A kind of desulfurization method of acid process lithium slag powder and application of desulfurization lithium slag powder

A lithium slag powder, acid method technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of resource waste, environmental pollution, etc., to save resources, protect the environment, and reduce concrete cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0035] According to the mass percentage, the composition of acid lithium slag powder is: SiO 2 55.8%, Al 2 o 3 25.2%, SO 3 10%, CaO7%, Fe 2 o 3 0.7%, K 2 O 0.8% and unavoidable impurities;

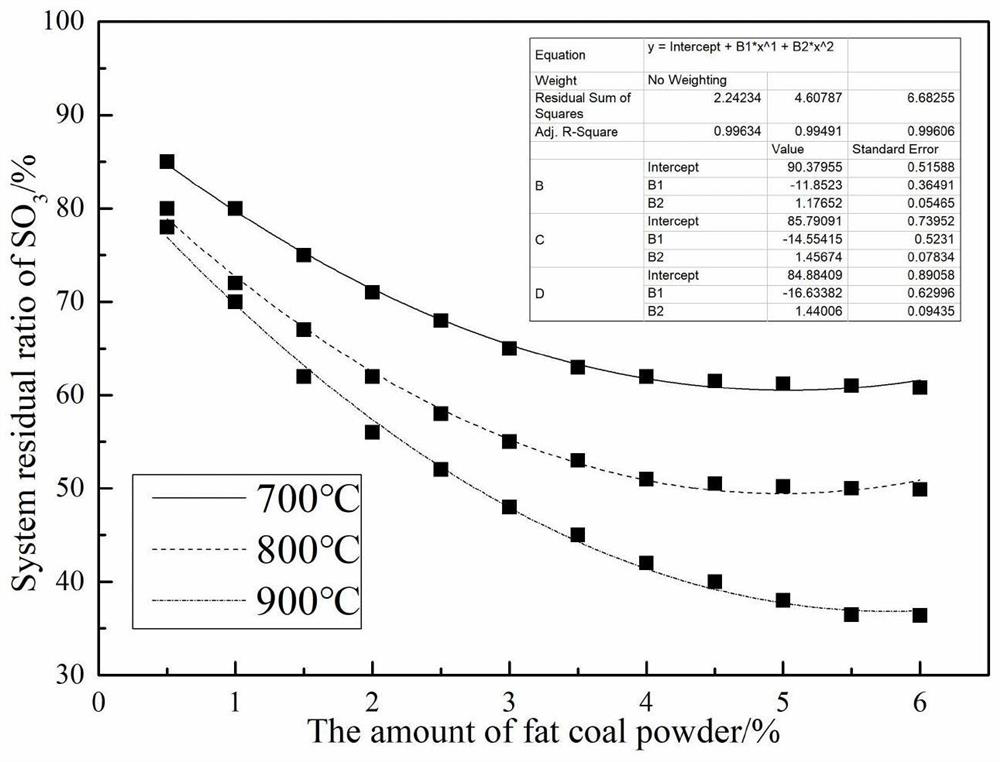

[0036] The acid method lithium slag powder and the fat coal powder are mixed (the mass ratio of the fat coal powder to the acid method lithium slag powder is m%, m=0.5, 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5 and 6) Put it in a muffle furnace, raise the temperature to 700°C at a rate of 10°C / min, keep it warm for 120min, and cool it down to room temperature naturally to obtain desulfurized lithium slag powder;

[0037] Test the sulfur content (sulfur trioxide content) of described desulfurization lithium slag powder, test result is as shown in table 1:

[0038] Table 1 The sulfur content and desulfurization rate of the desulfurized lithium slag powder obtained under different amounts of fat coal powder in Examples 1-12

[0039] Example m Sulfur content (%) Desulfuriza...

Embodiment 13~24

[0041] According to the mass percentage, the composition of acid lithium slag powder is: SiO 2 55.8%, Al 2 o 3 25.2%, SO 3 10%, CaO7%, Fe 2 o 3 0.7%, K 2 O 0.8% and unavoidable impurities;

[0042]The acid method lithium slag powder and the fat coal powder are mixed (the mass ratio of the fat coal powder to the acid method lithium slag powder is m%, m=0.5, 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5 and 6) Put it in a muffle furnace, raise the temperature to 800°C at a rate of 10°C / min, keep it warm for 120min, and cool it down to room temperature naturally to obtain desulfurized lithium slag powder;

[0043] Test the sulfur content (sulfur trioxide content) of described desulfurization lithium slag powder, test result is as shown in table 2:

[0044] Table 2 The sulfur content and desulfurization rate of the desulfurized lithium slag powder obtained under different amounts of fat coal powder in Examples 13-24

[0045] Example m Sulfur content (%) Desulfuriza...

Embodiment 25~36

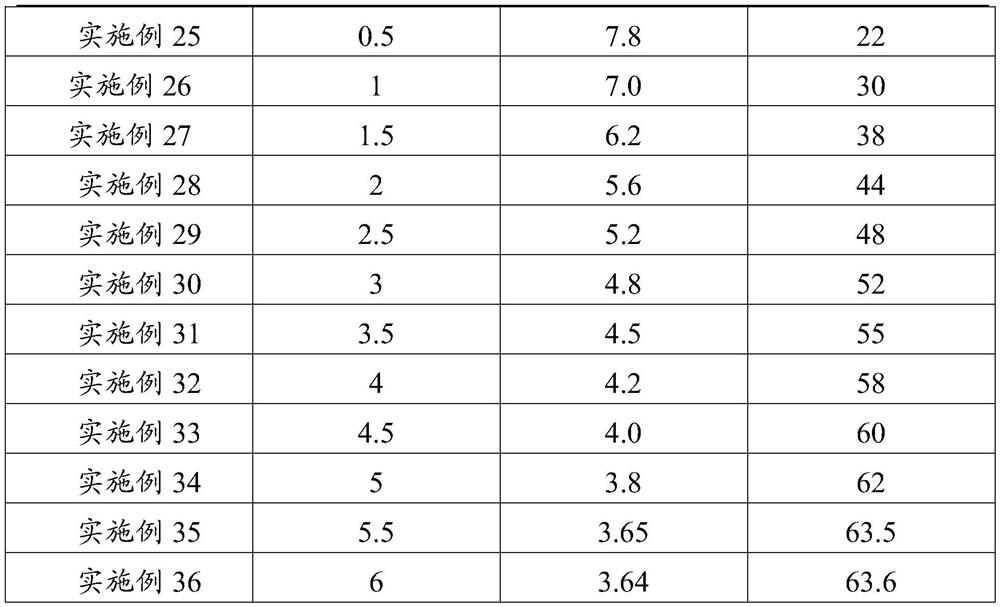

[0047] According to the mass percentage, the composition of acid lithium slag powder is: SiO 2 55.8%, Al 2 o 3 25.2%, SO 3 10%, CaO7%, Fe 2 o 3 0.7%, K 2 O 0.8% and unavoidable impurities;

[0048] The acid method lithium slag powder and the fat coal powder are mixed (the mass ratio of the fat coal powder to the acid method lithium slag powder is m%, m=0.5, 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5 and 6) Put it in a muffle furnace, raise the temperature to 900°C at a rate of 10°C / min, keep it warm for 120min, and cool it down to room temperature naturally to obtain desulfurized lithium slag powder;

[0049] Test the sulfur content (sulfur trioxide content) of described desulfurization lithium slag powder, test result is as shown in table 3:

[0050] Table 3 The sulfur content and desulfurization rate of the desulfurized lithium slag powder obtained under different amounts of fat coal powder in Examples 25-36

[0051]

[0052]

[0053] The desulfurization rates of E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com