Cleaning device used in laver processing course and its cleaning method

A technology for processing and cleaning equipment, applied in application, food processing, food science, etc., can solve problems such as difficulty in stirring, heavy metal poisoning, and human factors, and achieve simplified pumping procedures, less loss of business components, and heavy metals. The effect of content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

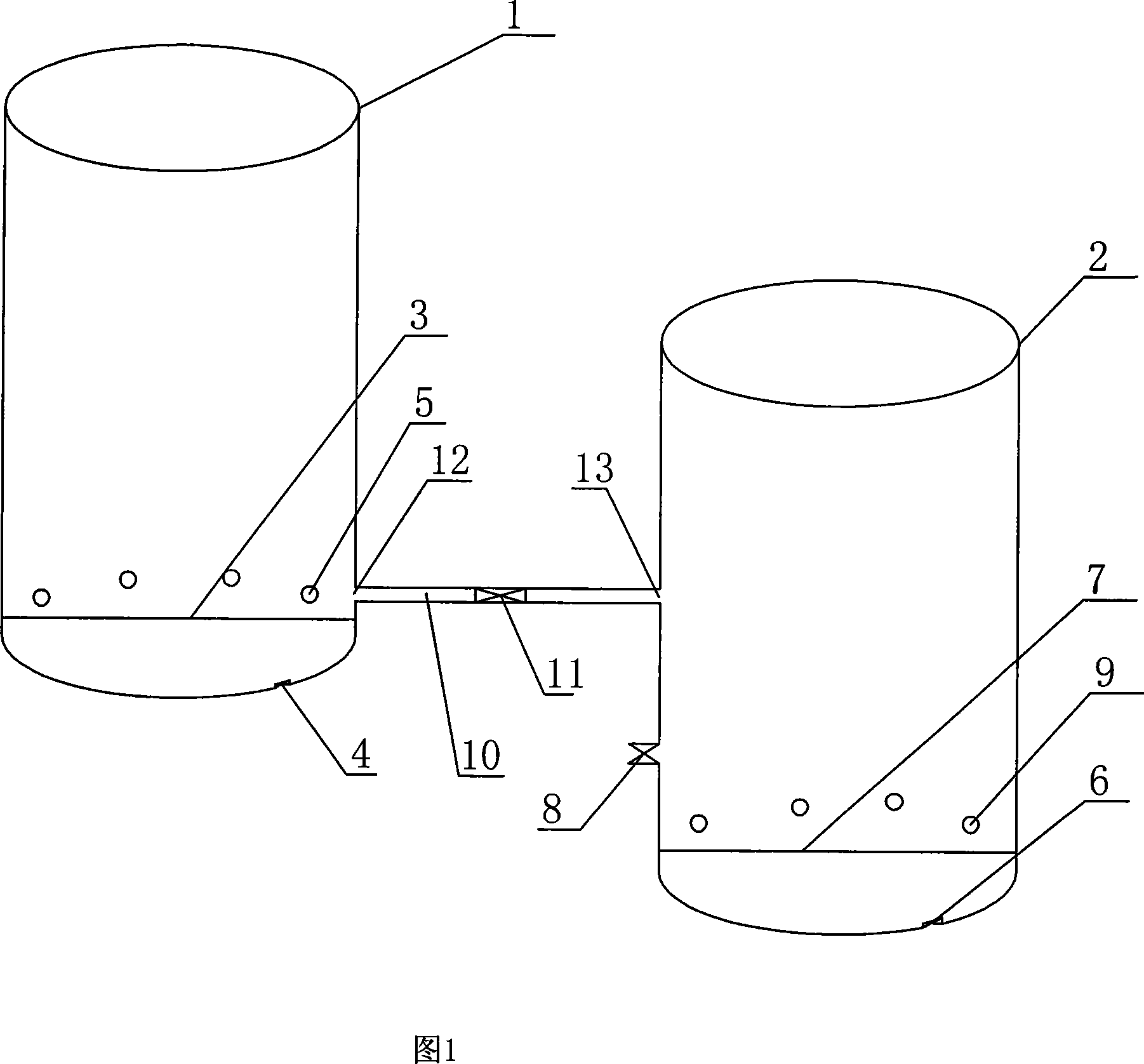

[0017] A kind of cleaning device in the seaweed processing process as shown in Figure 1, comprises that diameter is 2 meters, and height is the cleaning pool 1 of 6 meters and auxiliary cleaning pool 2, and the setting position of cleaning pool 1 is 2.2 meters higher than auxiliary cleaning pool 2 , a sewage outlet 4 is arranged at the bottom of the cleaning pool 1, a filter screen 3 is arranged at a distance of 60 cm from the bottom above the bottom of the cleaning pool 1, and a pool wall is surrounded between 70 cm to 1 meter above the bottom of the cleaning pool 1 8 micropore air inlets 5 are provided, and the micropore air inlet 5 is connected with an air pump (not shown in the figure), and an auxiliary sewage outlet 6 is arranged at the bottom of the auxiliary cleaning pool 2, and the distance above the bottom of the auxiliary cleaning pool 2 The bottom 60 centimeters place is provided with auxiliary filter net 7, is provided with dish discharge port 8 on the pool wall apa...

Embodiment 2

[0019] A kind of cleaning device in the laver processing process is basically the same as embodiment 1, the only difference is that a vegetable discharge port 8 is arranged at the end of the auxiliary cleaning pool 2 .

[0020] Water and impurity after washing will be removed by manpower or power if sewage outlet 4 or auxiliary sewage outlet 6 are not established.

[0021] Filter screen 3 or auxiliary filter screen 7 are located at near the bottom of the pond and are near better, because the impurity of laver is generally not a lot.

[0022] The quantity of micropore air inlet 5 and auxiliary micropore air inlet 9 is established according to the size of the pond, and it is better to be located at the lower position of the pond, so that the bubbling effect is better.

Embodiment 3

[0024] A cleaning method during laver processing, comprising the following steps: (1), closing the sewage outlet 4 and the valve 11, pumping 5 tons of clean seawater into the cleaning pool 1 with a water pump, and then adding the harvested surface water to drain the surface water 300 kilograms of fresh laver; (2), start the air pump of 300 W, just send air into seawater from microporous air inlet 5, make seawater bubble, thereby laver fluctuates in seawater, and bubbling 16 minutes, in laver Most of the impurities are blown down, and the impurities sink to the bottom of the pool through the filter screen 3, then turn off the air pump and let it stand for 5 minutes to silence the impurities; (3), close the auxiliary sewage outlet 6 and the vegetable discharge outlet 8, and open the water flow pipe 10 valve 11, the laver and part of the seawater in the cleaning tank 1 flow into the auxiliary cleaning tank 2, after all the laver flows in, close the valve 11 of the water flow pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com