Axial positioning support structure for round timber processing, and application method thereof

A technology of axial positioning and bracket structure, which is applied in the field of plate processing, can solve problems such as difficult control, eccentricity in the rotation process, and laborious hand-cranking process, so as to improve work efficiency and safety, improve production efficiency, and ensure clamping effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

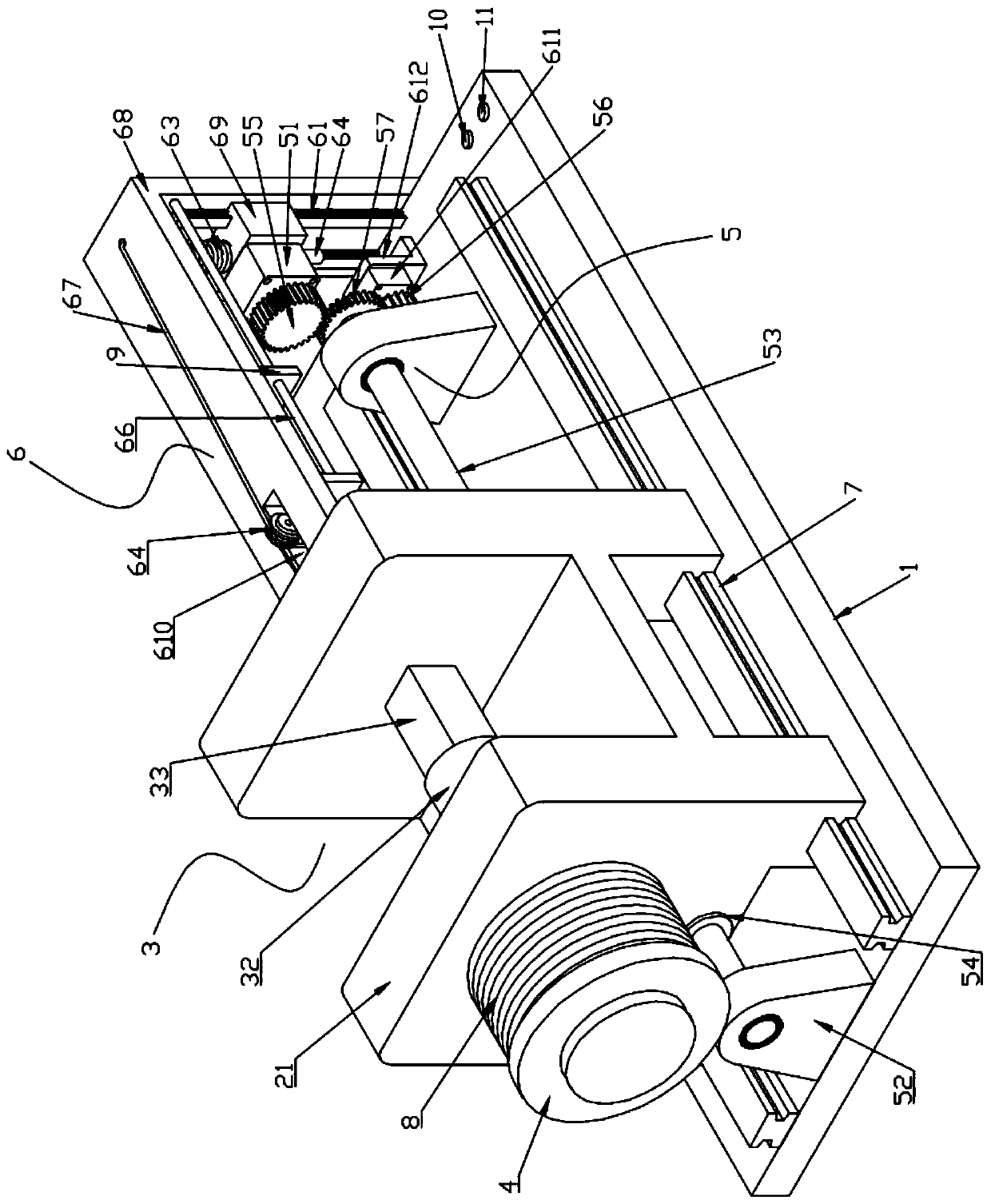

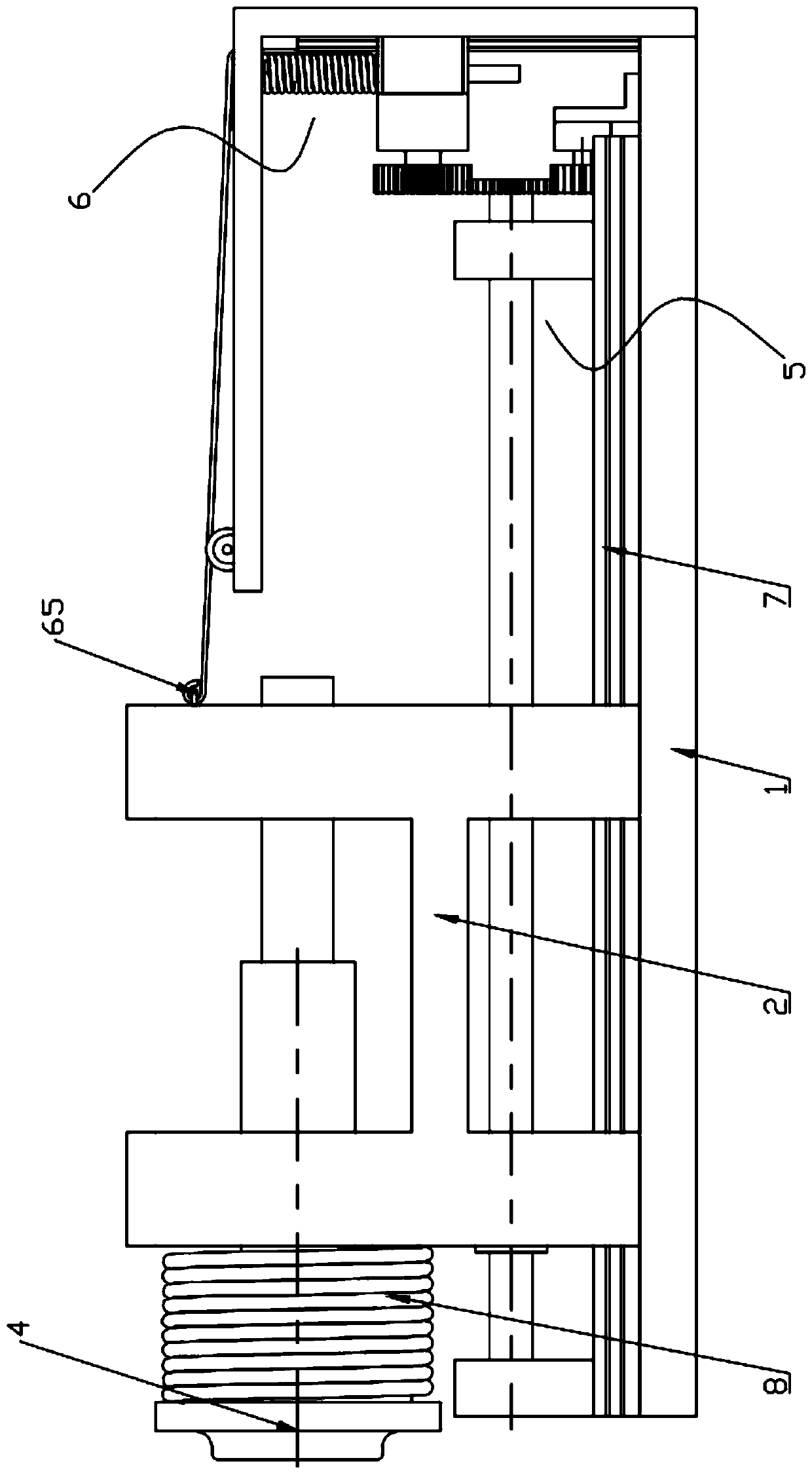

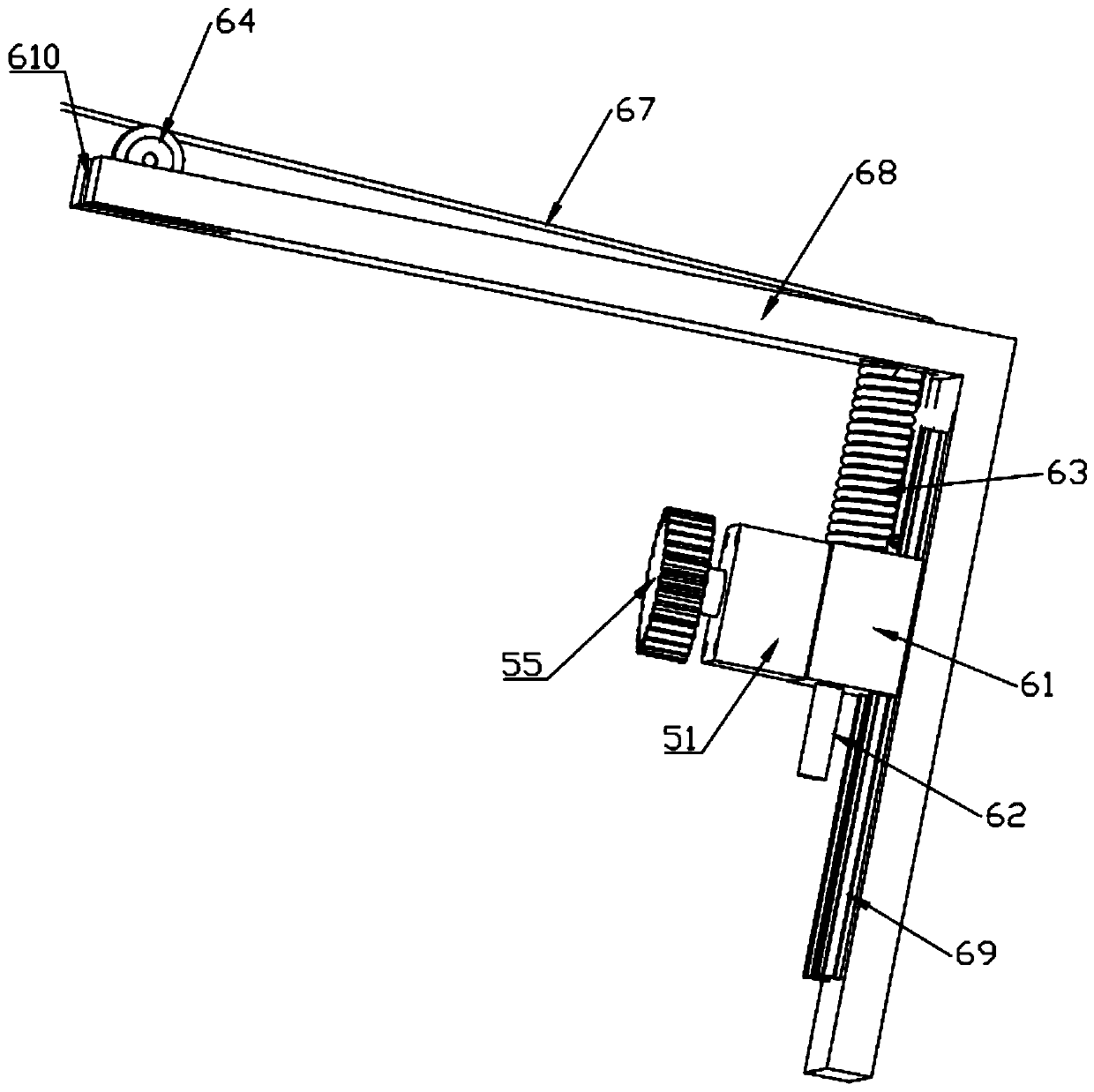

[0030] Such as Figure 1 to Figure 8 As shown, an axial positioning bracket structure for round wood processing includes a base plate 1, a movable frame 2, a thimble assembly 3, a quick release top block 4, a drive assembly 5 and an automatic locking assembly 6, and the movable frame 2 is slidably connected to On the slide rail 7 on the top surface of the substrate 1 and can move horizontally along the length direction of the substrate 1 by means of the drive assembly 5, the thimble assembly 3 is slidably connected to the movable frame 2 and the thimble assembly 3 is also A spring one 8 is sleeved, and the spring one 8 is located at the front end of the movable frame 2. The quick release top block 4 is detachably connected to the front end of the thimble assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com