Method for improving grain size of additive manufacturing

A technology of additive manufacturing and grain size, which is applied in the field of improving the grain size of additive manufacturing, and can solve problems such as the influence of mechanical properties of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

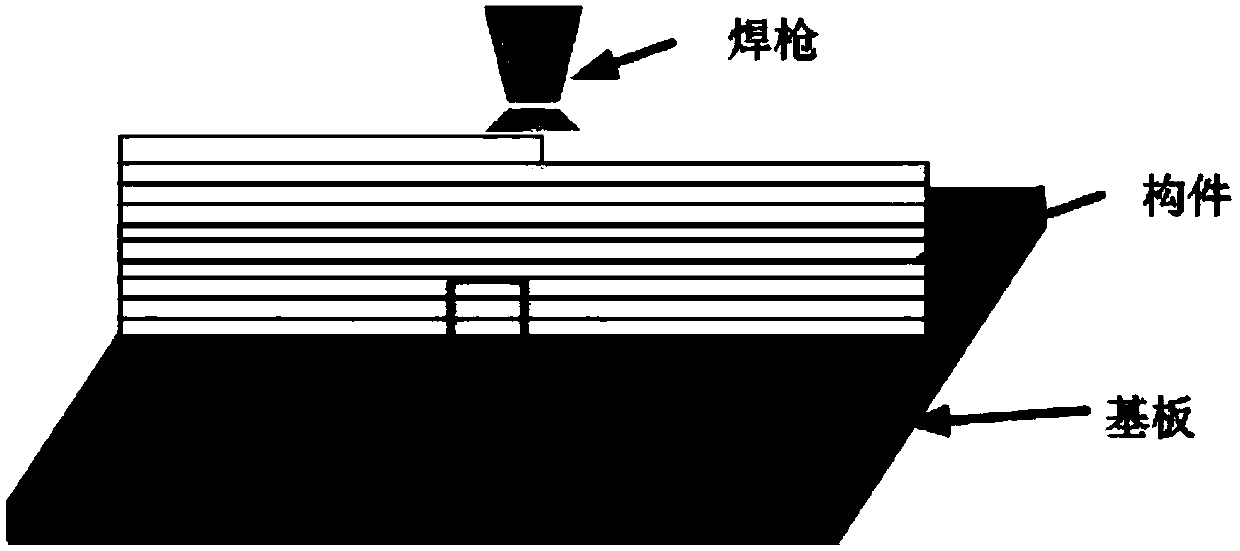

[0026] Further illustrate technical scheme of the present invention below in conjunction with specific embodiment:

[0027] The metal arc additive manufacturing test substrate involved in the present invention is aluminum alloy 6061, the size of the substrate is 300×150×4mm, and the welding wire is ER4043. The direct current cold metal transfer technology (cold metal transfer, CMT) was used to conduct the experiment of arc additive manufacturing of aluminum alloy. The CMT welder used for the test is the CMT Advanced 4000 welder from Fronius.

[0028] Table 1 Material Composition List

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com