Fruit peeling machine

A peeling machine, fruit technology, applied in the peeling of vegetables or fruits, food science, application, etc., to achieve the effect of improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

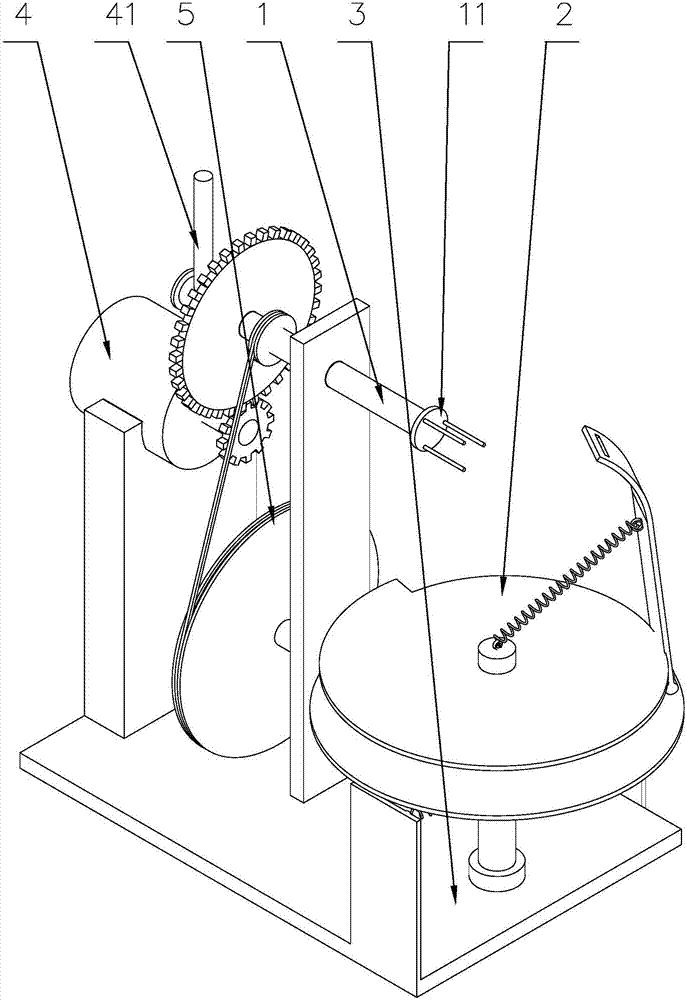

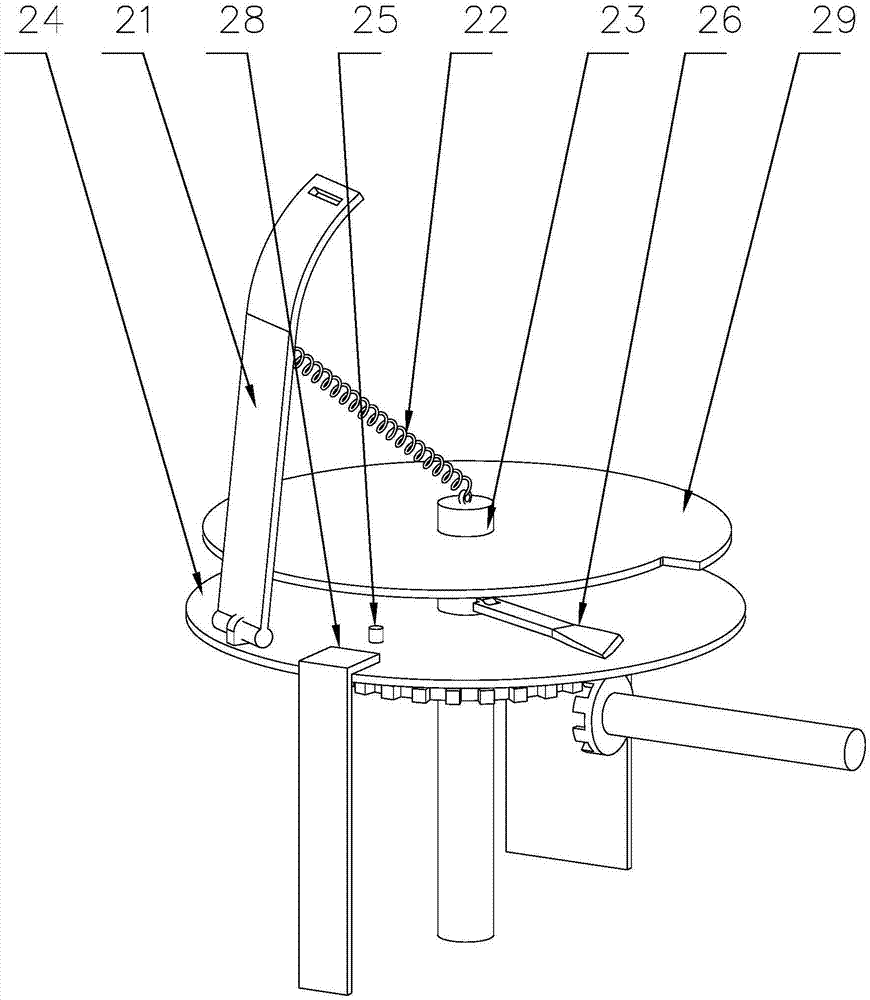

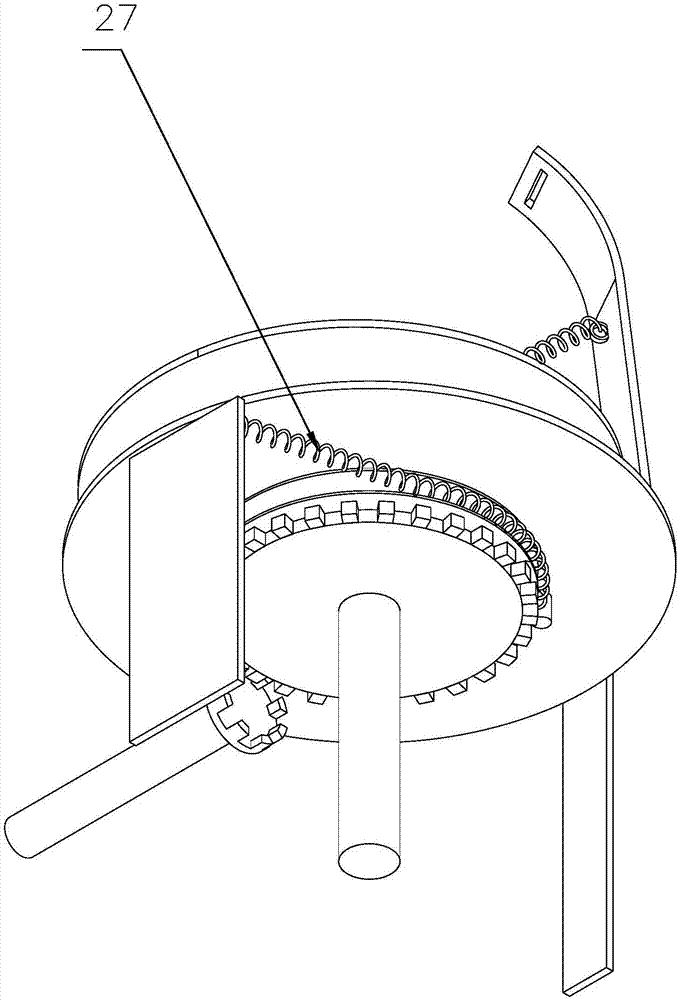

[0018] The fruit peeling machine of the present invention is a mechanical device similar to a lathe, comprising a main shaft 1, a rotary knife device 2 and a base 3, one end of the main shaft 1 is provided with a fixed fork 11 for holding fruit, and the other end is connected to a driving device 4, so The main shaft 1 is connected to the rotary tool device 2 through the transmission structure 5, and the tool 21 is hinged on the rotary tool device 2, and the tool 21 is pulled inward by the extension spring I22. The rotary knife device 2 of knife reset. After starting the machine, the main shaft 1 drives the fruit and the cutter 21 to rotate together. During the rotation of the fruit, the cutter 21 makes a circular motion in the horizontal direction, and is close to the fruit under the tension of the extension spring I22, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com