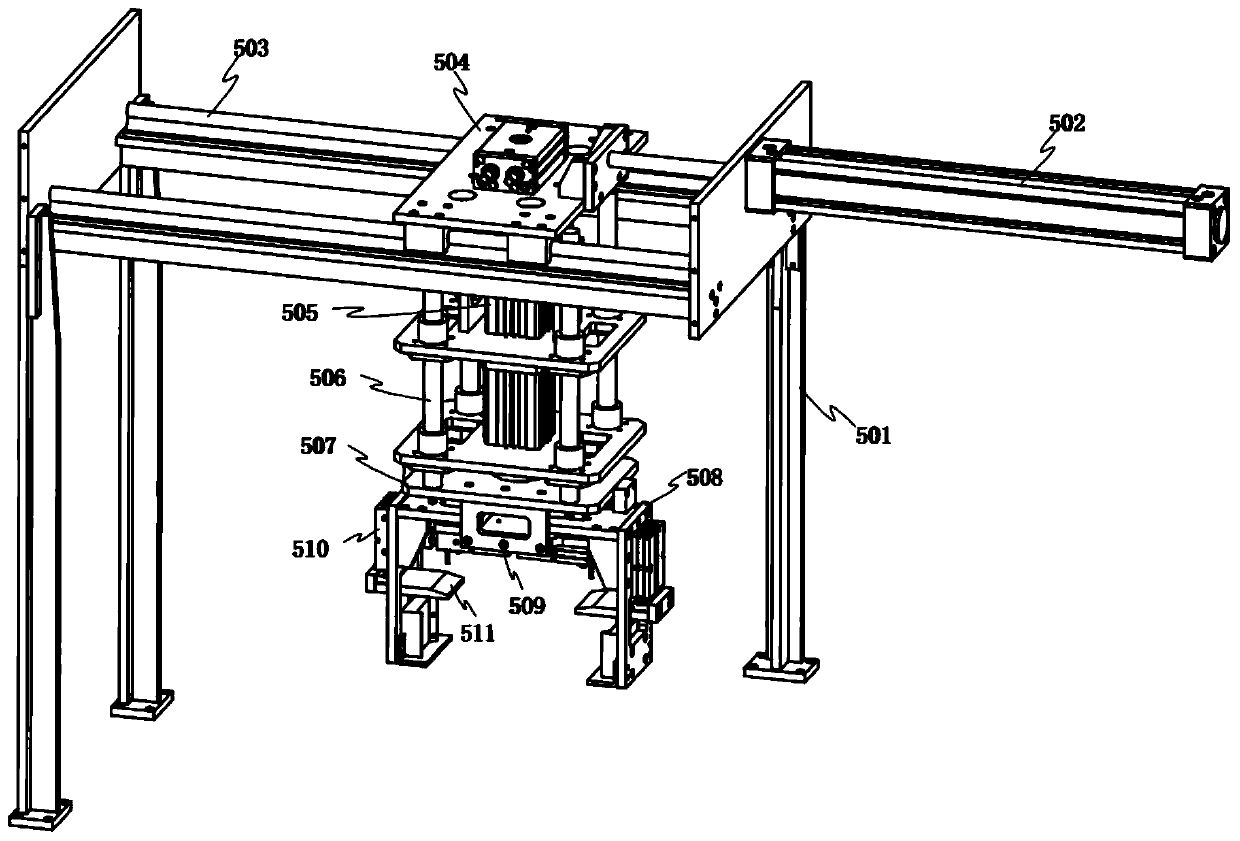

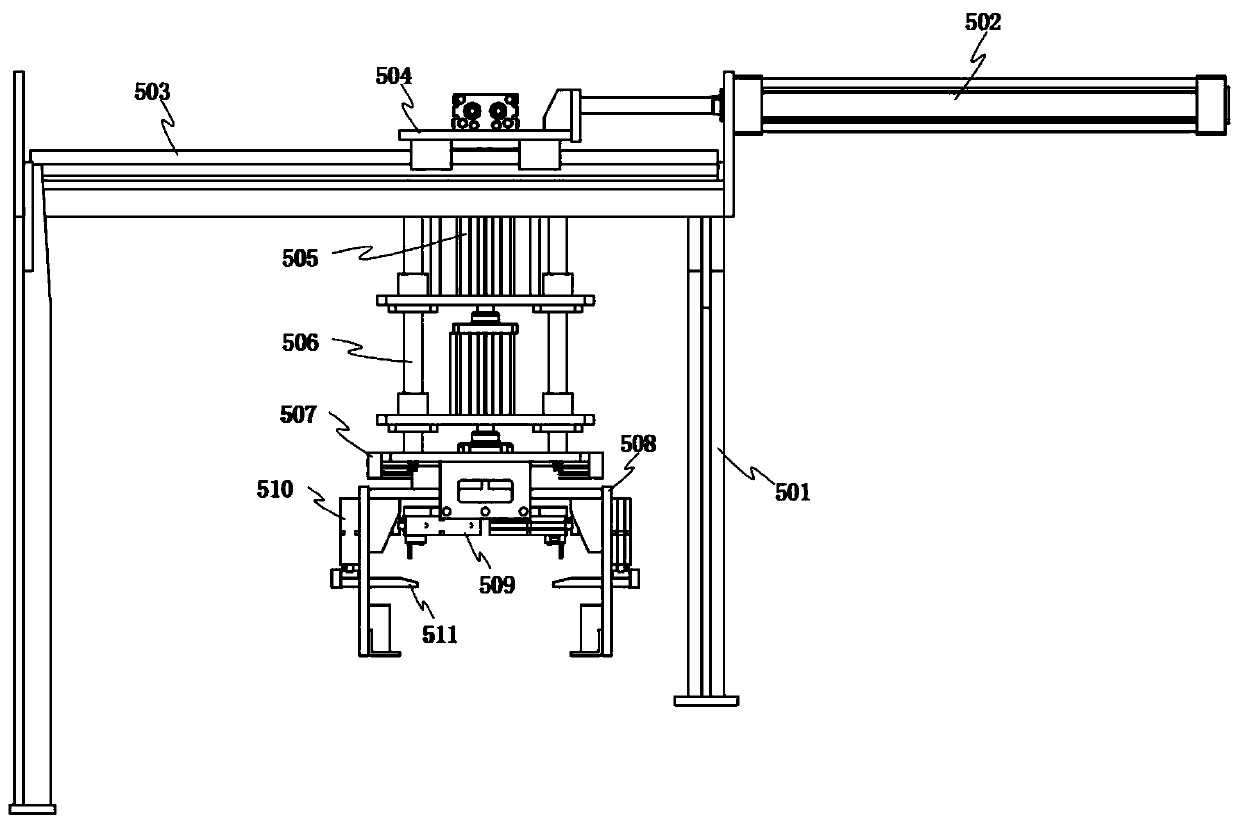

[0033] When the conveyor is in use, the horizontal drive cylinder 502 of the clamping input mechanism 5 first drives the installation slide I504 to move along the parallel slide rail I503 to the top of the stack of stainless steel plates to be sorted and coded, and then starts the lifting drive cylinder I505. The driving cylinder I505 drives the clamping plate frame 508 to move down along the vertical guide rod 506, and then starts the horizontal telescopic cylinder 509 and the vertical telescopic cylinder 510 on the clamping plate frame 508, thereby driving the clamping plate 511 to stack the stainless steel plates Clamping, then driven by the horizontal drive cylinder 502 and lifting drive cylinder I 505 to drive the clamping plate frame 508 and the clamped stainless steel plate stack to the lifting plate frame 902 of the rotary turning mechanism 9, and then driven by the horizontal telescopic cylinder 509 The clamping plate frame 508 releases the stack of stainless steel pla...

Embodiment 2

[0035] When the first conveyor belt 3 transfers the stack of stainless steel plates to the position of the jacking mechanism 6, the lifting drive cylinder III601 of the jacking mechanism 6 is activated, and the lifting drive cylinder III601 drives the movable jacking bracket 603 to lift the first conveyor belt 3 The stainless steel plate stack is lifted up, and then the ejection block I11 is driven by the push-out cylinder 10 to move the stainless steel plate stack along the surface of the movable jacking bracket 603 to the lower part of the coding mechanism 8, and then the driving motor 805 of the coding mechanism 8 is detoured Through the belt drive, the recovery runner 806 and the guide pulley 807 are driven to rotate, so that the identification code tape 809 on the rotating hanging plate 808 is rotated and output loaded with the identification code tape body, and the identification code tape body is along the guide pulley 807 and the entrainment plate 813 runs, and starts t...

Embodiment 3

[0037] Start the side clamping cylinder 702 and the positive clamping cylinder 708 of the finishing mechanism 7, and the side clamping plate 703 is driven by the side clamping cylinder 702 to clamp the end faces on both sides of the stainless steel plate, and the positive clamping cylinder 708 drives the front side through the hinged rod frame 709 The clamping plate 710 clamps the front and rear end surfaces of the stack of stainless steel plates, and then starts the pressing cylinder 707 and the straightening driving cylinder 704 of the finishing mechanism 7, and the pressing cylinder 707 drives the top finishing groove block 711 to move down, and the top finishing groove block The notch part of 711 is matched with the raised part of the end surface of the stainless steel plate stack, and the straightening drive cylinder 704 drives the side finishing rod frame 706 through the linkage rod 705 to clamp both sides of the stainless steel plate stack, and the stainless steel plate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com