Pressing magnetic attraction device of transformer sheet inserting machine

A technology of a magnetic suction device and a chip inserter, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described in conjunction with the following examples.

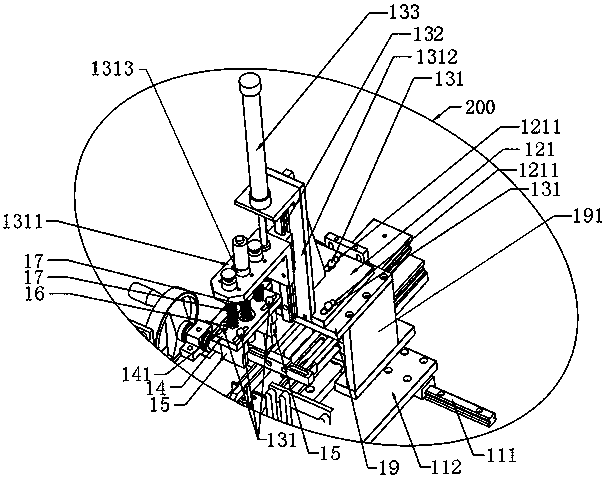

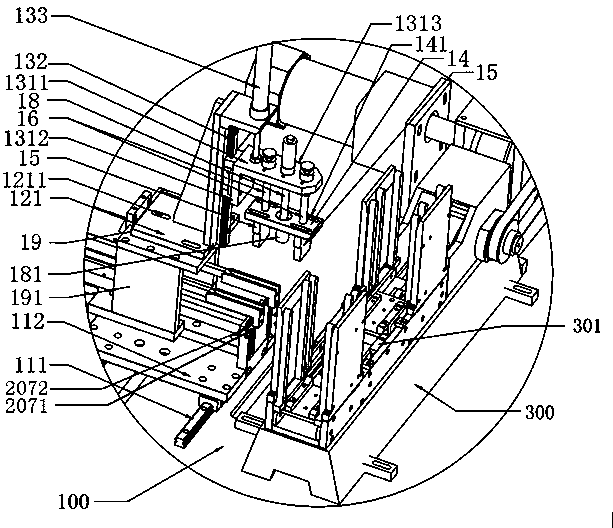

[0029] The horizontal and vertical directions of the present invention are based on the surface of the frame 100 as the horizontal plane, moving left and right and moving forward and backward on the horizontal plane, and the vertical direction of the present invention refers to the direction perpendicular to the horizontal plane.

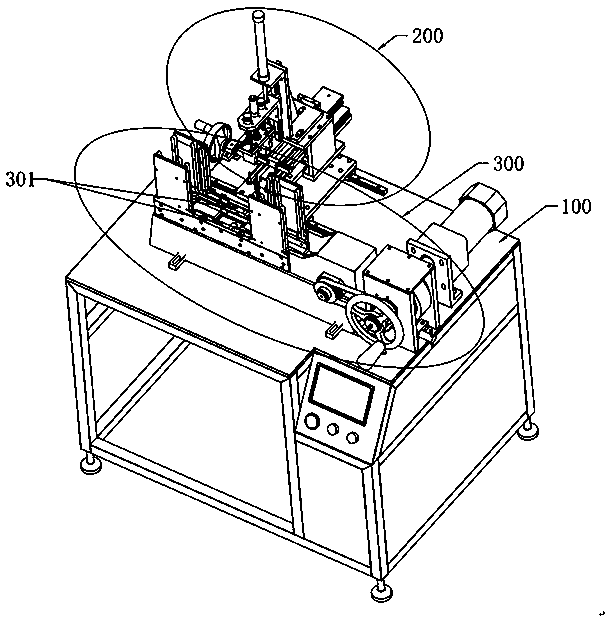

[0030] A compression magnetic device of a transformer inserting machine in this embodiment, such as Figure 1 to Figure 4Shown includes a frame, an E sheet pressing device and an I sheet magnetic suction device arranged on the frame 100, and the compression magnetic suction device of a transformer inserting machine includes an adjustment mechanism, a lifting device and a compression head, The adjustment mechanism includes a horizontal adjustment mechanism capable of driving the lifting device to move laterally and a longitudinal adjustment mechanism capab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com