Rolling bearing fault diagnosis method under variable working conditions based on a vibration diagram and transfer learning

A rolling bearing and transfer learning technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve problems such as difficulty in extracting fault-sensitive features and changeable vibration signal distribution rules, and achieve effective diagnosis, The effect of reducing extraction difficulty and high diagnostic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

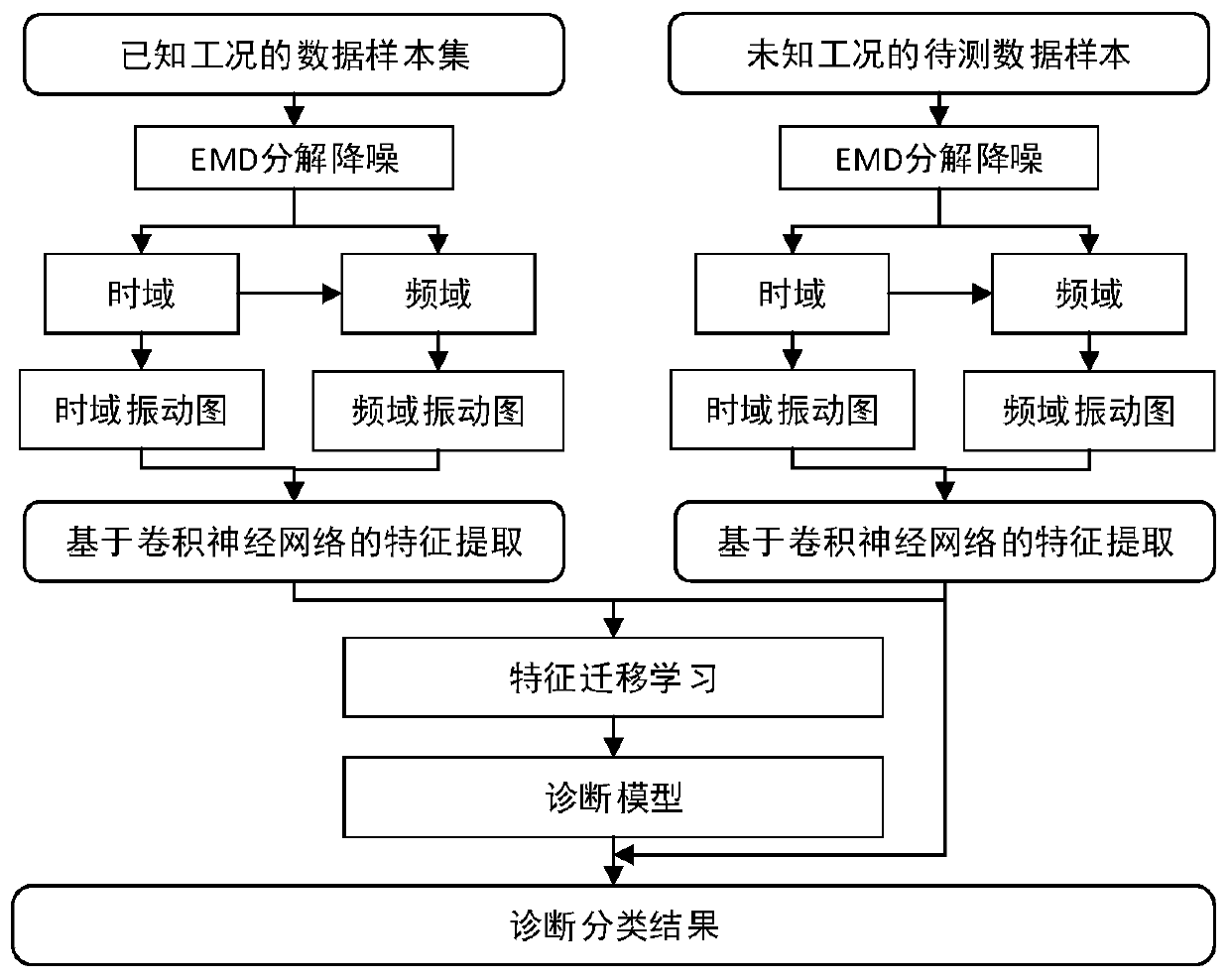

Method used

Image

Examples

Embodiment Construction

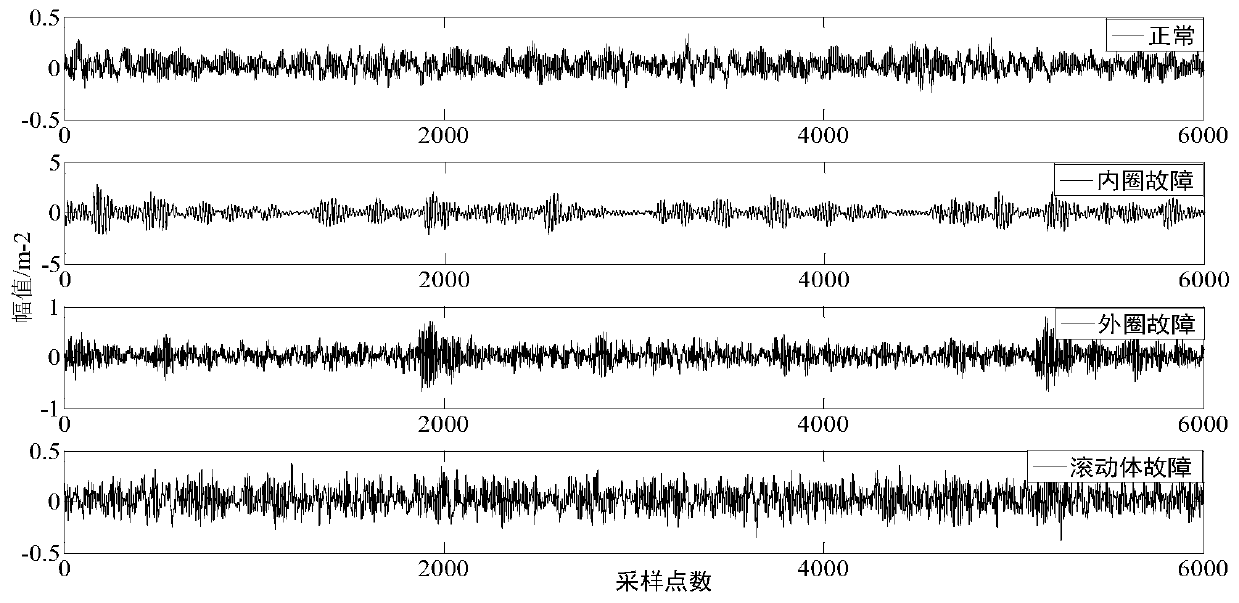

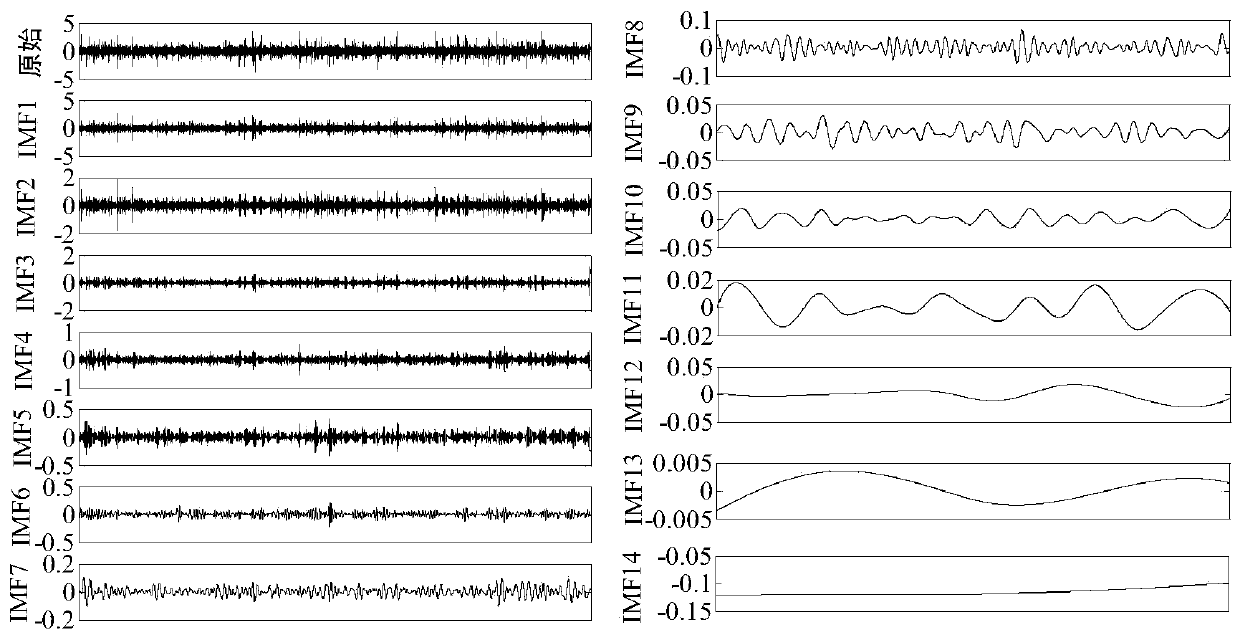

[0051]The concrete embodiment of the present invention selects the bearing fault experiment data disclosed by U.S. Case Western Reserve University to carry out the example test of the present invention, and this experiment selects SKF6205 bearing to test, and the number of balls in the bearing is 9, respectively in normal, outer ring fault, The inner ring fault and the rolling element fault are operated under 4 states, and each fault type has four loads. The detailed fault settings are shown in Table 1. The acceleration sensor is used for signal acquisition, and the sampling frequency is 12kHz. The data sample records all the data of the motor from 0 to 3 horsepower in detail.

[0052] Table 1 Data description of different fault types

[0053]

[0054]

[0055] Three groups of different types of experiments were carried out. The first group selected the diagnostic analysis of the same type of faults of the same size under different working conditions; the second group of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com