Steel bar connecting method for precast concrete cross beam and precast concrete vertical component

A technology of prefabricated concrete and vertical components, which is applied in the direction of building components, structural elements, building reinforcements, etc. It can solve the problems of difficult control of the quality of connection nodes, large amount of cast-in-place concrete, and potential safety hazards, and achieve high connection quality. Controllable, shortened construction period, high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

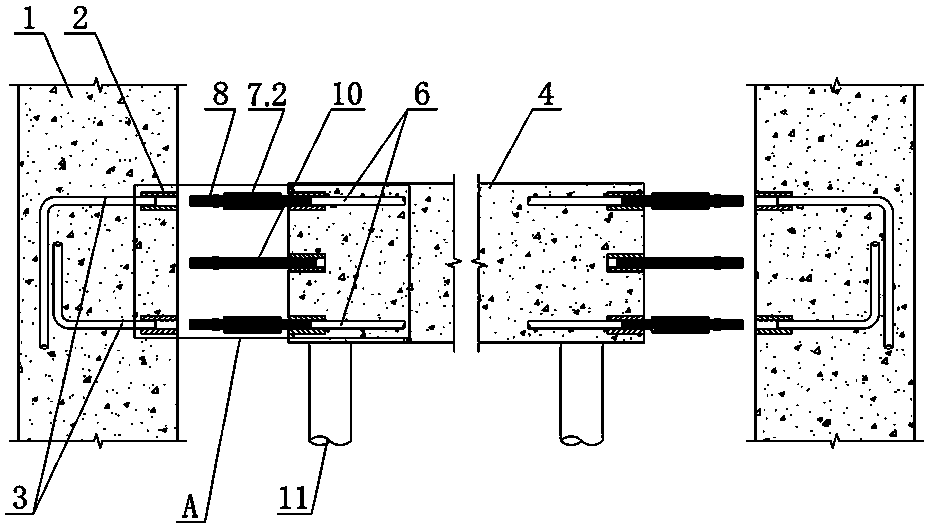

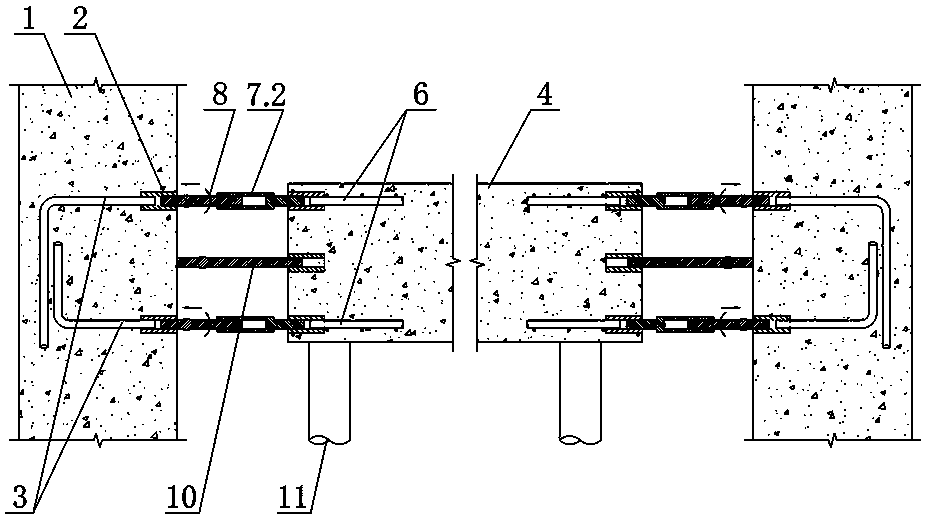

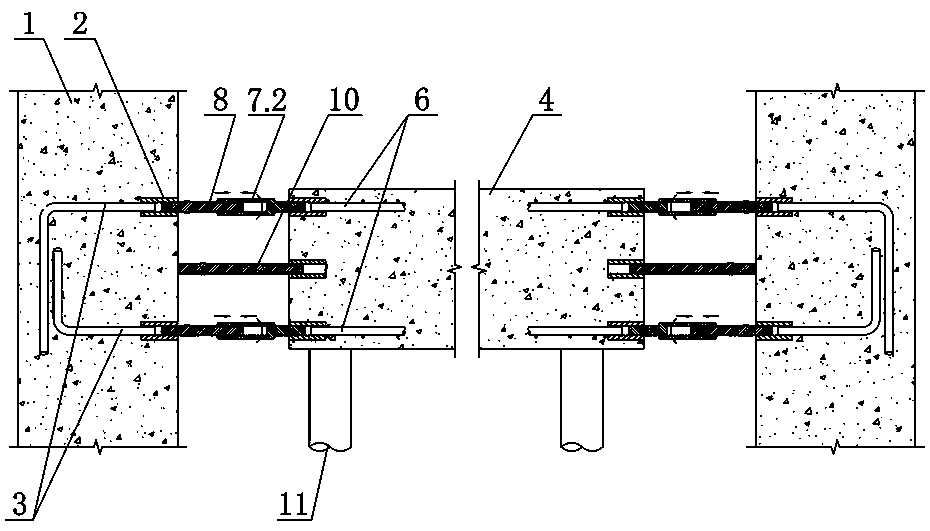

[0021] In the following, in conjunction with specific implementation methods, taking the precast concrete vertical member as a precast concrete column as an example, the connection method of the precast concrete beam and two precast concrete columns of the present invention will be further described.

[0022] The steel bar connection method of the prefabricated concrete beam and the concrete column of the present invention comprises the following steps:

[0023] In the first step, precast concrete columns 1, such as figure 1 , 5 As shown, in the connection surface of each precast concrete column 1, two rows of positive thread sleeves 2 are pre-embedded at intervals up and down, and one end of each positive thread sleeve 2 located in the precast concrete column 1 is connected to one end of the precast concrete column 1. The longitudinal steel bar 3 is fixed as a whole (when prefabricated, the positive thread sleeve 2 is set on the end of the longitudinal steel bar 3, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com