LED element packing detector

A detection machine and packaging technology, which is applied in the direction of packaging, packaging objects under special gas conditions, transportation packaging, etc., can solve the problems of low production efficiency, integration, and poor anti-pressure effect, so as to improve the anti-pressure effect and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

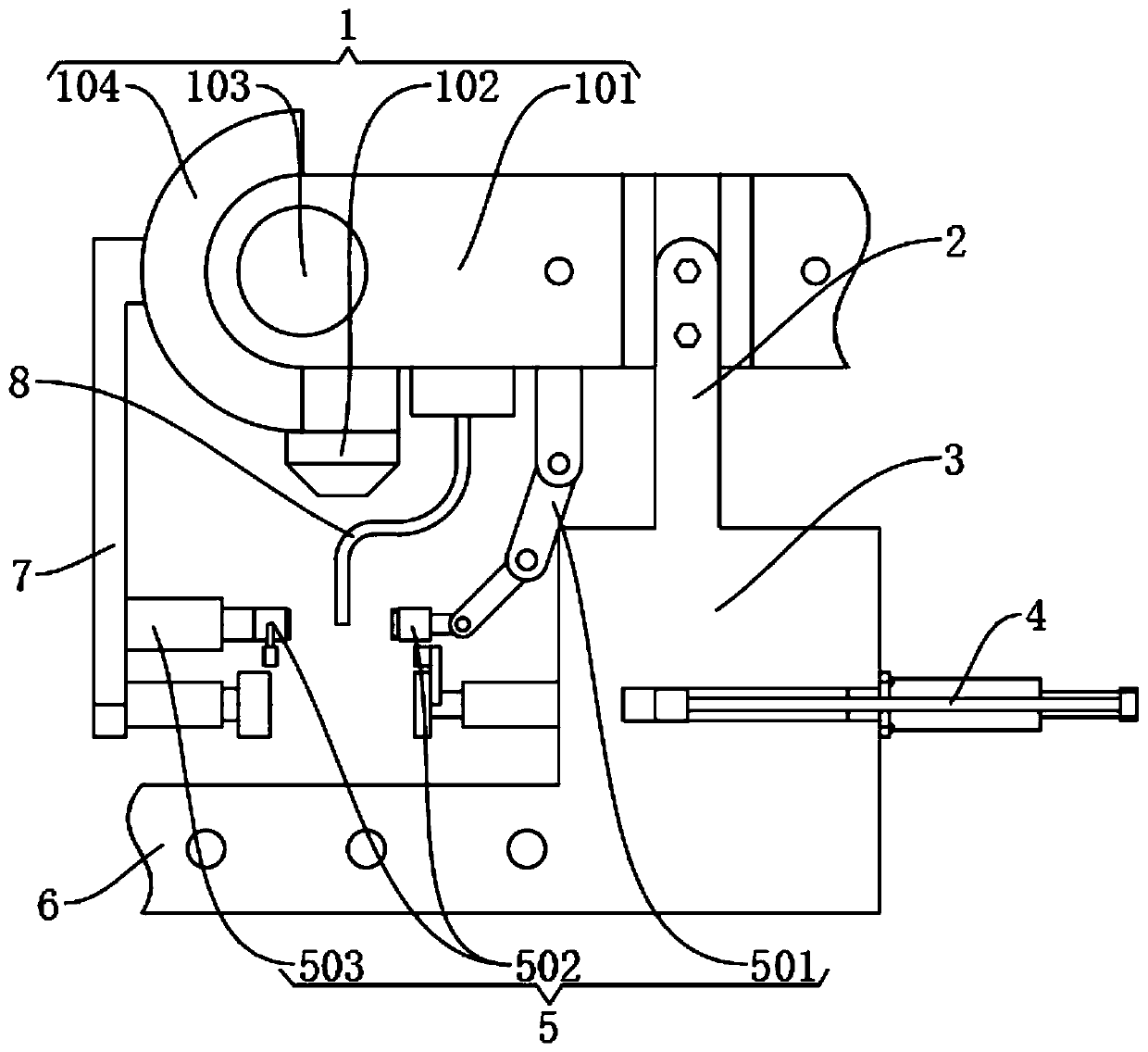

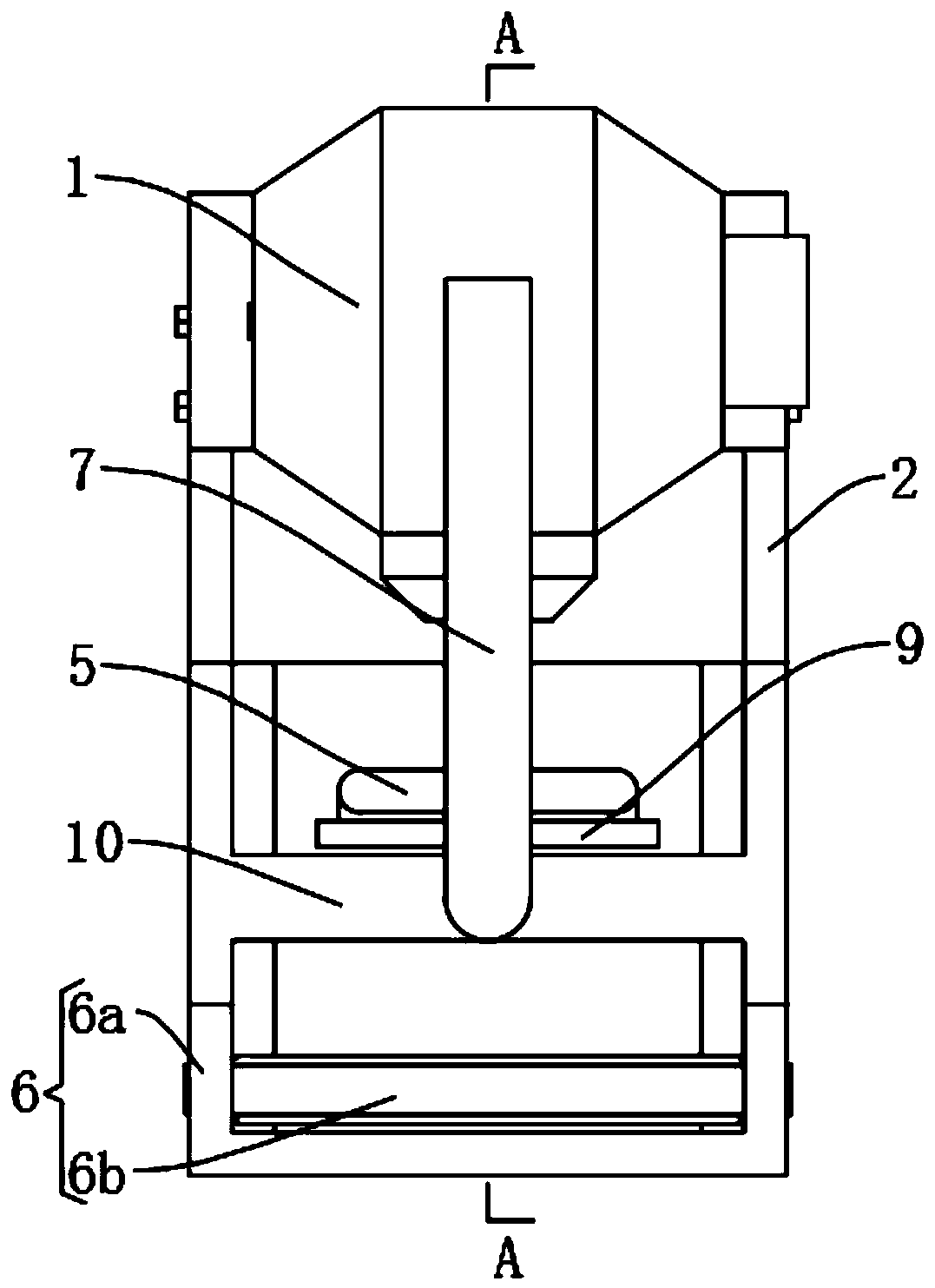

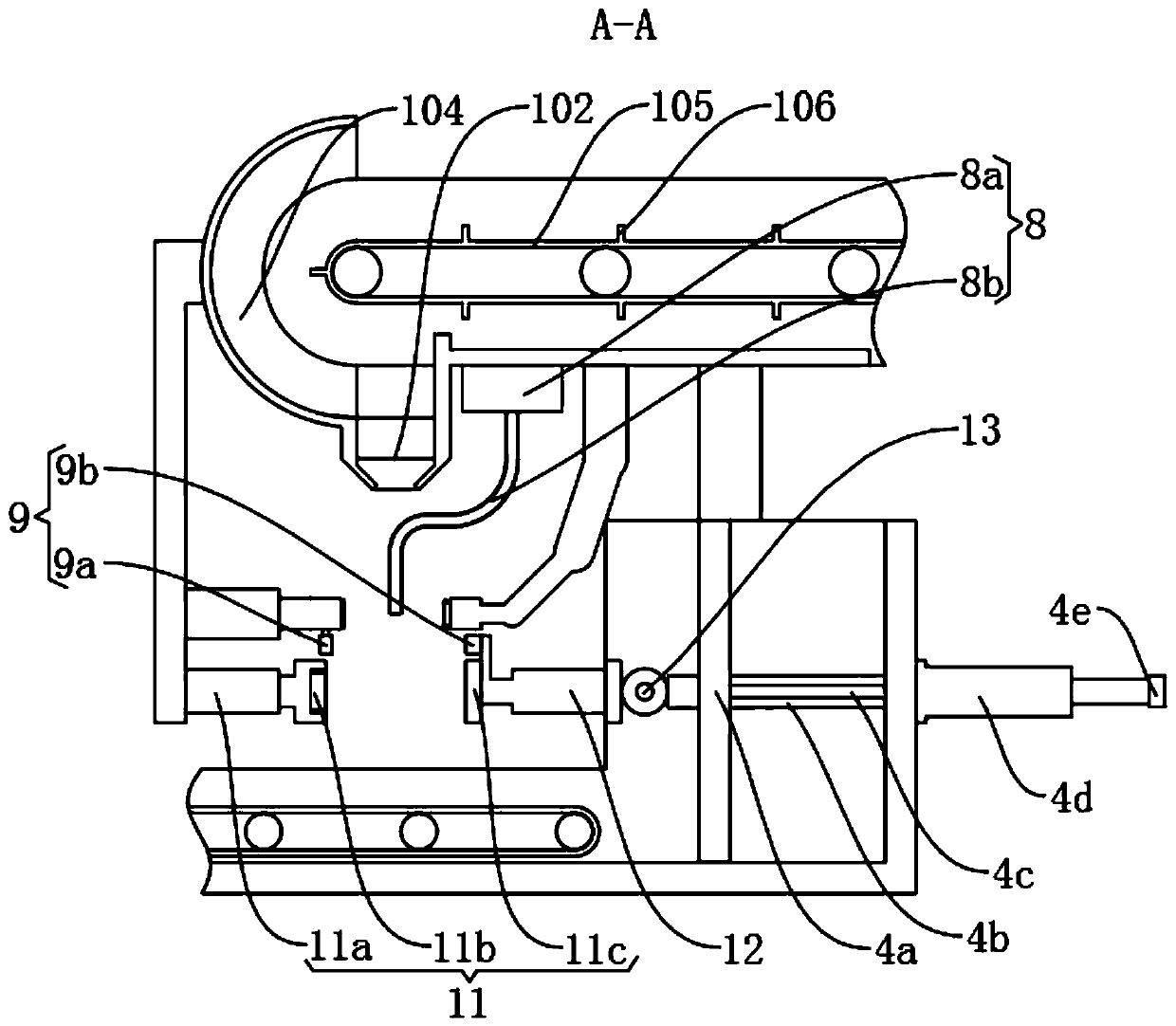

[0052] see Figure 1-Figure 5 As shown, a LED component packaging inspection machine of the present invention includes a feed transmission part 1, a discharge transmission part 6, a bag supply box 3, a bag pressing part 4, a bag opening part 5, an inflatable part 8, a bag sealing part 9, And detection component 11 etc.

[0053] Wherein, a bag supply box 3 for placing packaging bags is arranged under the feeding transmission part 1, and a bag pressing part 4 for compressing and fixing the packaging bags is arranged in the bag supply box 3, and the feeding transmission part 1 is close to its outlet. An inflatable part 8 for inflating the packaging bag is arranged at the position of the material opening.

[0054] The bag opening part 5 is arranged below the position of the discharge port of the feeding conveying part 1, and the bag sealing part 9 for sealing the opening of the packaging bag is arranged under the bag opening part 5, and the bag sealing part 9 is arranged for seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com