A welding device and welding method for capstan and support shaft of pepper removal machine

A technology for welding devices and supporting shafts, which is applied in welding equipment, auxiliary devices, tin feeding devices, etc., and can solve problems such as increased radial load of bearings, damage to the cutter and roller, and overload of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

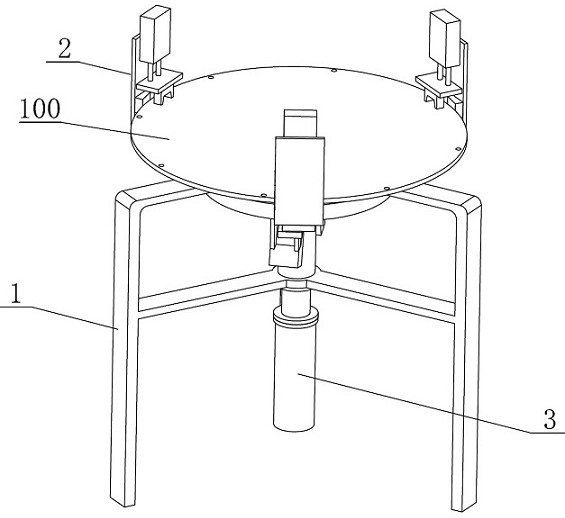

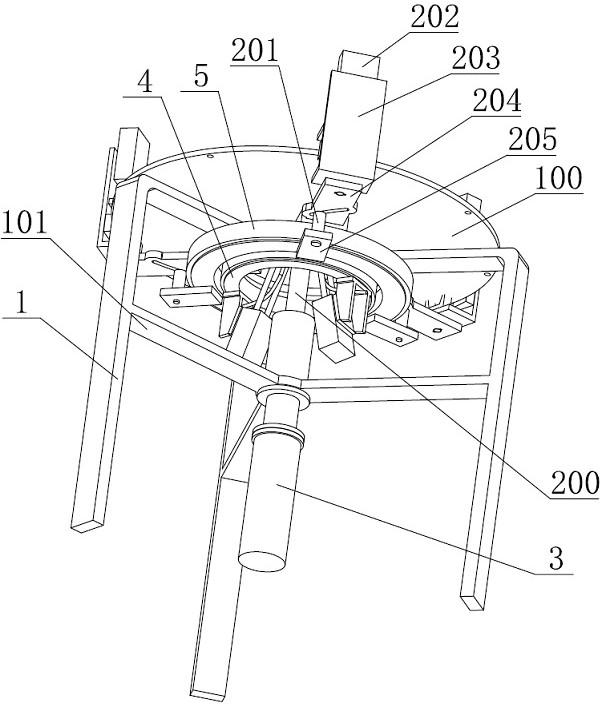

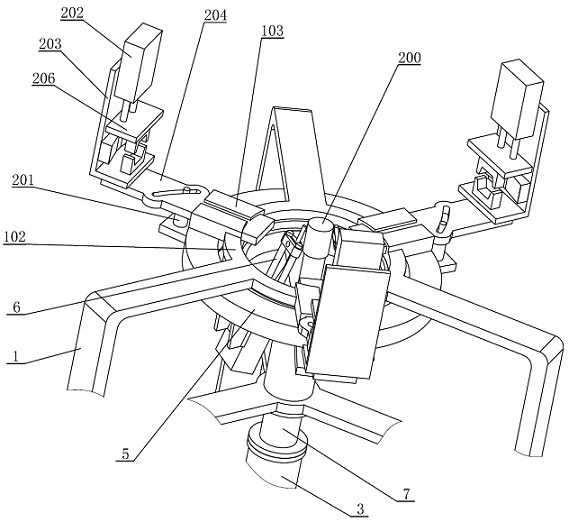

[0049] combine Figure 1-10 , a kind of capsicum of the present invention removes the welding device of machine end cover and support shaft, comprises support frame 1, end cover clamping mechanism 2, support shaft cylinder 3, inner turntable 4, outer turntable 5, welding mechanism 6, connecting sleeve 7. The guide support sleeve 8 is defined as the inner side toward the center of the end cover 100 and the outer side if it is opposite, so as to describe the present application. The end cover clamping mechanism 2 includes a guide pin 201, a compression cylinder 202, a compression frame 203, a sliding plate 204, a fixed support plate 205, an upper compression plate 206, a lower compression block 207, and an upper compression block 208. , side V-shaped block 209, limit key 210, hinge shaft 211, the welding mechanism 6 includes a welding support seat 601, a welding cylinder 602, a welding torch 603, and a welding torch fixing block 604.

[0050] The upper end of the support frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com