Underground driving ball screw oil pumping machine

A ball screw and pumping unit technology, which is applied in wellbore/well components, production fluids, earth-moving drilling and other directions, can solve problems such as hidden safety hazards, high manufacturing costs, low work efficiency, etc., to improve service life, Simple structure, no small rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

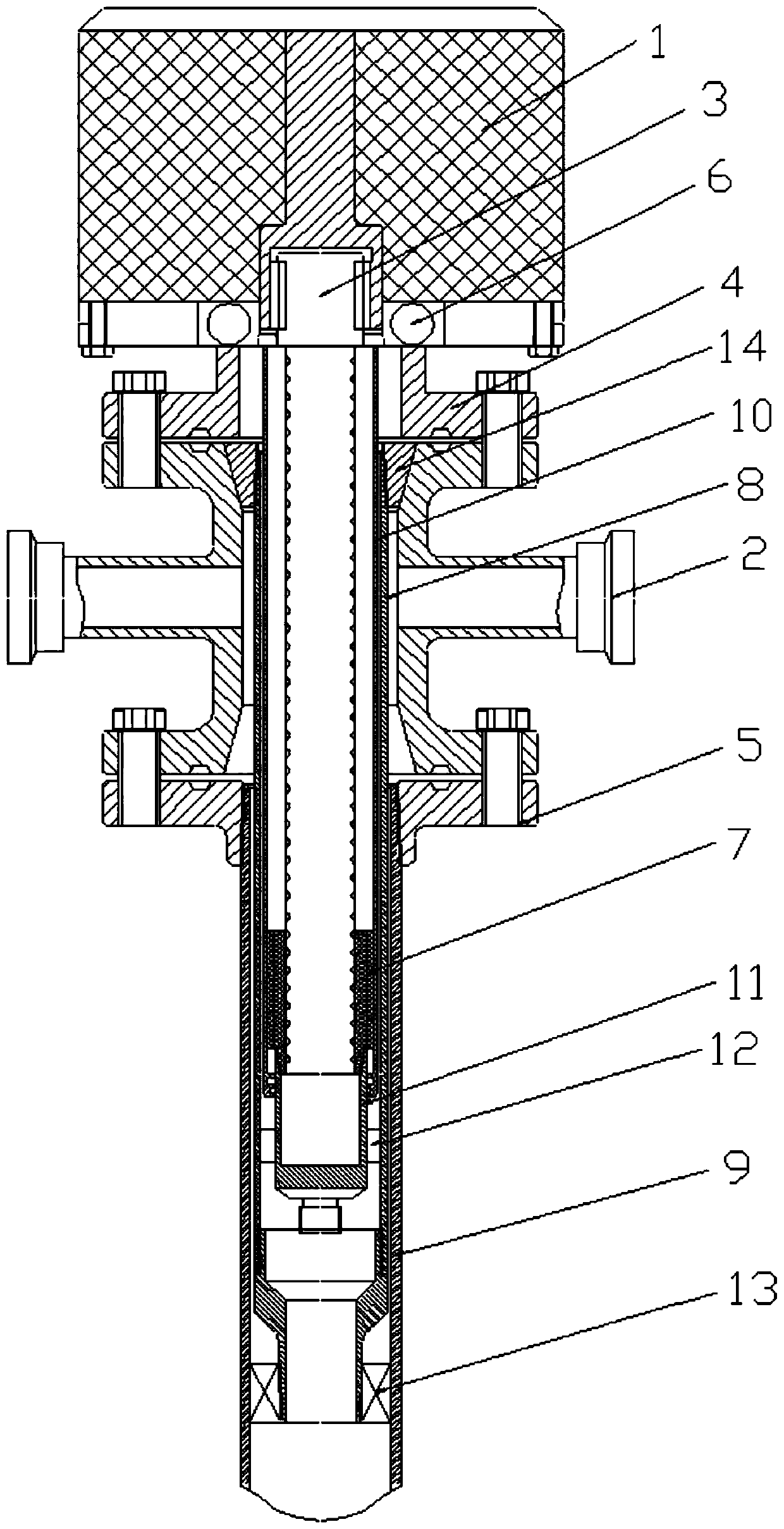

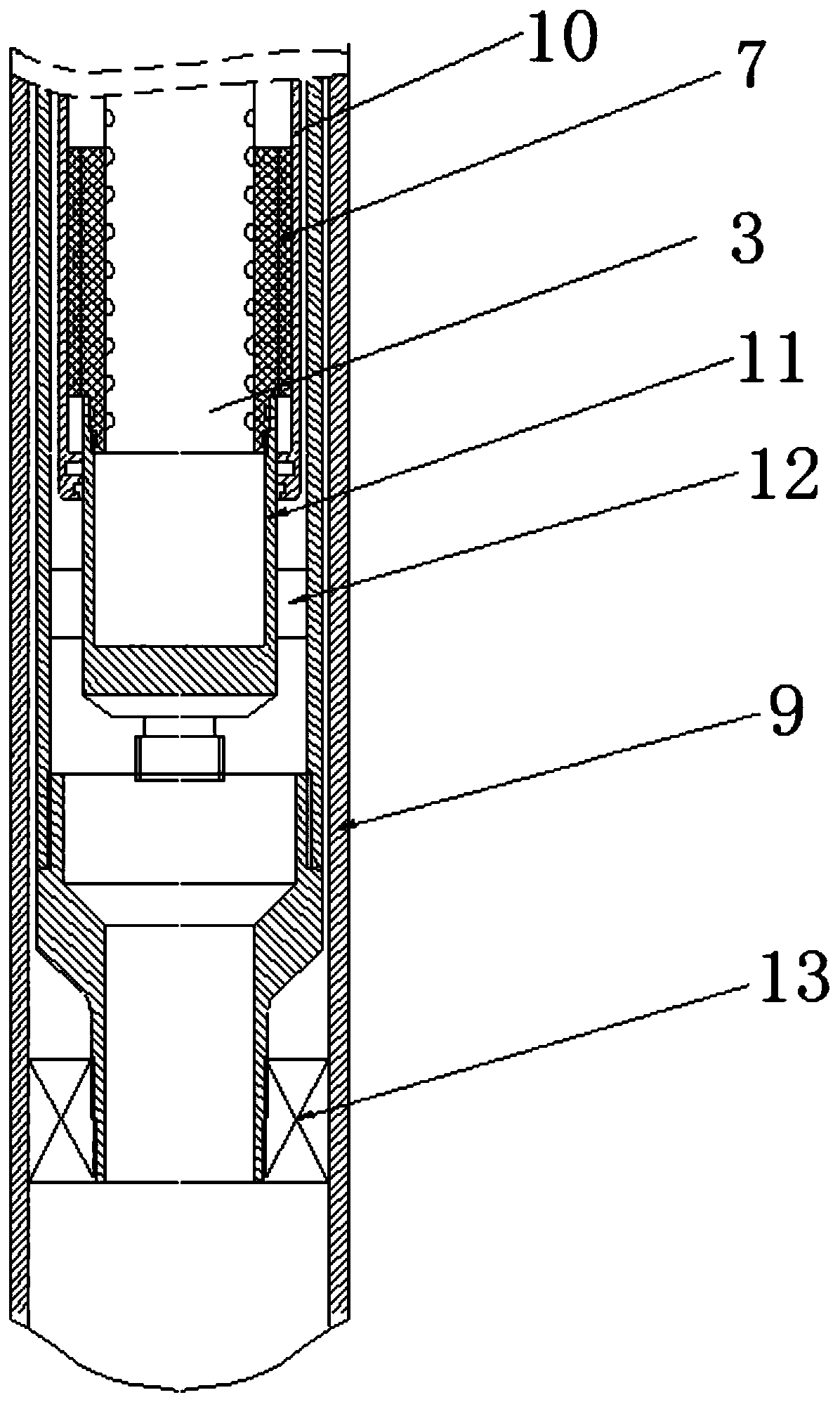

[0021] As shown in the figure, the downhole driven ball screw pumping unit includes the downhole driven ball screw pumping unit, including motor 1, wellhead cross 2, ball screw drive assembly and sucker rod,

[0022] The wellhead cross 2 is installed and fixed on the wellhead, the upper part of the wellhead cross 2 is fixedly connected with the upper flange 4 through bolts, and the lower part of the wellhead cross 2 is fixedly connected with the lower flange 5 through bolts; the ball wire The rod drive assembly includes ball screw 3, bearing 6, nut 7, oil pipe 8, bushing 9, upper seal sleeve 10, lower seal sleeve 11, anti-rotation guide key 12 and column anchor 13, the ball screw drive The assembly is installed underground and fixedly connected with the wellhead cross 2 through the upper flange 4 and the lower flange 5 respectively.

[0023] The wellhead cross 2 is installed and fixed at the wellhead, the upper part of the wellhead cross 2 is fixedly connected with the upper f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com