A kind of production method of tea packaging can

A production method and technology of packaging cans, which are applied in the field of tea packaging cans, can solve the problems of packaging cans that cannot be reused, unfavorable resource integration and utilization, and packaging cans waste, and achieve easy recycling, simple structure, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

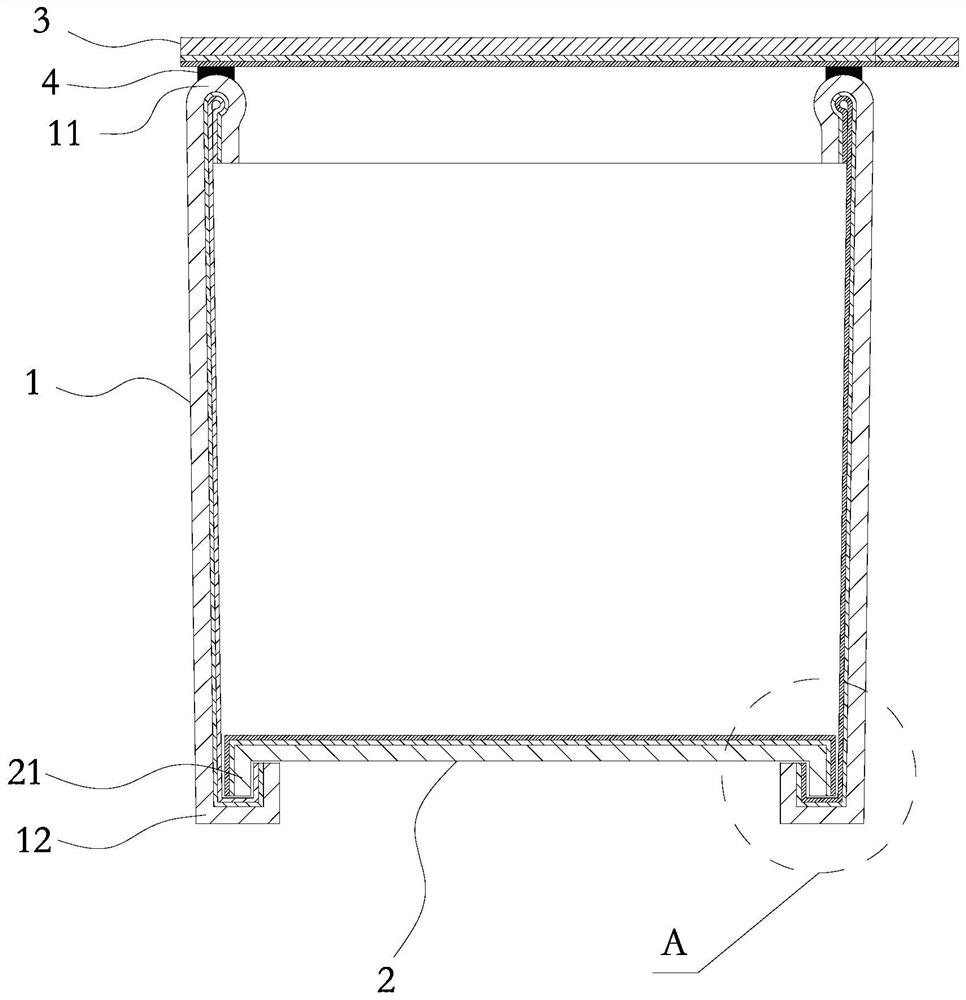

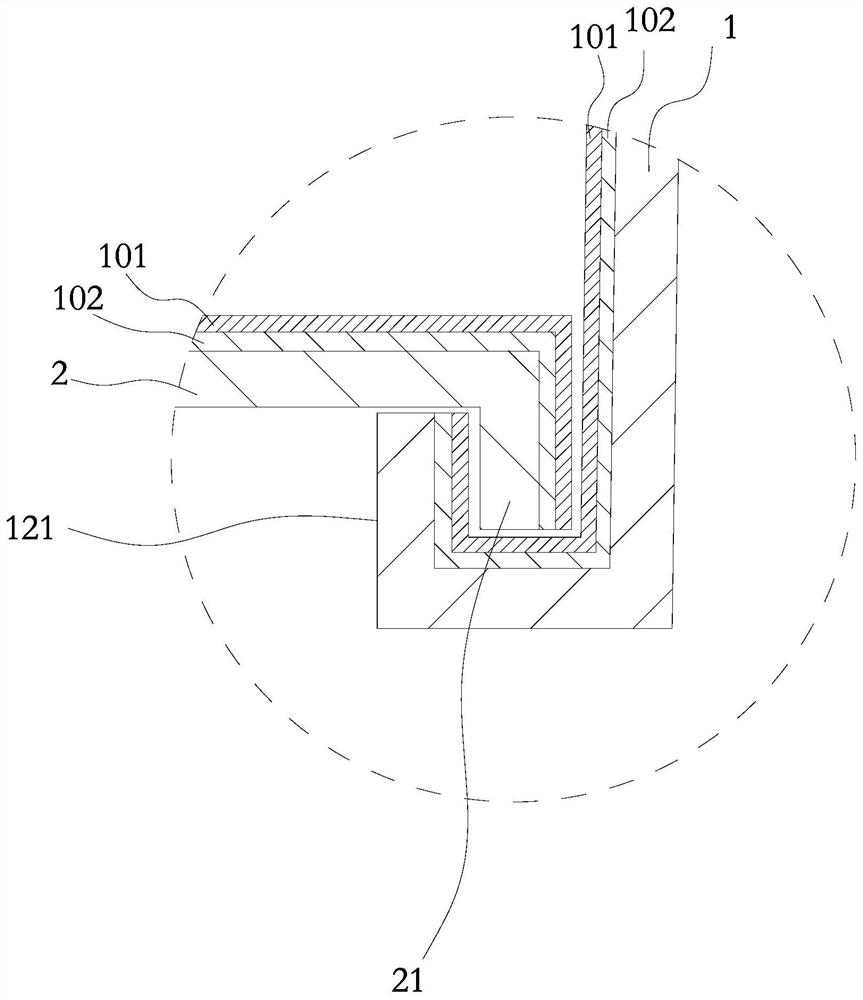

[0027] refer to figure 1 , figure 2 , the present embodiment provides a method for producing tea packaging cans, comprising the following steps:

[0028] 1. Raw material preparation: the preparation weight is 300g / cm 2 white cardboard, and carry out lamination treatment on its surface to form lamination layer 101;

[0029] 2. Prepare tank body 1: Wind the white cardboard processed in step 1 into a tank body 1 with a taper of 5° and a circular cross section, define the end of the tank body 1 with a larger opening as the upper end 11 of the tank body, The other end opposite to the upper end 11 of the tank body is the lower end 12 of the tank body;

[0030] 3. Prepare the bottom of the tank: use the same material as in step 1 to cut a film 2 whose diameter is 6mm larger than the inner diameter of the lower end 12 of the tank body, and fold down the part of the film whose radial outer side exceeds the inner diameter of the lower end 12 of the tank body to form a skirt Part 21...

Embodiment 2

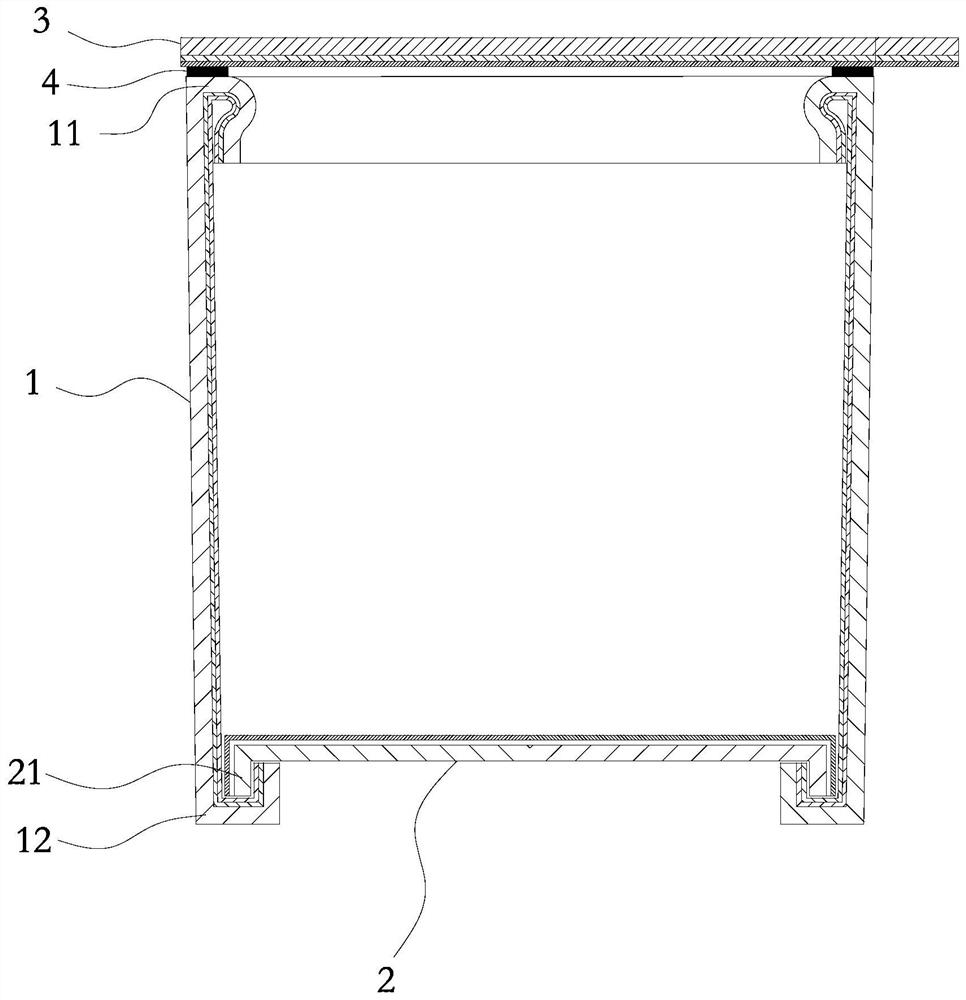

[0044] refer to image 3 , the present embodiment provides a method for producing tea packaging cans, comprising the following steps:

[0045] 1. Raw material preparation: the preparation weight is 300g / cm 2 white cardboard, and carry out coating treatment on its surface to form coating layer 101;

[0046] 2. Prepare tank body 1: Wind the white cardboard processed in step 1 into a tank body 1 with a taper of 5° and a circular cross section, define the end of the tank body 1 with a larger opening as the upper end 11 of the tank body, The other end opposite to the upper end 11 of the tank body is the lower end 12 of the tank body;

[0047] 3. Prepare the bottom of the tank: use the same material as in step 1 to cut a negative sheet 2 with a diameter 6mm larger than the inner diameter of the lower end 12 of the tank body, and fold down the part of the radially outer side of the negative sheet 2 that exceeds the inner diameter of the lower end 12 of the tank body to form skirt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com