Food processing equipment

A food processing and equipment technology, which is applied in the field of food processing equipment with a safety cover opening device, can solve the problem that electronic components are easily interfered by environmental factors, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

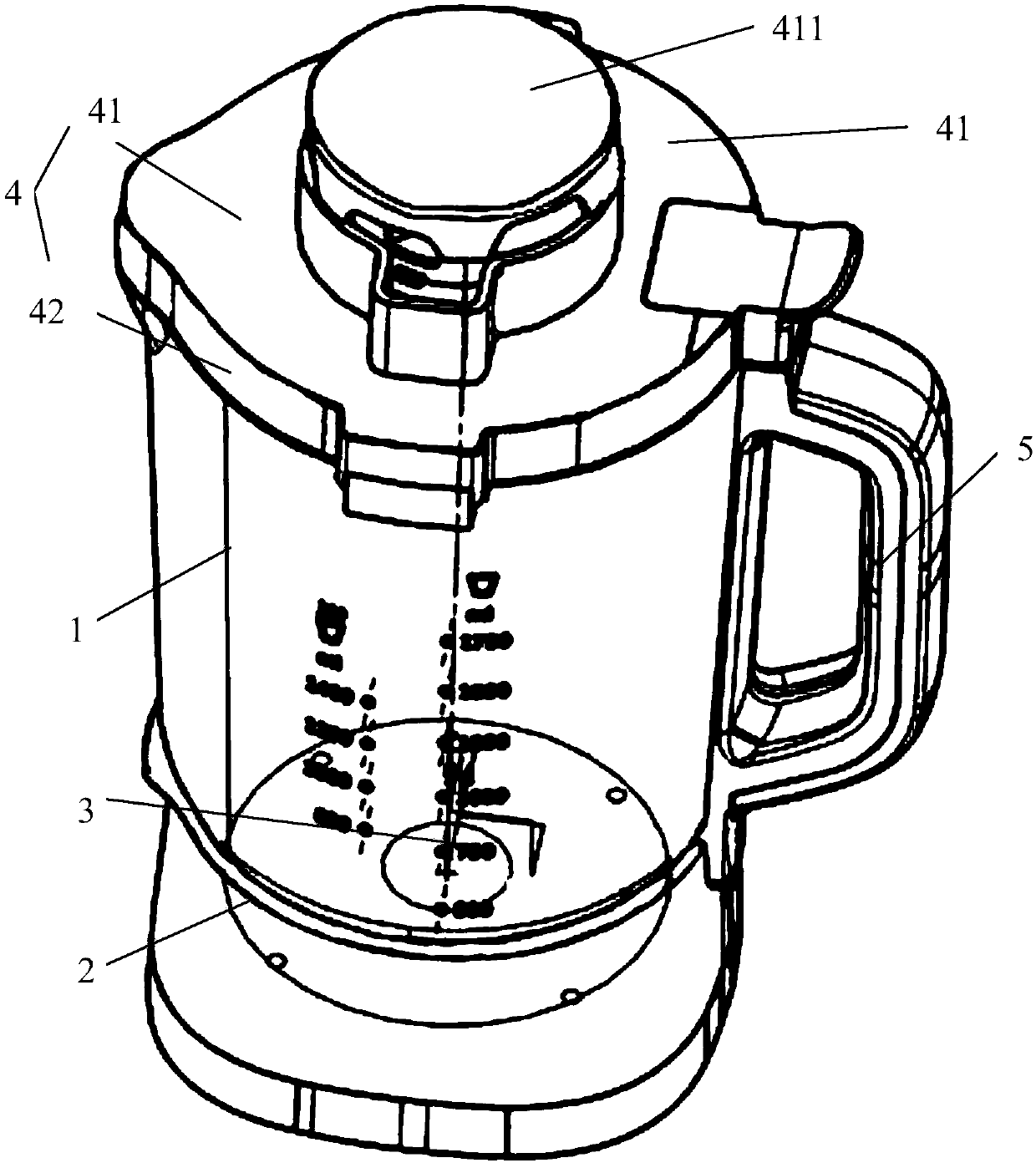

[0035] Figure 1 to Figure 7The first embodiment of the food processing equipment of the present invention is shown, which includes a processing container 1, a driving device 2 and a processing assembly 3 driven by the driving device 2 are arranged inside the processing container 1, and a container cover is arranged on the outside of the processing container 1 4 and the handle 5, the container cover 4 is provided with an interlock mechanism 6, the handle 5 is provided with a safety control assembly 7, the interlock mechanism 6 fixes the container cover 4 on the opening of the processing container 1, and the safety control assembly 7 controls the driving device 2, the interlock mechanism 6 is magnetically connected with the safety control assembly 7. The processing container 1 is a cylindrical or other regular-shaped open device for placing food materials to be processed. The driving device 2 provides power for the processing component 3, usually a motor. The processing assemb...

Embodiment 2

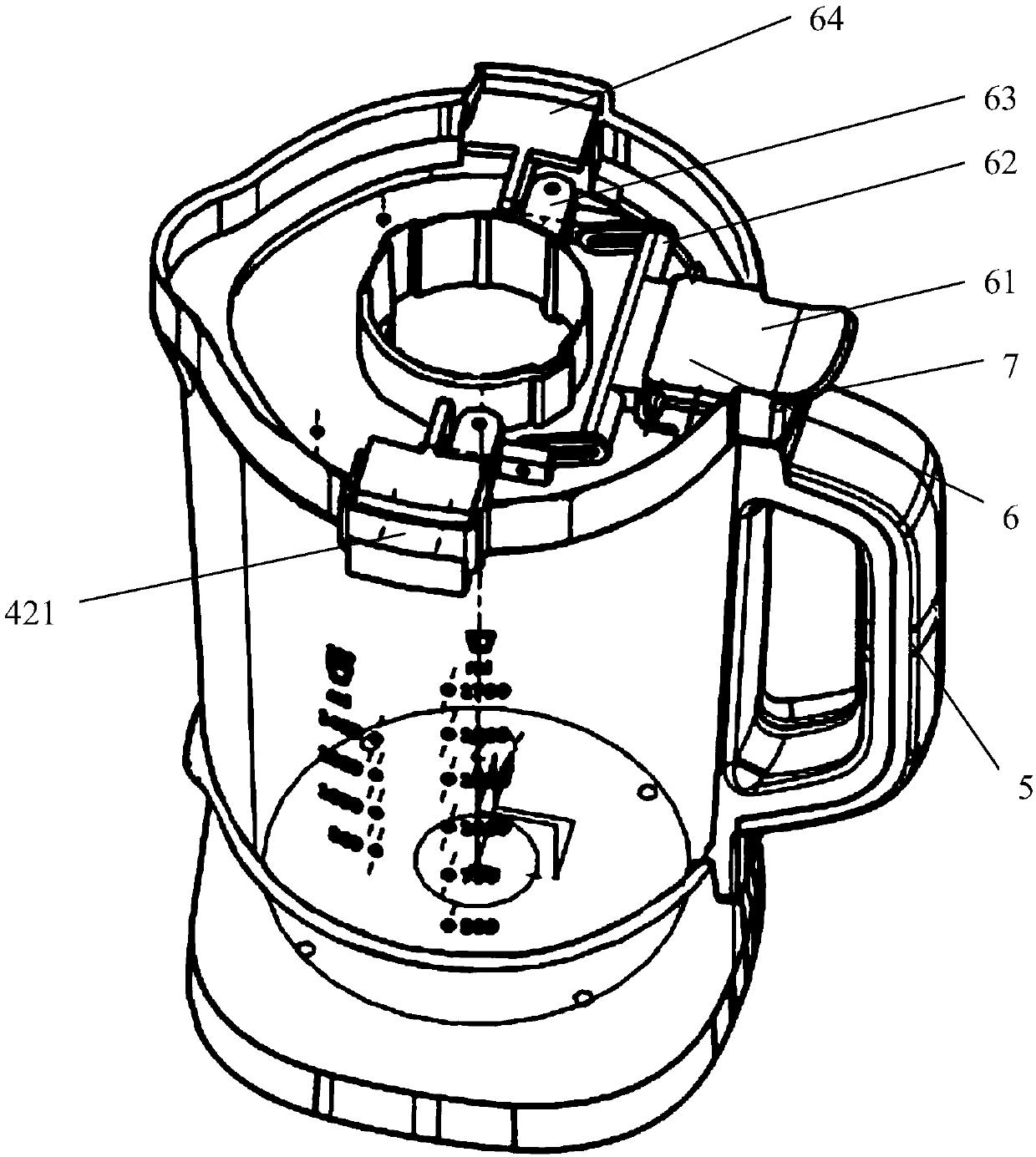

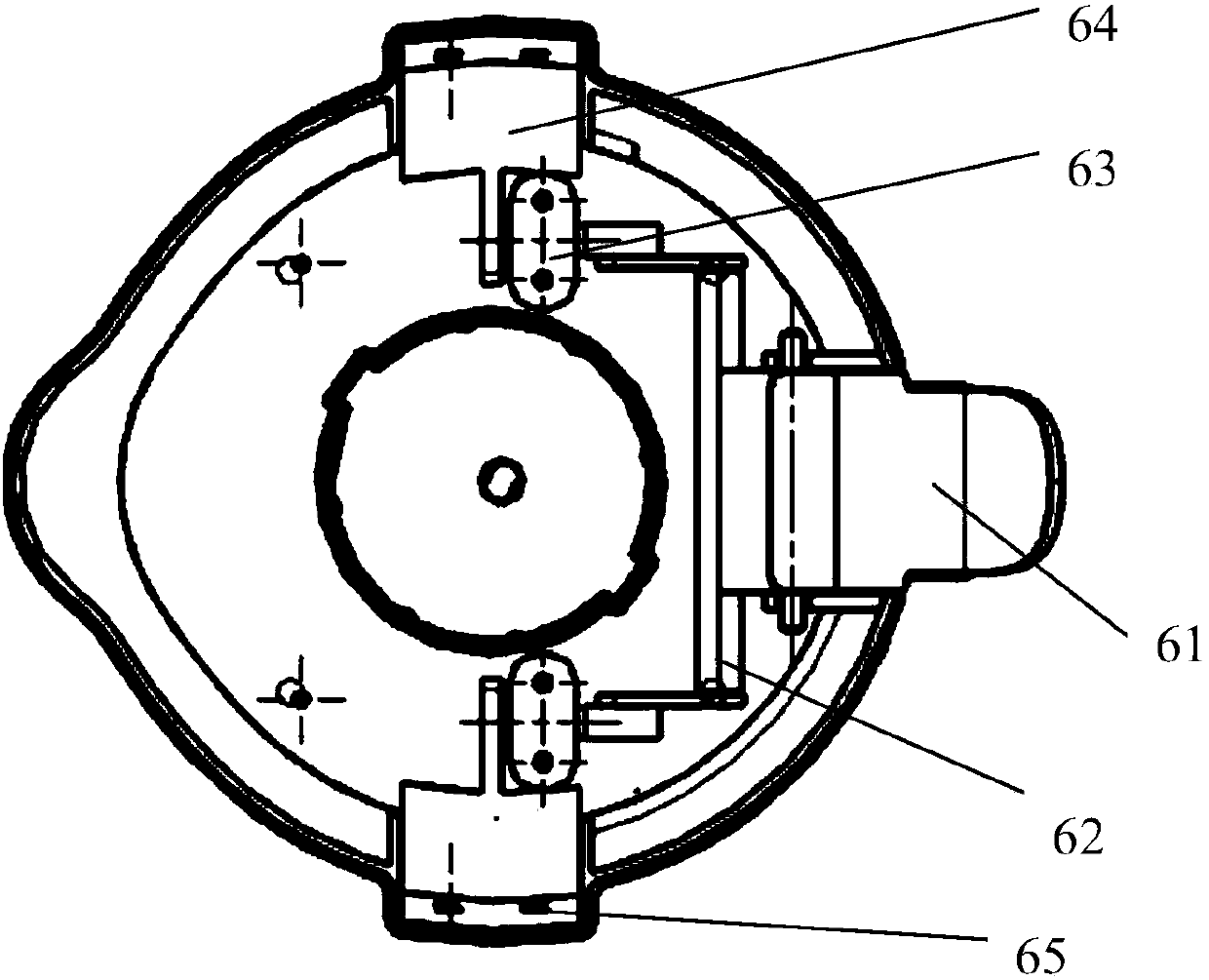

[0039] Figure 8 The second embodiment of the food processing equipment of the present invention is shown. The difference from the first embodiment is that the container cover 4 in this embodiment includes an upper cover 41 and a lower cover 42 that are detachably connected to each other, and the lower cover The left and right ends of 42 are respectively provided with protruding locks 421, which are fastened with the lugs 11 on the processing container 1; the container cover 4 is screw connected with the processing container 1; the interlocking mechanism 6 includes a rotary knob 66, and the rotary knob 66 It is rotatably connected with the lower cover 42; the safety control assembly 7 includes a plurality of reed switches 71, magnets 72 and a coupler 73 located at the bottom of the processing container 1, the coupler 73 is electrically connected with the driving device 2, and the reed switch 71 is arranged on the handle 5 In the contact part with the processing container 1, th...

Embodiment 3

[0041] The third embodiment of the food processing equipment of the present invention includes a processing container 1, a driving device 2 and a processing assembly 3 driven by the driving device 2 are arranged in the processing container 1, and a container cover 4 arranged on the outside of the processing container 1, the container The cover 4 is provided with an interlock mechanism 6 and a safety control assembly 7, the interlock mechanism 6 fixes the container cover 4 on the opening of the processing container 1, and the safety control assembly 7 controls the operation and stop of the driving device 2. The difference from the first embodiment is that there is no handle 5 on the processing container 1 of this embodiment, the safety control assembly 7 is transferred to the container cover 4 by the handle 5, and the reed switch 71 of the safety control assembly 7 is arranged on the upper cover 41, the magnet 72 is located on the lower cover 42; the reed switch 71 is electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com