High-integrity container with anti-floating mechanisms for radioactive waste disposal

A radioactive waste and integrity technology, applied in portable protective containers, nuclear engineering, etc., can solve problems such as poor secondary grouting effect, unsealable workpieces, floating top of containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

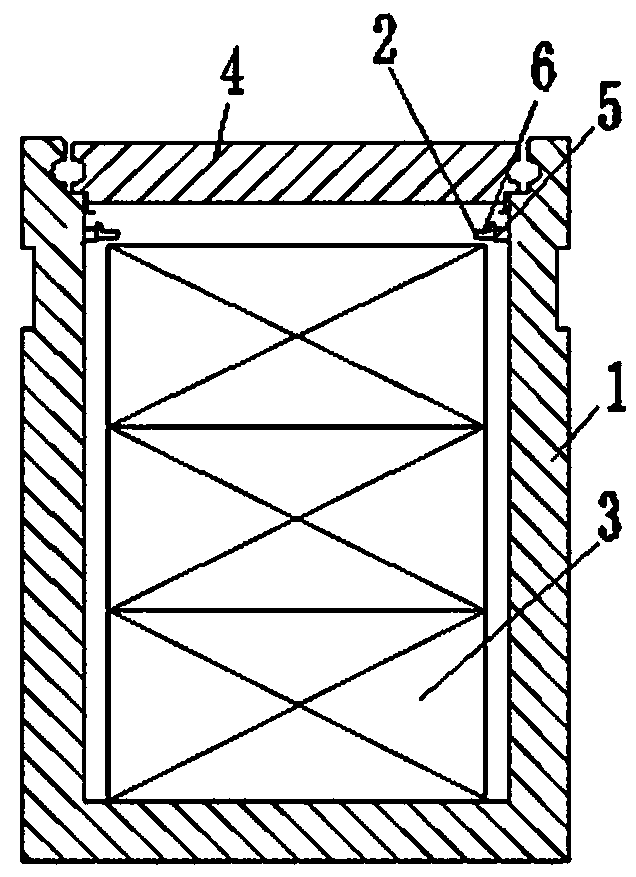

[0021] Example 1, such as figure 1 As shown, a high-integrity container for radioactive waste disposal containing an anti-floating mechanism mainly includes a container 1 with an open top, two anti-floating mechanisms 2 and three workpieces 3, the workpieces 3 are arranged in the container 1, and the anti-floating mechanism 2 Including the support 5 and the limit part 6, the anti-floating mechanism 2 is connected above the inner wall of the container 1 through the support 5, the limit part 6 can rotate along the support 5, when the workpiece 3 floats, the uppermost workpiece 3 top There is at least one contact surface or contact point with the anti-floating mechanism 2, and there is no contact surface or contact point between the top of the uppermost workpiece 3 and the support 5.

[0022] When the workpiece 3 is put into the container 1, the stop member 6 rotates downward along the support 5 or rotates left and right. Since the top of the workpiece 3 has no contact surface or...

Embodiment 2

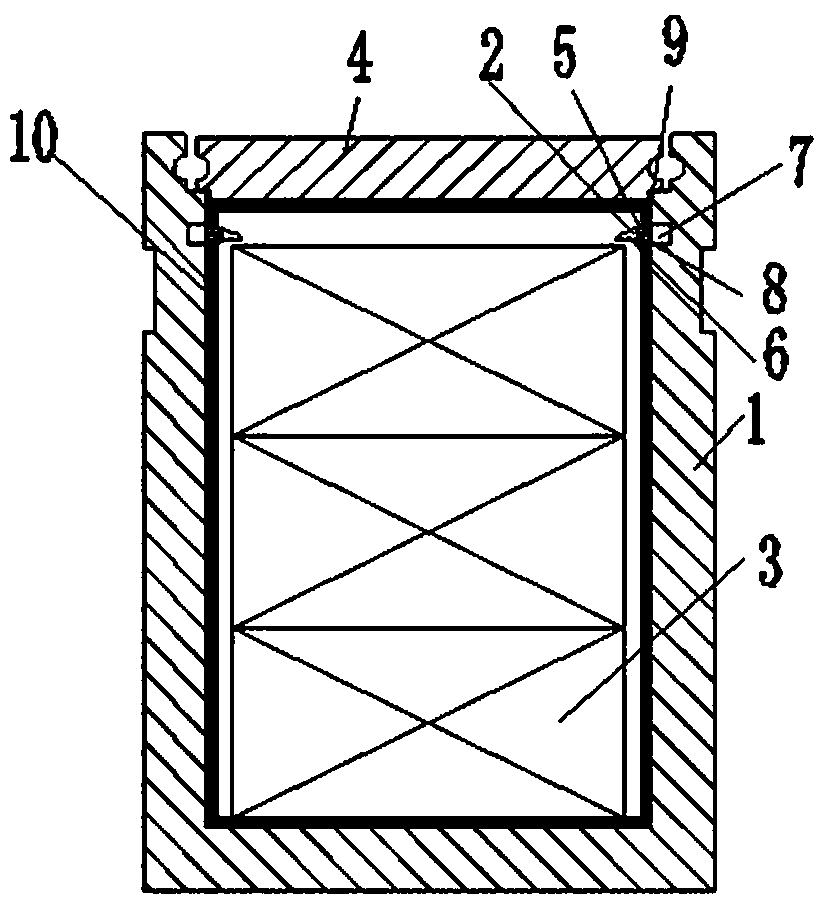

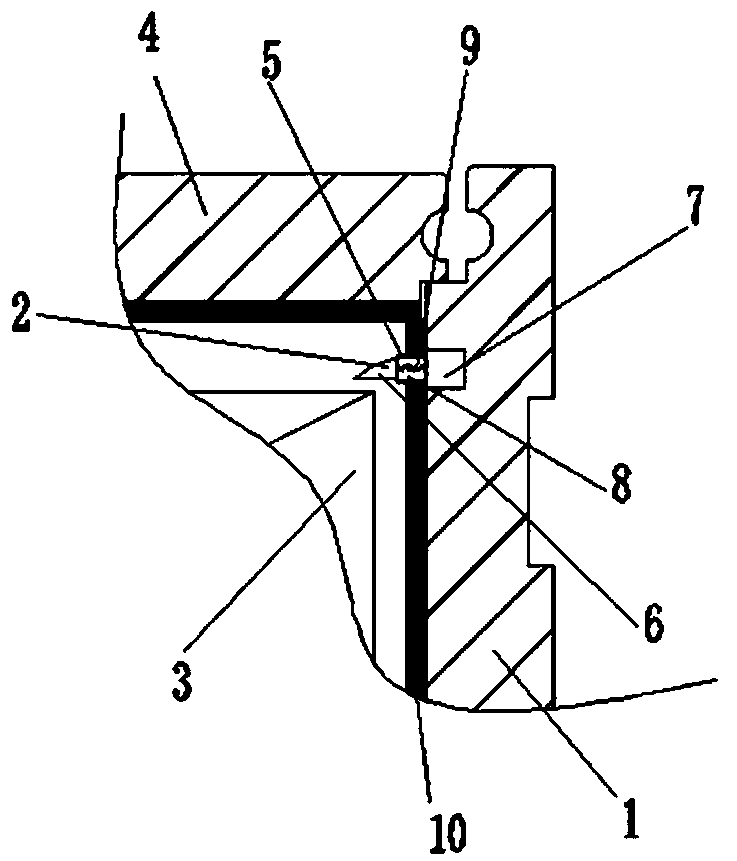

[0023] Example 2, such as figure 2 As shown, a high-integrity container for radioactive waste disposal containing an anti-floating mechanism mainly includes a container 1 with an open top, two anti-floating mechanisms 2, three workpieces 3 and a fixing device 7, and an anti-corrosion layer 10 is provided on the inner wall of the container. The workpiece 3 is arranged in the container 1, the fixing device 7 is pre-embedded in the inner wall 1 above the container 1, the material of the anti-floating mechanism 2 is a corrosion-resistant material, and the anti-floating mechanism 2 includes a support 5 and a limiting part 6, and the support 5 is connected to On the fixing device 7, through the connection of the fixing device 7, the anti-floating mechanism 2 and the container 1 are connected more firmly; the inside of the support 5 has an accommodation cavity 8 that can accommodate the limiting component 6, and the limiting component 6 passes through the elastic component 9 Connect...

Embodiment 3

[0025] Embodiment 3: Referring to Embodiment 2, the fixing device is connected to the upper inner wall of the container 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com