Bad rice grain color selecting device and color selecting method in polished rice production process

A technology of production process and color sorting device, applied in sorting and other directions, can solve problems such as unfavorable production, enlarged device volume, low efficiency of color sorting device, etc., and achieve the effect of reducing the possibility of clogging and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

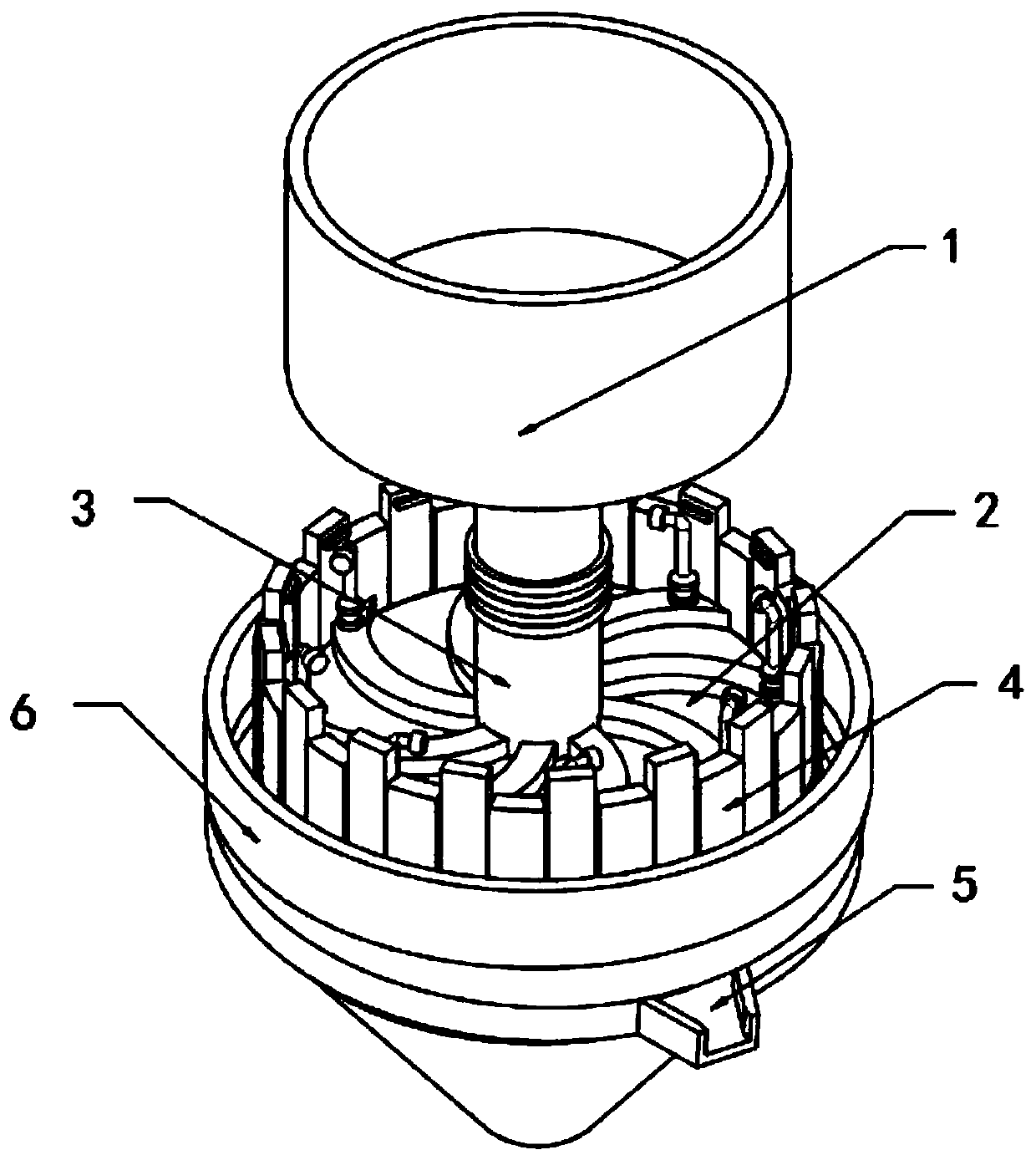

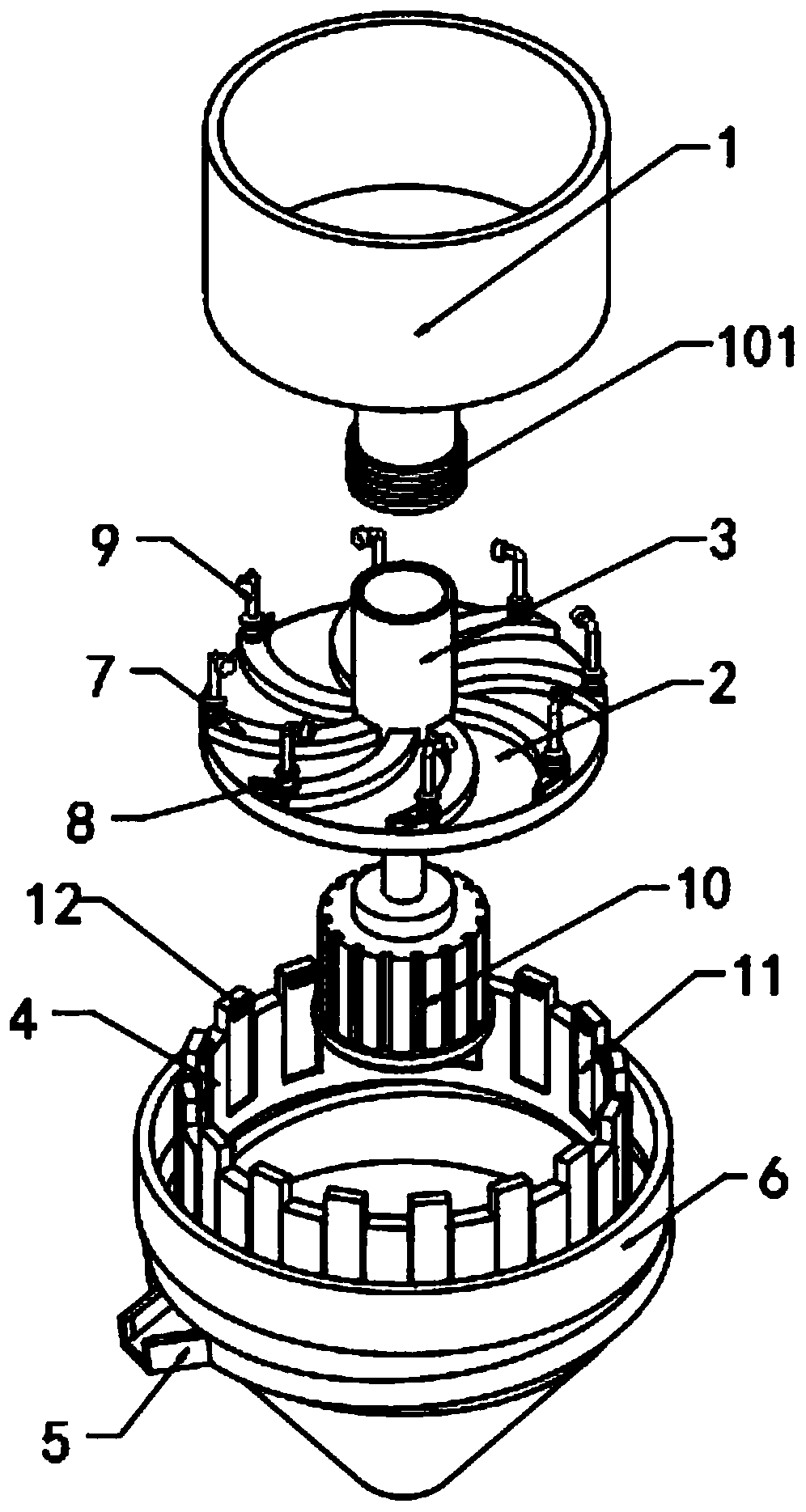

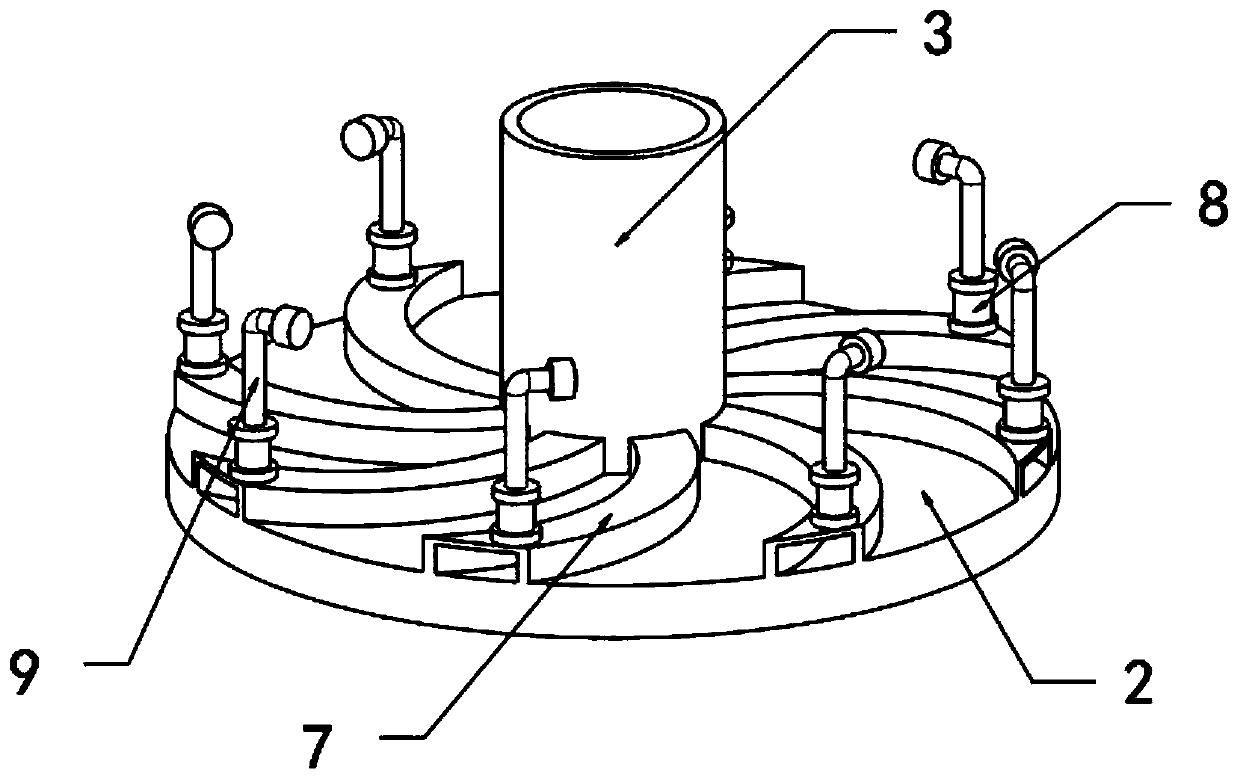

[0040] Example 1, please refer to Figure 1-6 , the present invention provides a technical solution: bad rice grain color sorting device and color sorting method in the polished rice production process, including a feeding tube 1, a distribution tray 2 and a receiving tube 4, and the inner center of the receiving tube 4 is concentrically arranged with a sub-section Material tray 2, and the top of the distribution tray 2 is provided with a feeding tube 1, the center of the feeding tray 2 is welded with a connecting pipe 3, and the connecting pipe 3 is connected to the feeding tube 1 in rotation, and the feeding tube 1 Bearing sleeve 101 is set on the outer side of the bottom of the bottom, and the feeding tube 1 is rotationally connected with the connecting pipe 3 through the bearing sleeve 101. During the rotation of the powder tray 2 at the bottom, due to the setting of the bearing sleeve 101, the feeding Cylinder 1 will not rotate together with the distribution tray 2. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com