Wallboard mounting robot

A robot and wallboard technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of high strength, low construction efficiency and poor construction quality of wallboard installation, and achieve increased stability and anti-overturning. capacity, large carrying capacity, and the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

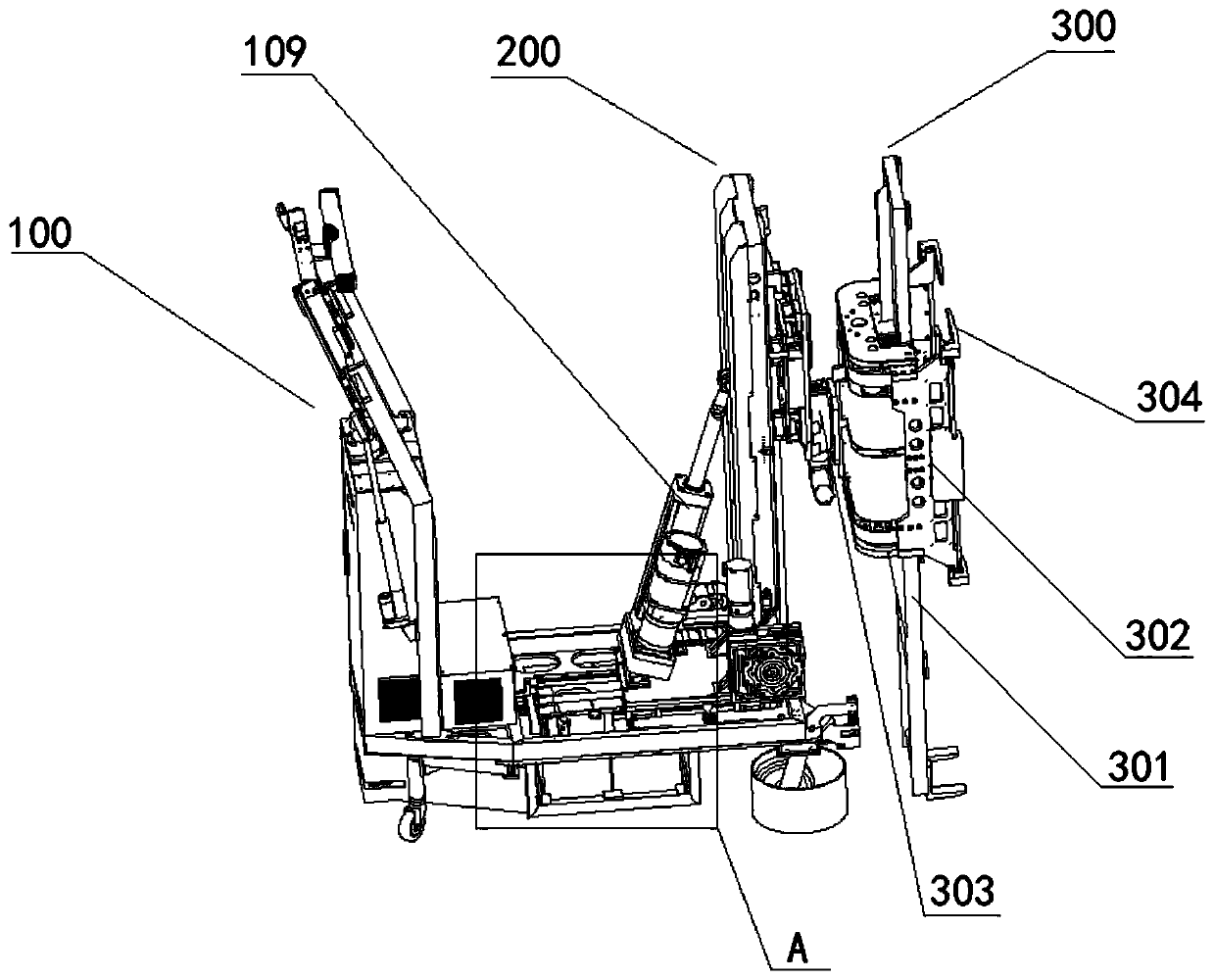

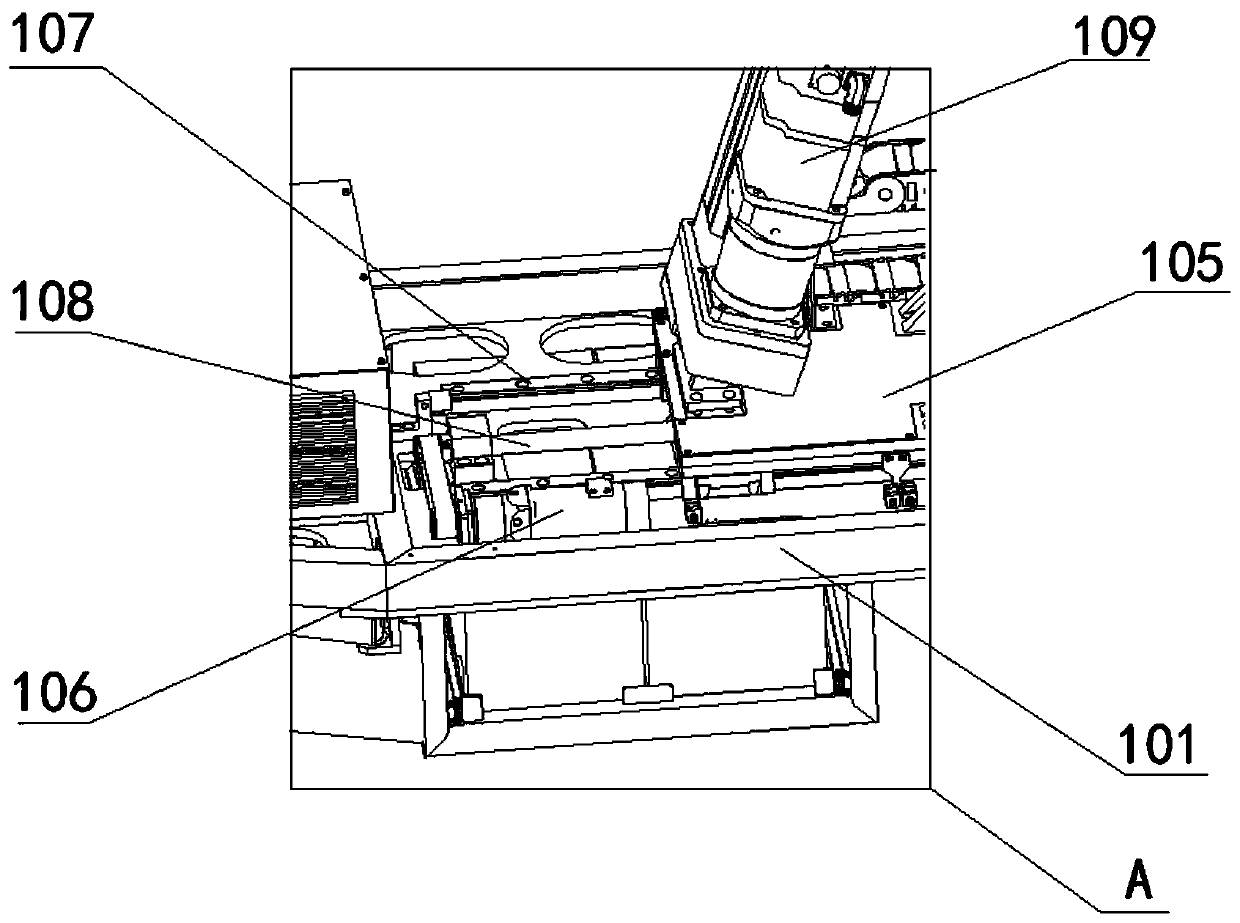

[0032] see figure 1 , the present embodiment provides a wall panel installation robot, comprising a body device 100, a translation jacking device 200 and a swing jaw device 300, the translation jacking device 200 is arranged on the body device 100, and is hinged with the body device 100, and the swing clamp The claw device 300 is arranged on the translation jacking device 200 and is rotatably connected with the translation jacking device 200 .

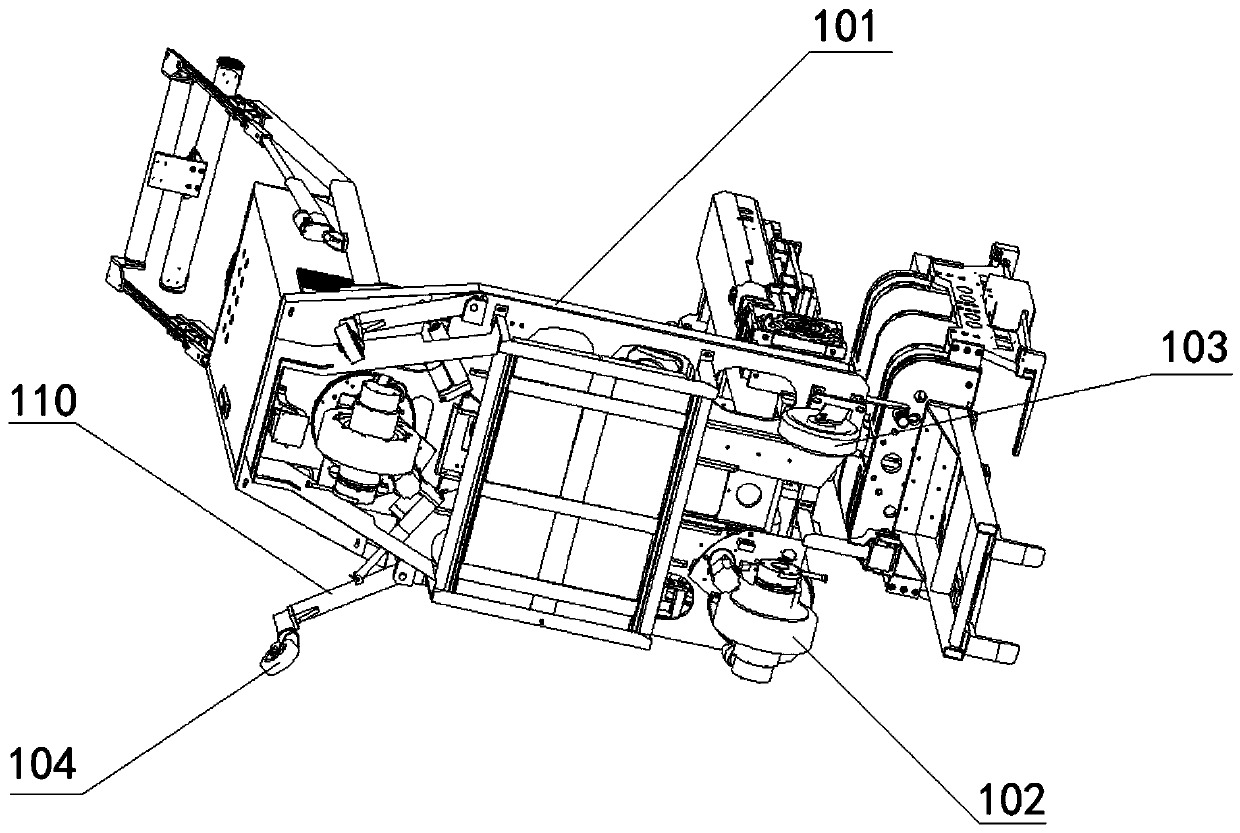

[0033]The body device 100 includes a chassis frame 101, under which two steering wheels 102, a driven wheel 103 and two auxiliary wheels 104 are arranged, and the two steering wheels 102 are arranged at intervals one after the other, and the auxiliary wheels 104 connect with the chassis through a connecting rod 110. Frame 101 is hinged, and is arranged on both sides of the steering wheel 102 on the rear side of the vehicle body, and the driven wheel 103 is arranged on the side of the steering wheel 102 on the front side of the vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com