Workholding device for forging

A technology for workpiece clamping and forging, which is applied in the field of forging workpiece clamping devices, which can solve problems such as high cost, damage to forging machines, and easy damage, and achieve the effects of reasonable structure setting, fast clamping operation, and stable stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

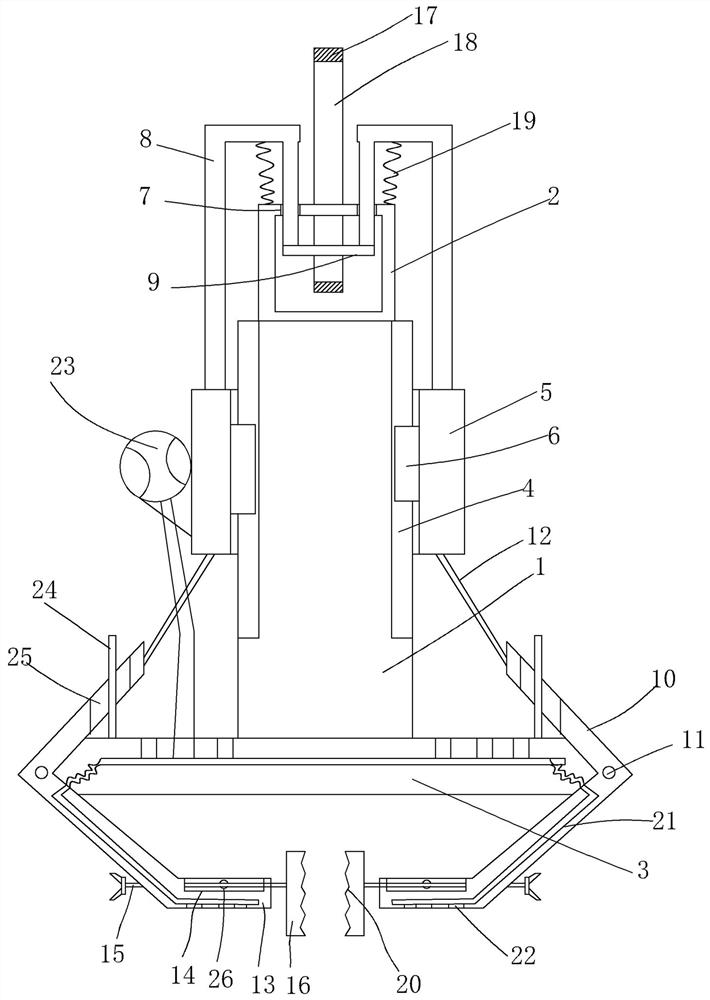

[0016] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0017] See figure 1 , a workpiece clamping device for forging, comprising a suspension rod 1, a suspension ring 2 fixed on the top end of the suspension rod and a clamping seat 3 fixed on the bottom end of the suspension rod, uniformly provided on the outer wall of the suspension rod The guide vertical groove 4 is provided with a collar 5 on the outside of the boom, and a guide slider 6 is integrally formed on the inner wall of the collar, and the guide slider is arranged in the guide vertical groove. The top wall of the suspension ring is provided with two circular holes 7, and an n-shaped support 8 is symmetrically fixed on the top of the collar, and the inner vertical rod of the n-shaped support extends into the suspension ring from the circular hole, and is arranged in the suspension ring. There is a transverse bearing bar 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com