Integrated sealing type bearing device

A bearing device, sealed technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., to achieve the effect of reducing cost, reducing process difficulty and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

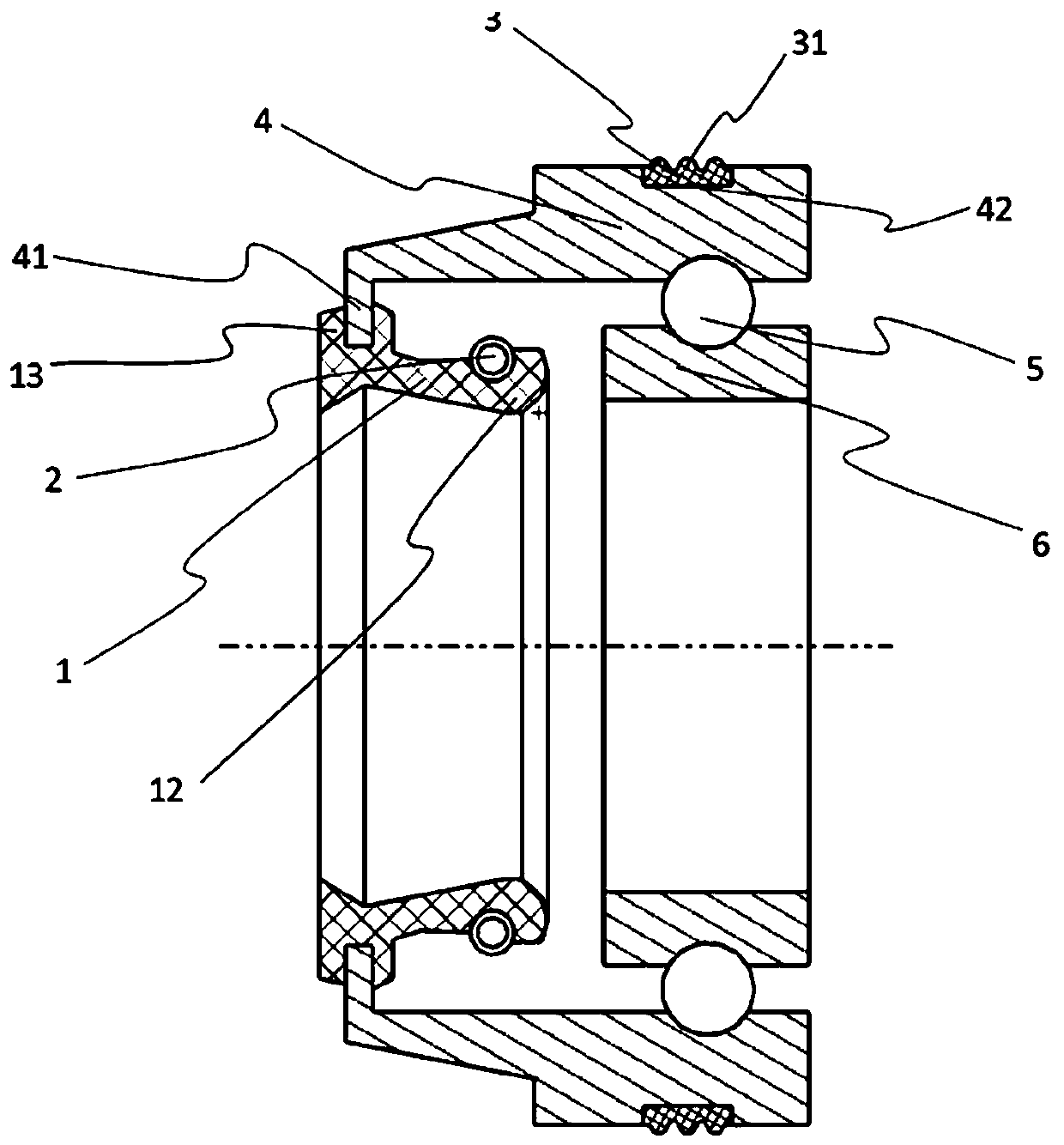

[0014] Integrated sealed bearing unit, including oil seal body and bearing. The bearing includes an outer ring 4 , rolling elements 5 and an inner ring 6 in sequence from outside to inside. The inner cavity of the inner ring 6 can pass through a shaft-type rotating member. The rolling element 5 is arranged between the outer ring 4 and the inner ring 6 to reduce the frictional force of the relative sliding of the outer ring 4 and the inner ring 6. The inner ring 6 is located inside the rolling element 5 to support the rotating shaft, and the outer ring 4 is located on the rolling element. The outside of body 5 plays a supporting and fixing role. The outer ring 4 axially extends parallel to the axial length of the inner ring, and a leg 41 protrudes from the extended end in the direction of the axis. The oil seal body 1 is located in the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com