Device for achieving lifting and overturning of large workpiece through gear and rack

A technology for racks and pinions and large workpieces, applied in the field of machining, can solve problems such as shaking, damage to peripheral equipment, damage to workpieces, etc., to improve work efficiency and safety, reduce health hazards, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

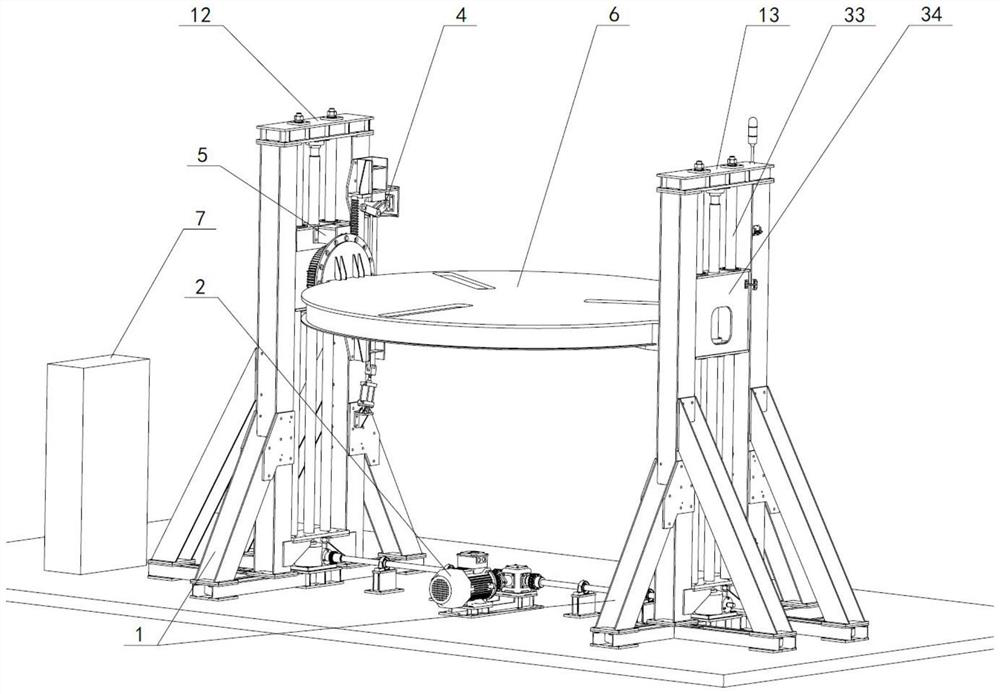

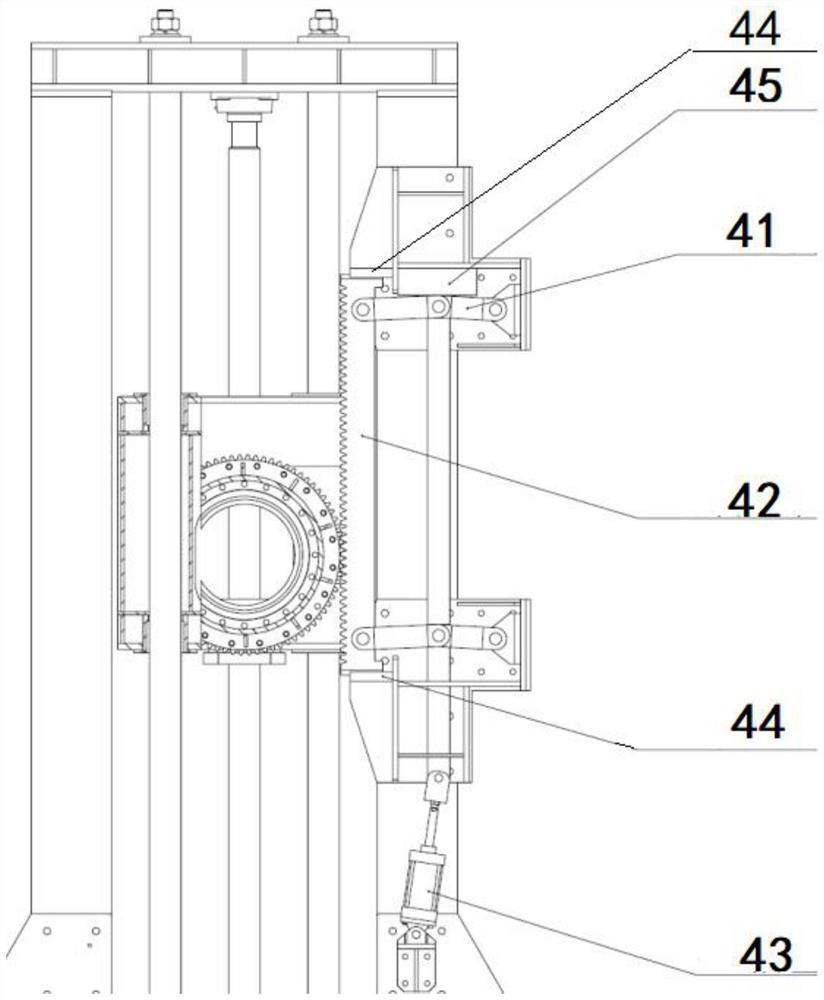

[0049] Such as figure 1 As shown, a device that utilizes a rack and pinion to realize the lifting and turning of a large workpiece includes a frame 1, a drive system 2, a lifting mechanism 3, a turning mechanism 4, a locking mechanism 5, a turning platform 6 and a PLC control system 7, and the frame 1 Respectively by the first support frame 12 and the second support frame 13, the drive system 2 is arranged at the bottom of the frame 1, the number of lifting mechanisms 3 has two groups, respectively arranged on the first support frame 12 and the second support frame 13, The overturning mechanism 4 is arranged on the first supporting frame 12, the overturning platform 6 is connected to the slider 34 through the slewing bearing 61, and the PLC control system 7 is electrically connected with the drive system 2, the overturning mechanism 4 and the locking mechanism 5 respectively.

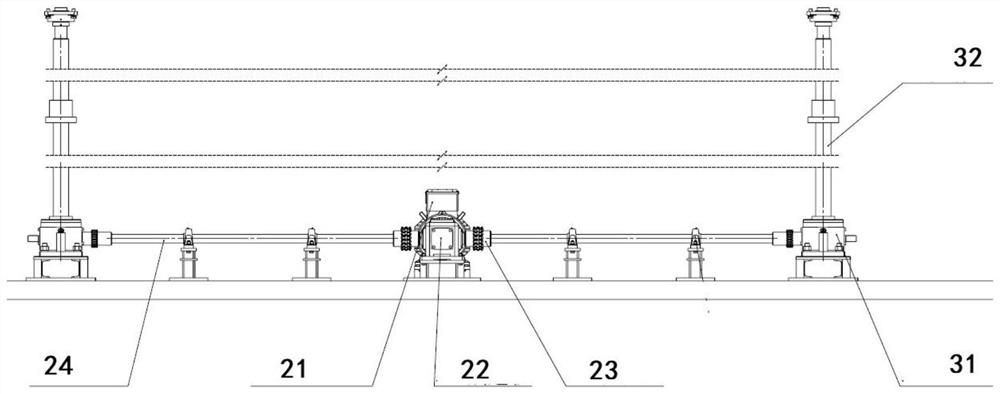

[0050] Such as figure 2 As shown, the drive system 2 includes a motor 21 and a speed reducer 22 co...

Embodiment 2

[0075] On the basis of Embodiment 1, wherein the driving system 2 can be replaced by a hydraulic system, it is not limited to a power supply method.

Embodiment 3

[0077] On the basis of Embodiment 1, the number of lifting mechanisms 3 can be no less than two groups of even groups, and are symmetrically distributed on the first support frame 12 and the second support frame 13, which can be increased according to actual production work, so that It is more stable and has a larger load when it operates (rising or turning).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com