High lift-drag ratio laminar flow aerofoil profile suitable for low altitude and low speed unmanned aerial vehicle

A high-lift-to-drag ratio, unmanned aerial vehicle technology, applied in the direction of the wing shape, can solve the problems of stall characteristics and poor lift-drag characteristics, increase the empty weight of the wing and the whole machine, and less laminar airfoil design, so as to achieve stall Smooth characteristics, excellent torque characteristics, and improved stall characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, wherein the embodiments include theoretical calculation analysis and actual flight tests. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention, and the detailed description is as follows.

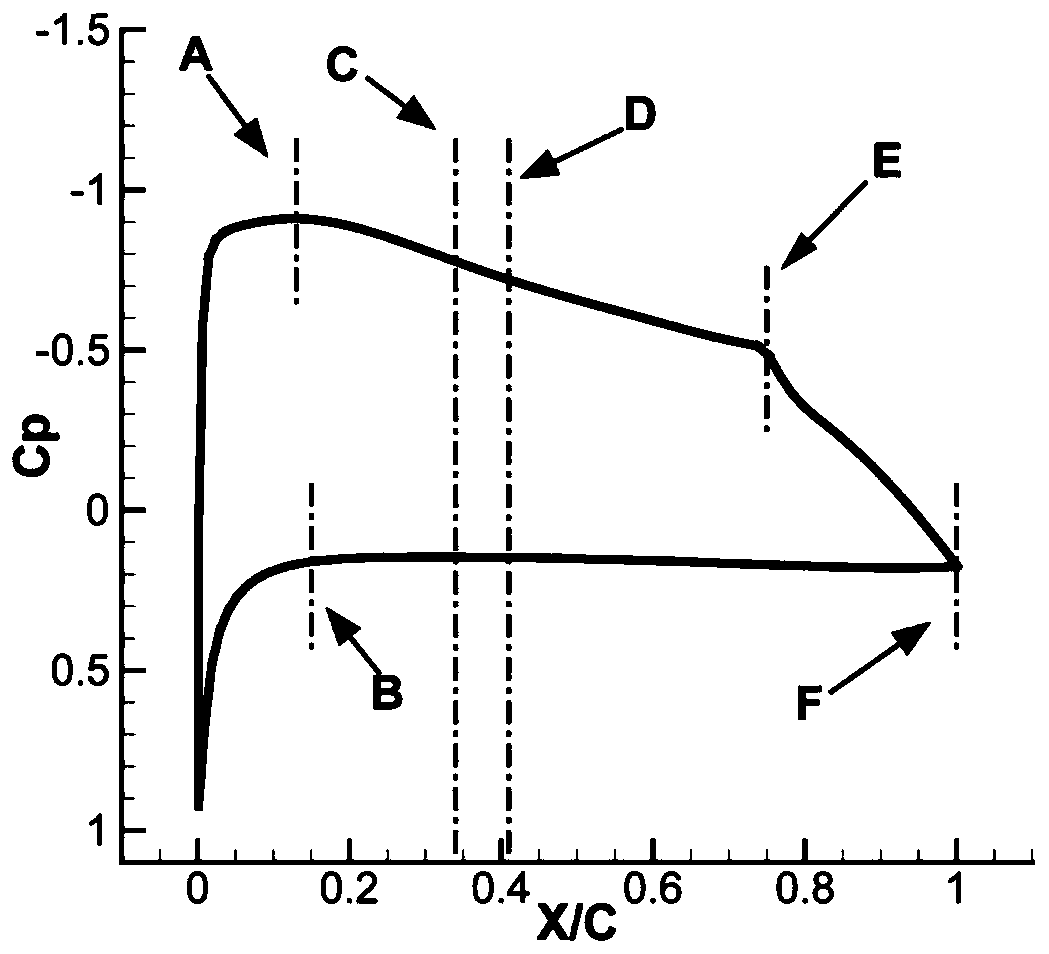

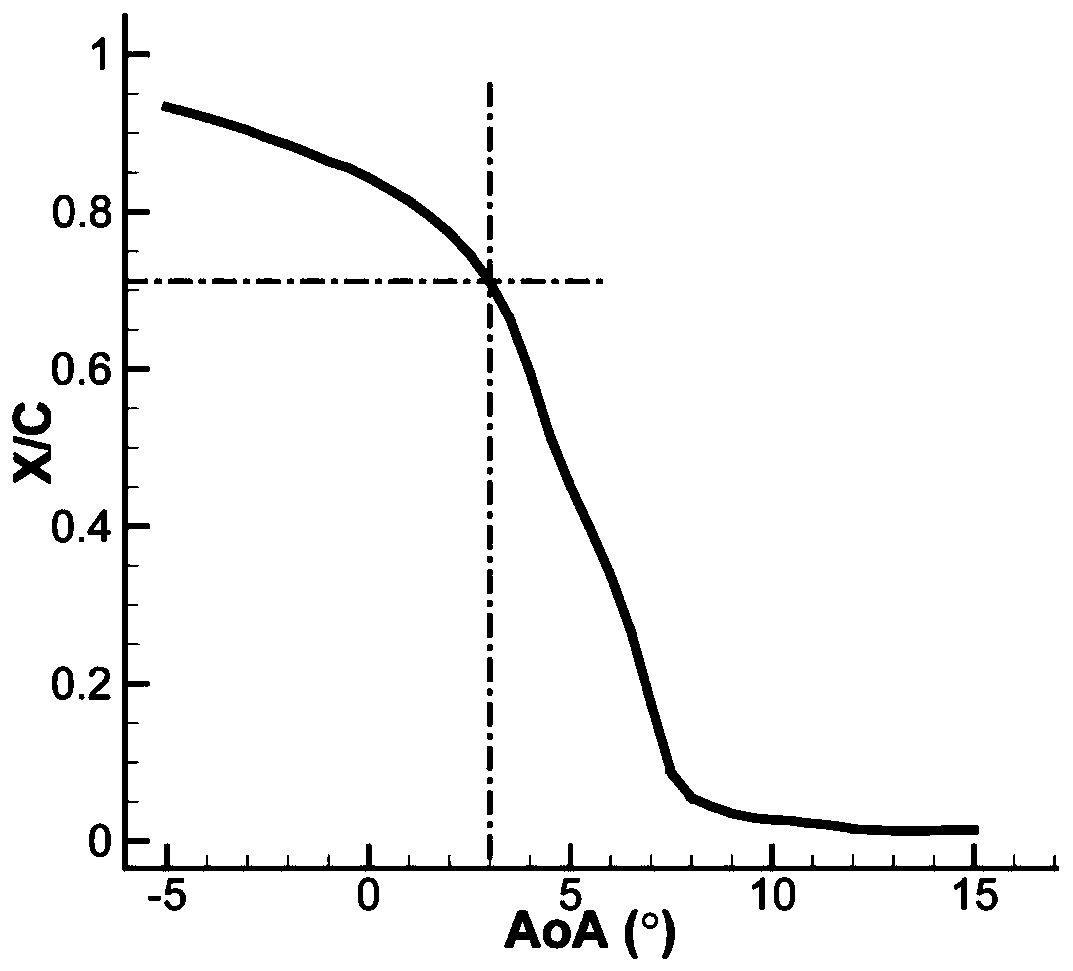

[0049]Under the condition of low Reynolds number, the surface laminar flow separation phenomenon of the conventional airfoil is serious, the lift-drag characteristics of the airfoil are seriously deteriorated, and in the state of high lift, it has a large nose-down moment; while the laminar airfoil has a large The range of laminar flow leads to a large reverse pressure gradient in the tail pressure recovery, which is easy to cause separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com