Range hood

A technology for range hoods and fans, applied in the field of range hoods, can solve the problems of inconspicuous noise reduction, reduced flow loss, inability to effectively change the flow field outside the fan, etc., to achieve the effect of improving smoking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

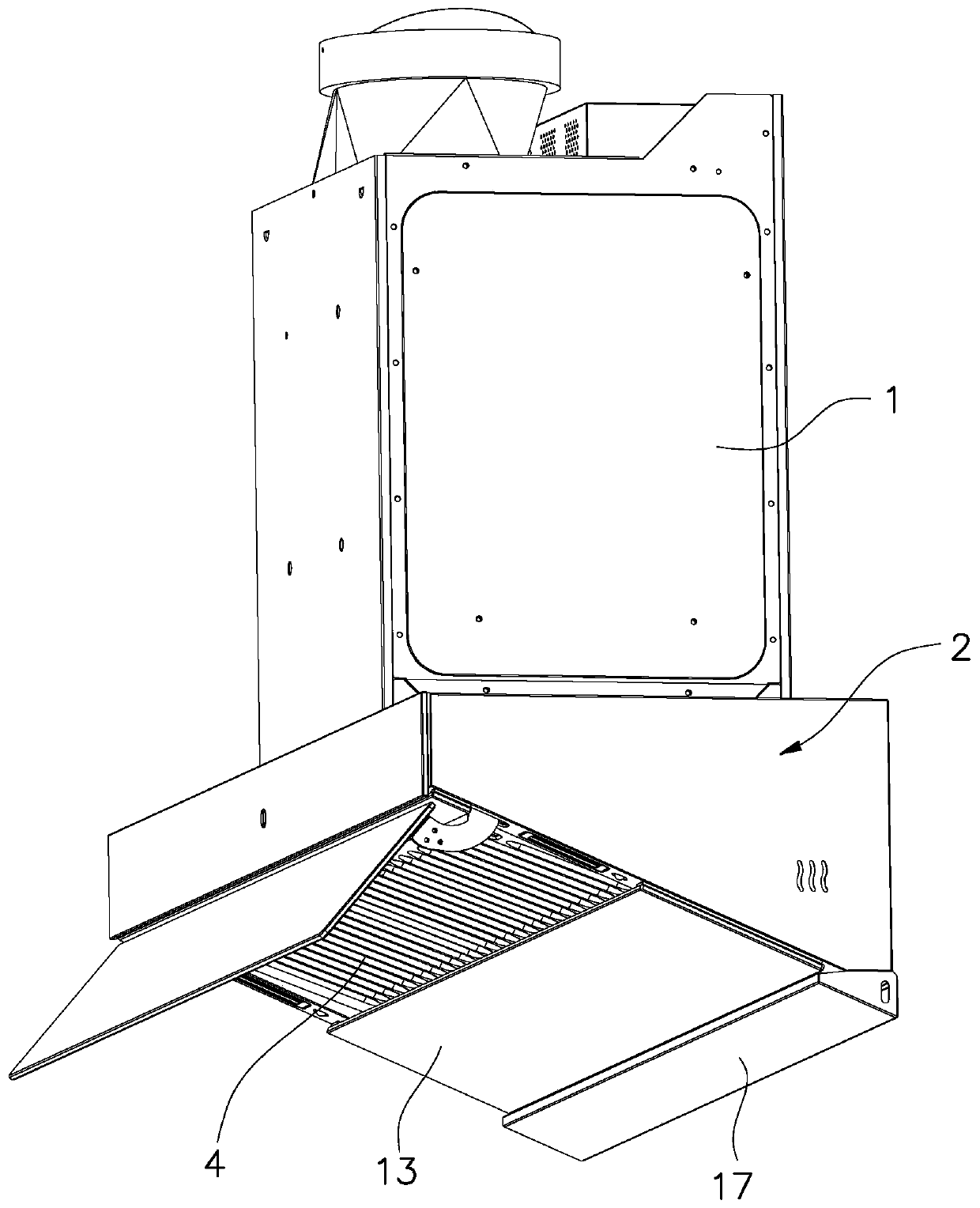

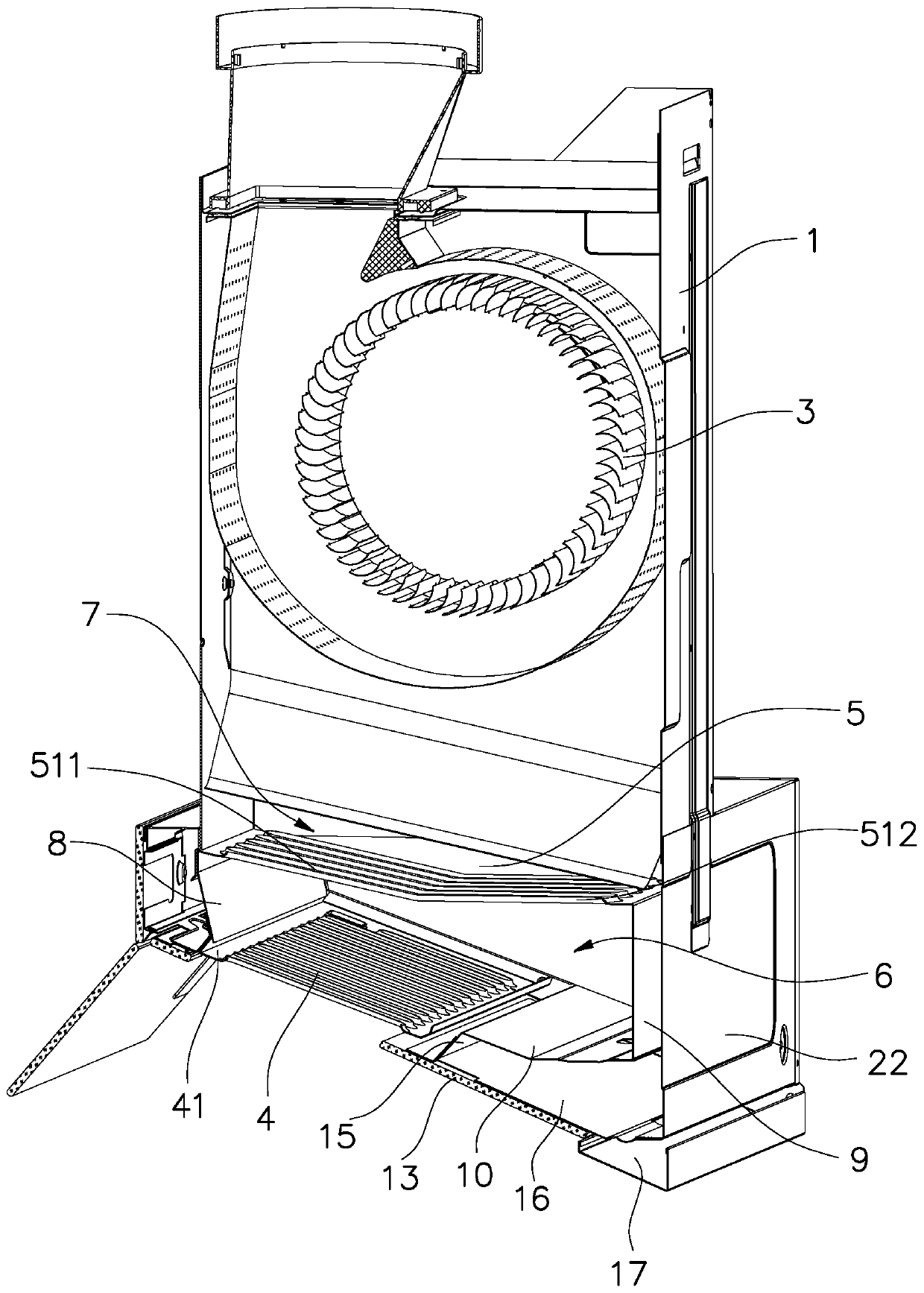

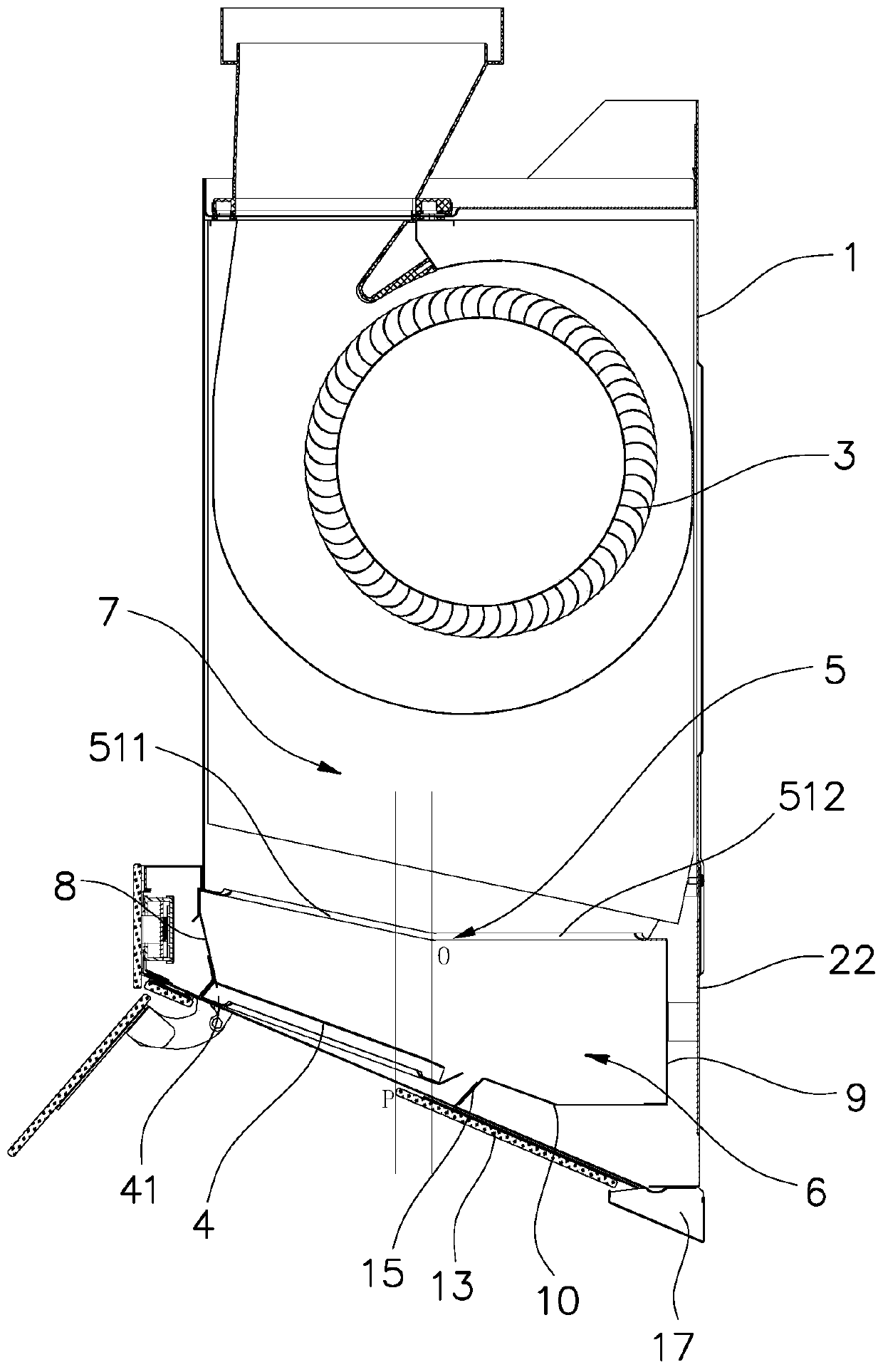

[0032] Such as Figure 1 to Figure 6 As shown, the range hood of this embodiment includes a fan frame 1 and a smoke collection hood 2 located below the fan frame. A fan 3 is installed inside the fan frame 1. The fan 3 is a centrifugal fan. A lower oil filter plate 4 is installed, and under the action of the blower fan 3, the oil smoke enters the inside of the range hood after being filtered by the lower oil filter plate 4. This is the prior art and will not be described here.

[0033] The range hood of this embodiment is equipped with an upper oil filter plate 5 inside the smoke collecting hood 2, and the upper oil filter plate 5 is located above the lower oil filter plate 4, and the upper oil filter plate 5 and the lower oil filter plate 4 form a The equalizing chamber 6 and the inner chamber of the fan frame 1 above the upper oil filter plate 5 form the main negative pressure chamber 7, and the volume V1 of the main negative pressure chamber 7 and the volume V2 of the equali...

Embodiment 2

[0043] Such as Figure 7 and Figure 8 As shown, the range hood of this embodiment cancels the rear panel, and the lower panel in Embodiment 1 is replaced by a noise-reducing partition 18, that is, the rear side of the upper oil filter plate 5 is connected to the rear side of the noise-reducing partition 18 On the back plate 22 of the smoke collecting hood, in this way, the inside of the pressure equalization chamber is divided into an upper pressure equalization chamber 19 and a noise reduction chamber 20 by a noise reduction partition 18, and a noise reduction hole 181 is opened on the noise reduction partition 18. Other structures of this embodiment are the same as those of Embodiment 1, and will not be further described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com